A kind of cold rolling emulsion with iron powder self-dispersing performance and preparation method thereof

An emulsion and self-dispersing technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of product quality and energy waste, achieve high oil film strength, improve the cleanliness of the board surface, and improve the antirust performance of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

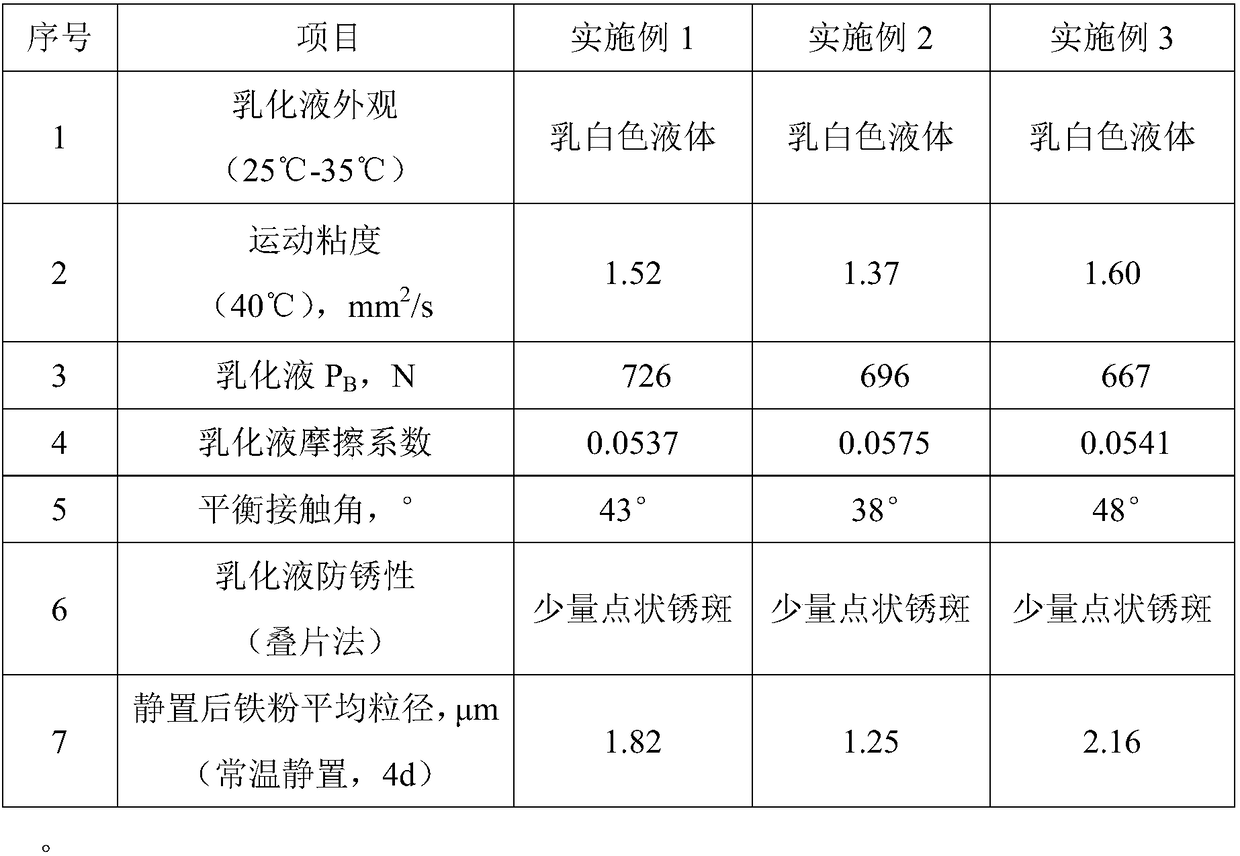

Examples

Embodiment 1

[0014] Embodiment 1 formula sees the following table:

[0015] serial number

component name

Weight (g)

1

Dipentaerythritol Oleate

2.8

2

naphthenic oil

1.8

3

Span60

0.2

4

Tween60

0.2

5

Molybdenum Dialkyl Dithiophosphate

0.3

6

Monoglyceride Oleate

0.3

7

Lead dibutylthiocarbamate

0.2

8

0.1

9

Sodium dinaphthyl methane disulfonate

0.3

10

0.4

11

Deionized water

93.4

[0016] According to the weight formula of each component in the above table, a new self-dispersing iron powder type cold rolling emulsion was prepared. Dipentaerythritol oleate (2.8g), naphthenic oil (1.8g), dialkyl molybdenum dithiophosphate (0.3g), oleic acid monoglyceride (0.3g), dibutyl lead thiocarbamate (0.2g) and sodium petroleum sulfonate (0.1g), after adding into the beaker in sequence, put it on a co...

Embodiment 2

[0020] Embodiment 2 formula sees the following table:

[0021] serial number

component name

Weight (g)

1

Dipentaerythritol Oleate

3.8

2

naphthenic oil

2.3

3

Span60

0.2

4

Tween60

0.2

5

Molybdenum Dialkyl Dithiophosphate

0.5

6

Monoglyceride Oleate

0.5

7

Lead dibutylthiocarbamate

0.2

8

0.1

9

Sodium dinaphthyl methane disulfonate

0.5

10

0.6

11

Deionized water

91.1

[0022] According to the weight formula of each component in the above table, a new self-dispersing iron powder type cold rolling emulsion was prepared. Dipentaerythritol oleate (3.8g), naphthenic oil (2.3g), dialkyl molybdenum dithiophosphate (0.5g), oleic acid monoglyceride (0.5g), dibutyl lead thiocarbamate (0.2g) and sodium petroleum sulfonate (0.1g), after being added to the beaker in sequence, be placed o...

Embodiment 3

[0026] Embodiment 3 formula sees the following table:

[0027] serial number

component name

Weight (g)

1

Dipentaerythritol Oleate

3.0

2

naphthenic oil

1.4

3

Span60

0.2

4

Tween60

0.2

5

Molybdenum Dialkyl Dithiophosphate

0.3

6

Monoglyceride Oleate

0.3

7

Lead dibutylthiocarbamate

0.2

8

Sodium petroleum sulfonate

0.1

9

Sodium dinaphthyl methane disulfonate

0.2

10

0.2

11

Deionized water

93.9

[0028] According to the weight formula of each component in the above table, a new self-dispersing iron powder type cold rolling emulsion was prepared. Dipentaerythritol oleate (3.0g), naphthenic oil (1.4g), molybdenum dialkyldithiophosphate (0.3g), monoglyceride oleate (0.3g), lead dibutylthiocarbamate (0.2g) and sodium petroleum sulfonate (0.1g), after being added to the beaker in sequence, be placed on a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com