A kind of antibacterial rolling emulsion containing nano tio2 and preparation method thereof

A kind of emulsion and nanotechnology, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems that affect the performance and service life, increase the burden on the environment, reduce the qualified rate of products, etc., and achieve good antibacterial and anticorruption performance, Improve the surface quality of the product and improve the effect of anti-rust performance of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

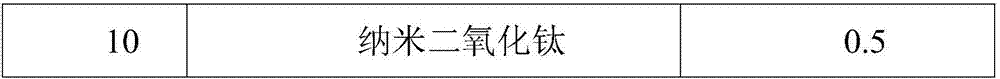

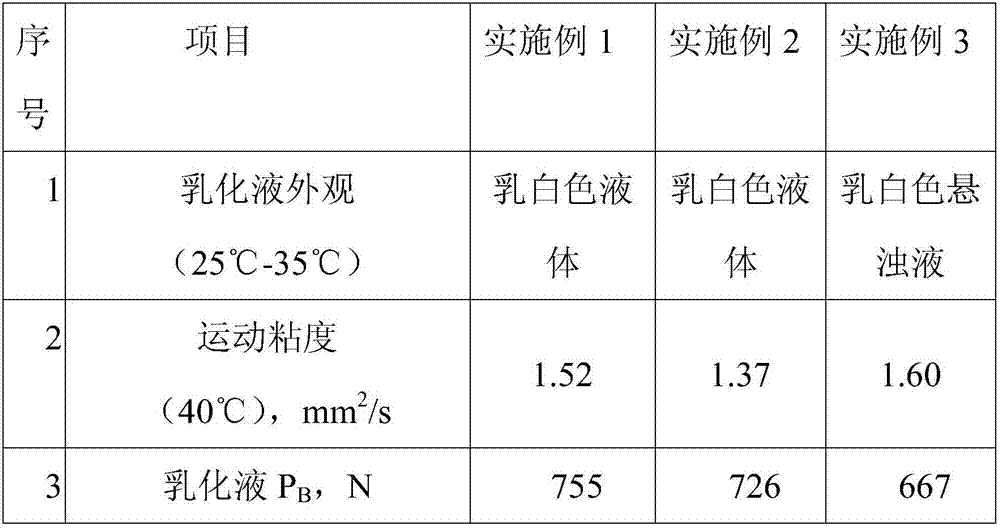

[0013] Embodiment 1 formula sees the following table:

[0014]

[0015]

[0016] According to the weight formula of each component in the above table, prepare nano-TiO 2 antibacterial cold-rolled emulsion. Add pentaerythritol oleate (1.0g), isooctyl palmitate (1.8g), sodium petroleum sulfonate (0.1g), and sulfurized fatty acid (0.3g) into the beaker in order, and put them on the constant temperature electromagnetic stirrer Heat to 80°C while stirring, and keep stirring at constant temperature for 10 minutes. Cool to 70°C, then add Span80 (0.2g), Tween80 (0.2g), and stir at constant temperature for 25 minutes to obtain cold-rolled emulsified oil for strip steel, add it to deionized water, stir at constant temperature for 15 minutes, and cool to room temperature. That is, the basic cold rolling emulsion is obtained.

[0017] At room temperature, sodium hexametaphosphate (1.0g), nano-TiO 2 (0.5g) was added to the basic cooling emulsion in turn, and the stirring speed wa...

Embodiment 2

[0020] Embodiment 2 formula sees the following table:

[0021] serial number

component name

Weight (g)

1

pentaerythritol oleate

1.0

2

isooctyl palmitate

1.8

3

Span80

0.2

4

Tween80

0.2

5

sulfurized fatty acid

0.3

6

0.1

7

Hexametaphosphate

1.3

8

Ethylene glycol

10.5

9

Deionized water

84.3

10

Nano Titanium Dioxide

0.3

[0022] According to the weight formula of each component in the above table, prepare nano-TiO 2 antibacterial cold-rolled emulsion. Add pentaerythritol oleate (1.0g), isooctyl palmitate (1.8g), sodium petroleum sulfonate (0.1g), and sulfurized fatty acid (0.3g) into the beaker in order, and put them on the constant temperature electromagnetic stirrer Heat to 80°C while stirring, and keep stirring at constant temperature for 10 minutes. Cool to 60°C, then add Span80 ...

Embodiment 3

[0026] Embodiment 3 formula sees the following table:

[0027] serial number

component name

Weight (g)

1

pentaerythritol oleate

1.0

2

isooctyl palmitate

1.8

3

Span80

0.2

4

Tween80

0.2

5

sulfurized fatty acid

0.3

6

0.1

7

Hexametaphosphate

1.5

8

Ethylene glycol

12

9

Deionized water

82.1

10

Nano Titanium Dioxide

0.8

[0028] According to the weight formula of each component in the above table, configure nano-TiO 2 antibacterial cold-rolled emulsion. Add pentaerythritol oleate (1.0g), isooctyl palmitate (1.8g), sodium petroleum sulfonate (0.1g), and sulfurized fatty acid (0.3g) into the beaker in order, and put them on the constant temperature electromagnetic stirrer Heat to 80°C while stirring, and keep stirring at constant temperature for 10 minutes. Cool to 60°C, then add Span80 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com