Method for producing stainless steel welded pipes with patterns

A production method and stainless steel technology, applied in decorative arts, embossed ornaments, etc., can solve the problems of low production efficiency, complicated production process, high production cost, and achieve the effect of reducing the rollable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

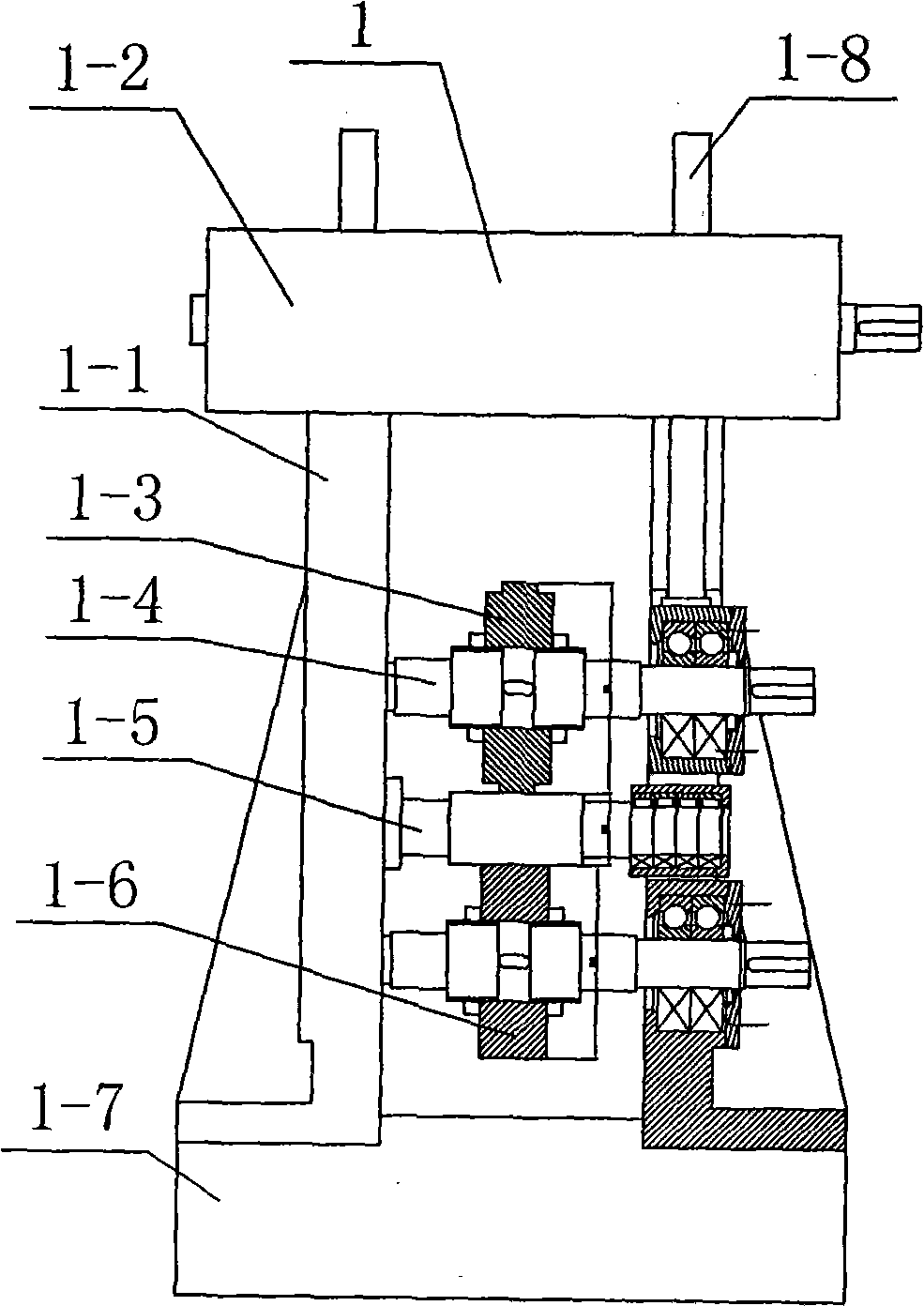

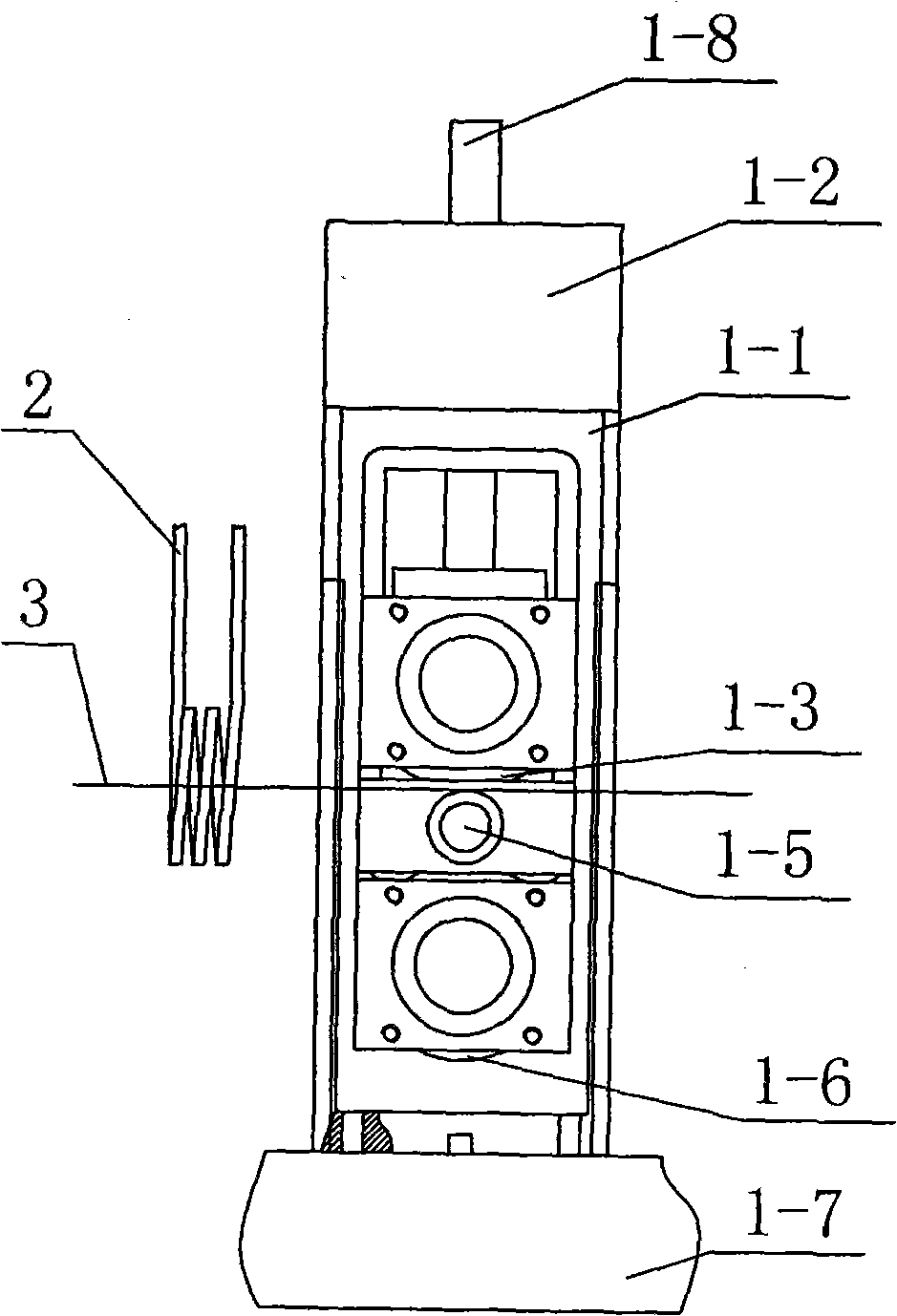

[0025] ginseng is figure 1 , figure 2 , image 3 As shown, a kind of production method step of stainless steel pattern welded pipe is like this:

[0026] (1) heating the stainless steel strip 3 with a rectangular intermediate frequency induction heating coil 2, the heating temperature is 1000-1200°C;

