Catalyst with non-oxide as carrier and application thereof

A non-oxide and catalyst technology, applied in physical/chemical process catalysts, compressed gas generation, chemical/physical processes, etc., can solve the problems that silicon carbide or silicon nitride catalysts have not been reported, and achieve good catalytic decomposition activity and low-temperature activity, mild reaction conditions, and wide synthesis temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

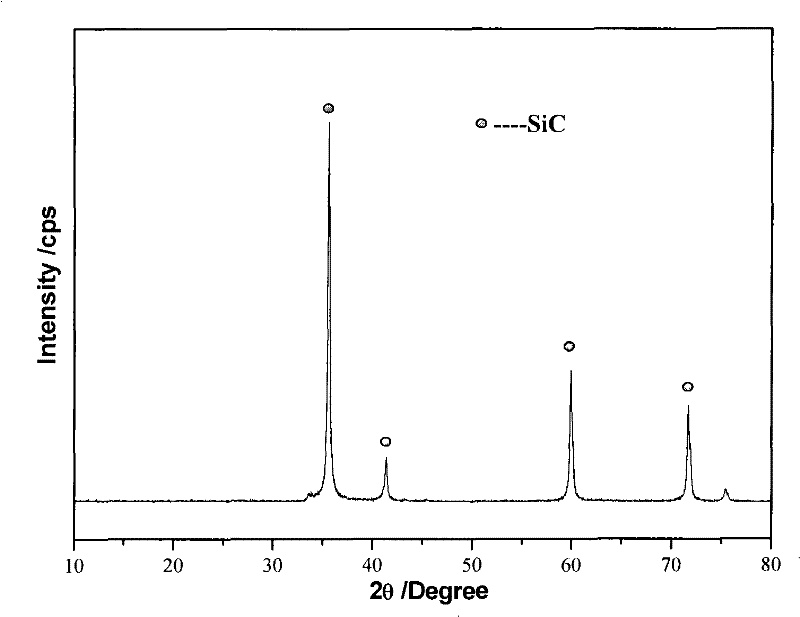

[0043]Preparation of SiC carrier: Dissolve 12.5g of glucose in 15mL of water, then pour it into 50mL of ethanol solution containing 8.5g of VTMS to form a mixture; add 0.4g of citric acid and 0.2g of ferric nitrate, stir rapidly at 30°C for 24 hours to form a gel, and dried overnight at 80°C; then calcined at 1400°C for 10 hours under an argon atmosphere, and 800°C for 2 hours under an air atmosphere, soaked in 30wt% NaOH, washed, and dried to obtain a SiC carrier. The obtained carrier has a typical silicon carbide structure with a large specific surface of 42.1m 2 g -1 , its XRD results are as follows figure 1 As shown, the specific surface results are shown in Table 1.

Embodiment 2

[0045] Compared with Example 1, the difference is that the gelling reaction temperature is 50° C., and the amount of other materials and operating conditions are the same as in Example 1. The specific surface results are shown in Table 1.

Embodiment 3

[0047] Compared with Example 1, the difference is that the gelling reaction temperature is 80° C., and the amount of other materials and operating conditions are the same as in Example 1. The specific surface results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com