Pelleting extruder for FEP powder

An extruder and granulation technology, applied in the field of FEP powder processing equipment, can solve the problems of long processing time, shell corrosion, and high equipment requirements, and achieve the effect of simplifying the production process, saving production costs, and excellent product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

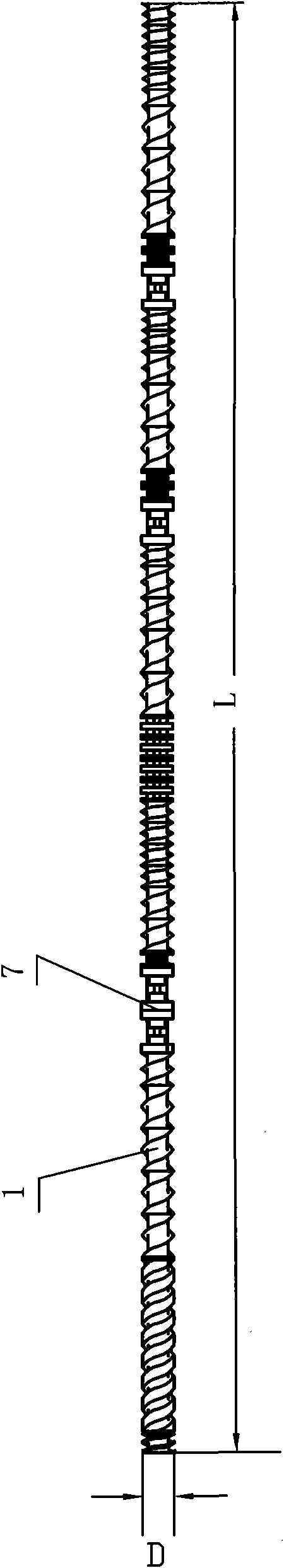

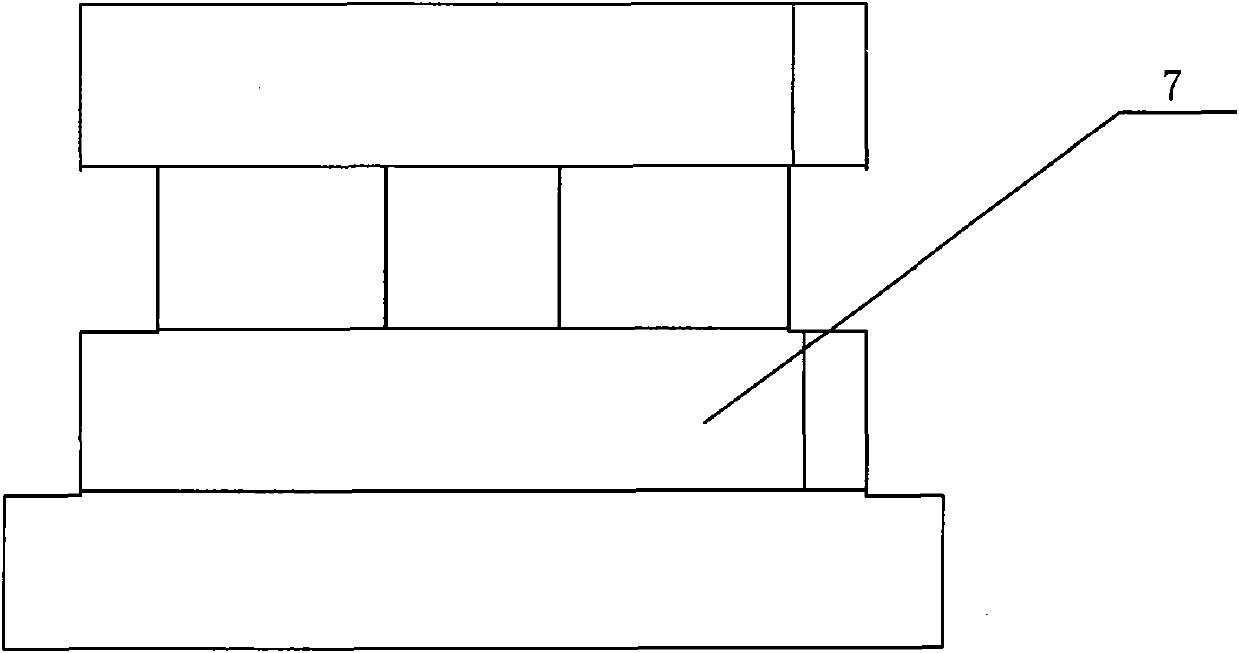

[0029] As shown in the figure, the special twin-screw extruder for processing FEP powder includes two parallel screws 1, a barrel 2 outside the screw 1, a heating system 3, and a cooling system 4, and the barrel 2 is set Fluorine gas is added to port 5 and evacuated devolatilization system 6. The length-to-diameter ratio of the screw 1 is L / D=70, and the screw 1 is composed of multi-stage shearing mixing elements, and the shearing mixing elements are composed of special diamond-shaped kneading blocks 7 with staggered angles of 45°.

[0030] In general, the FEP twin-screw extruder does not have an integrated fluorination system, and only realizes the functions of devolatilization and granulation of materials. The special-purpose twin-screw extruder for FEP powder of the present invention integrates the fluorine gas inlet 5, which is similar to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com