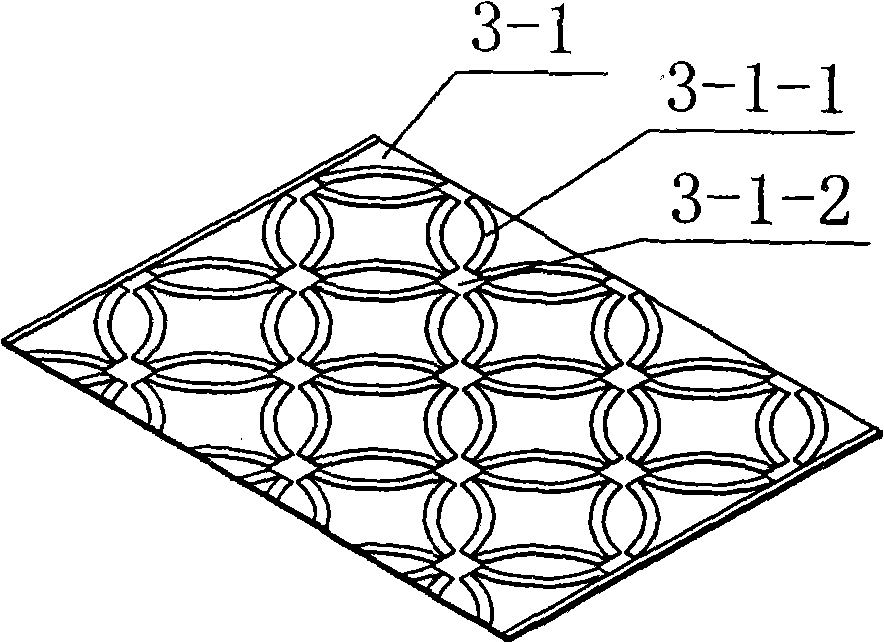

[0027] (2) The heated stainless steel strip 3 is continuously produced intermittently by a three-roll asynchronous hot-rolling mill 1, and the upper roll 1-3 of the three-roll asynchronous hot-rolling mill 1 is an active carving roll. The middle roll 1-5 is a passive smooth working roll, the lower roll 1-6 is an active smooth support roll, and the outer diameter ratio of the upper roll 1-3, middle roll 1-5, and lower roll 1-6 is 1:0.2- 0.4∶0.8-1, the speed ratio of upper roller 1-3 and lower roller 1-6 is 1∶0.9-0.6, the depth of engraving is 0.2-2.7mm, and the width left on both sides of the stainless steel belt 3 is 0.8-1.2mm the welding area;

[0028] (3) The rectangular...

Embodiment 2

[0034] see Figure 4 , Figure 5 As shown, this example is a stainless steel welded pipe with zigzag embossing on the inner surface 3-2, the cross section of the inner wall of the pipe is zigzag grooved 3-2-1, the outer diameter of the engraving roller 1-3 is φ170mm, and the middle roller 1-5 The outer diameter of the lower roller 1-6 is φ42mm, the outer diameter of the lower roller 1-6 is φ170mm, the width is 21.2mm, the thickness of the stainless steel belt 3 is 0.7mm, the depth of the groove 3-2-1 is 0.3mm, the distance between adjacent grooves is 0.36mm, and the tooth top is wide is 0.22mm, tooth bottom width is 0.268mm, tooth tip angle is 9°, the included angle between flute 3-2-1 and steel strip longitudinal angle is 25°, zigzag flute 3-2-1 is in addition to stainless steel welded pipe Outside the weld area, all are filled. Leave 1 mm on both sides of the weld without rolling, and the outer wall of the welded pipe is smooth. The speed ratio of upper and lower rolls 1-...

Embodiment 3

[0036] see Image 6 As shown, this example is a T-shaped embossed stainless steel welded pipe 3-3 on the outer surface, the surface of the welded pipe is covered with T-shaped embossed lines 3-3-1, and multiple rows of T-shaped embossed lines 3-3-1 are arranged one by one along one direction. The height of the outer embossment is 0.4mm, the thickness of the stainless steel strip is 0.8mm, the outer diameter of the upper roll 1-3 is φ170mm, the outer diameter of the middle roll 1-5 is φ34mm, the outer diameter of the lower roll 1-6 is φ152mm, both sides of the weld Leave 1.2mm unrolled on each edge, and roll T-shaped reliefs 3-3-1 on the rest. The inner wall of the welded pipe is smooth. The rotational speed ratio of upper roll 1-3 and lower roll 1-6 is 1: 0.8. Its groove rolling method is as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com