Rounding device for direct rounding of a square strip of an optical lens and method for direct rounding with rounding device

A round and square technology, applied in the direction of grinding/polishing equipment, metal processing equipment, machine tools designed for grinding the rotating surface of workpieces, etc., can solve labor-consuming and time-consuming, low work efficiency, and restrict the production and development of modern optical lenses, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

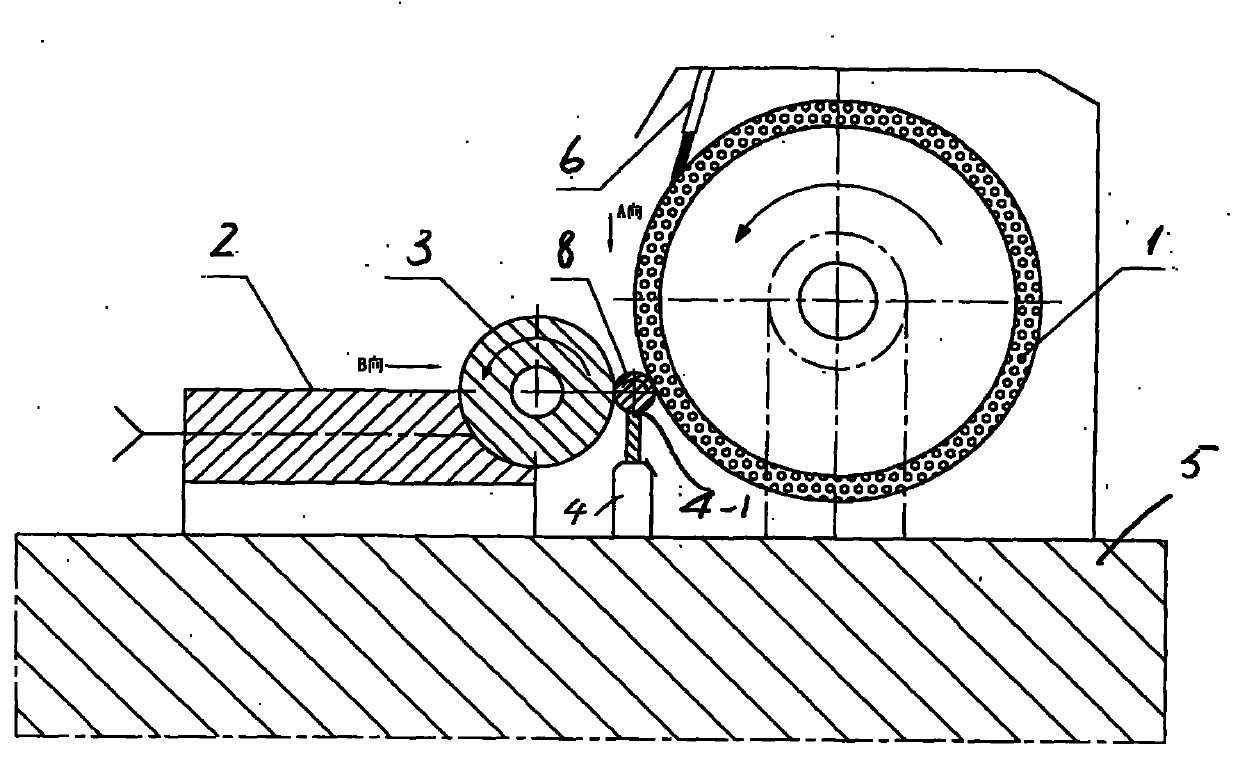

[0027] Specific implementation mode two, please refer to the attached figure 1 .

[0028] A method for directly spheronizing a square strip of optical glass by using a spheronizing device as described in one of the specific embodiments, using the square strip of optical glass as a workpiece, the direct spheronizing method includes:

[0029] a. Preliminarily adjust the relative distance between the triangular area formed by the grinding wheel 1, the guide wheel 3 and the pallet 4 according to the specific size of the optical glass square strip; and place the processed part in the place Within the triangle area;

[0030] b. Coarsely adjust the inclination angle α between the axis of the guide wheel 3 and the horizontal plane, so that the inclination angle is 0.5°~1.5°, and roughly adjust the angle β between the axes of the grinding wheel 1 and the guide wheel 3 to make the included angle β is 2°~4°; and the workpiece is pushed into the triangular area; the length of the workpiece into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com