Support for separation membrane, and method for production thereof

A manufacturing method and separation membrane technology, which are applied in chemical instruments and methods, semi-permeable membrane separation, textiles and papermaking, etc., can solve the problems of defects, uneven membranes, and high manufacturing costs, and achieve suppression of deformation, excellent uniformity, The effect of high water production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

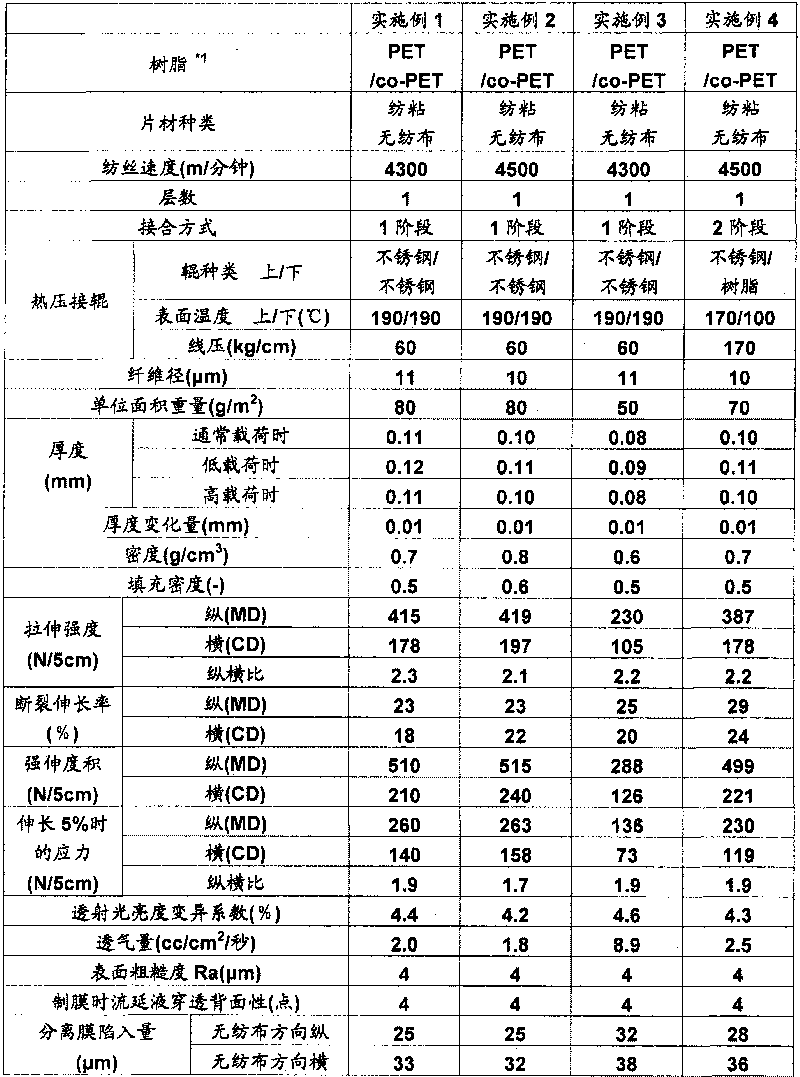

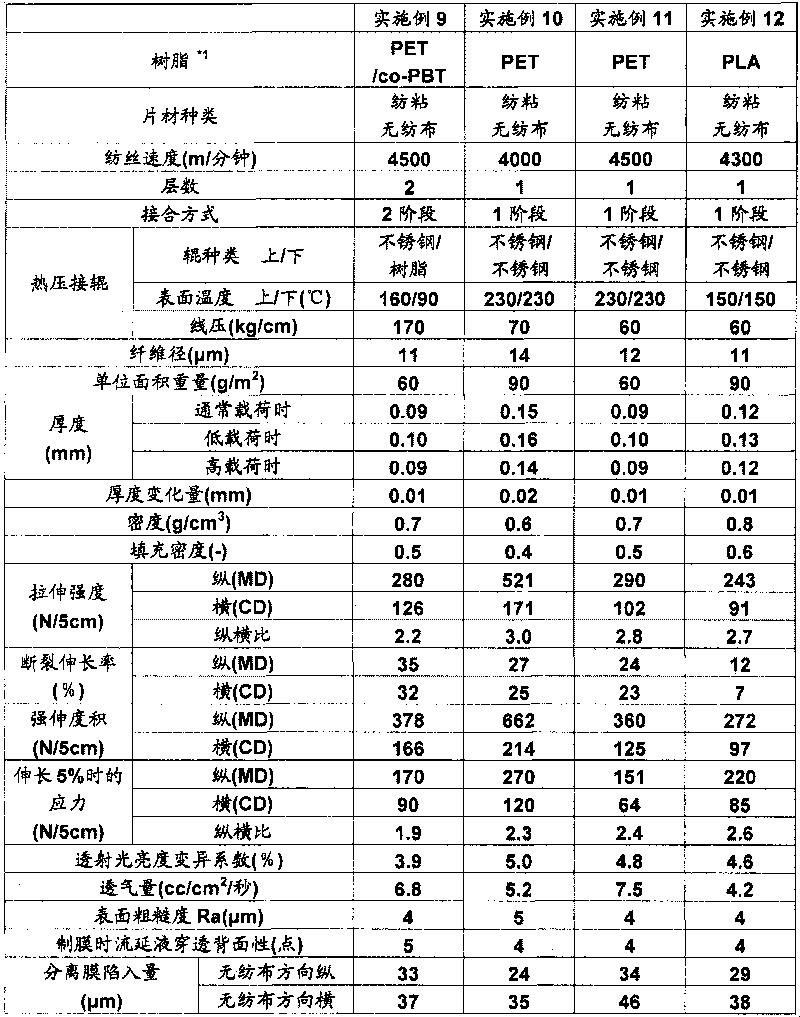

Embodiment 1

[0186] Prepare polyethylene terephthalate resin (a) and copolyester resin (b), described polyethylene terephthalate resin (a) is dried to moisture content below 50ppm, and its intrinsic viscosity The IV is 0.65, the melting point is 260°C, and contains 0.3% by weight of titanium oxide, the copolyester resin (b) is dried to a moisture content of 50 ppm or less, the intrinsic viscosity IV is 0.66, and the copolymerization ratio of isophthalic acid is 10 mol%, melting point is 230°C, and contains 0.2% by weight of titanium oxide.

[0187] The above-mentioned polyethylene terephthalate resin (a) was melted at a temperature of 295°C, and the copolyester resin (b) was separately melted at a temperature of 280°C to form polyethylene terephthalate Alcohol ester resin (a) is the core component, and copolyester resin (b) is the sheath component, and the core: sheath = 80:20 weight ratio is spun from the pores at a nozzle temperature of 300 ° C, and then passed through An ejector (Eject...

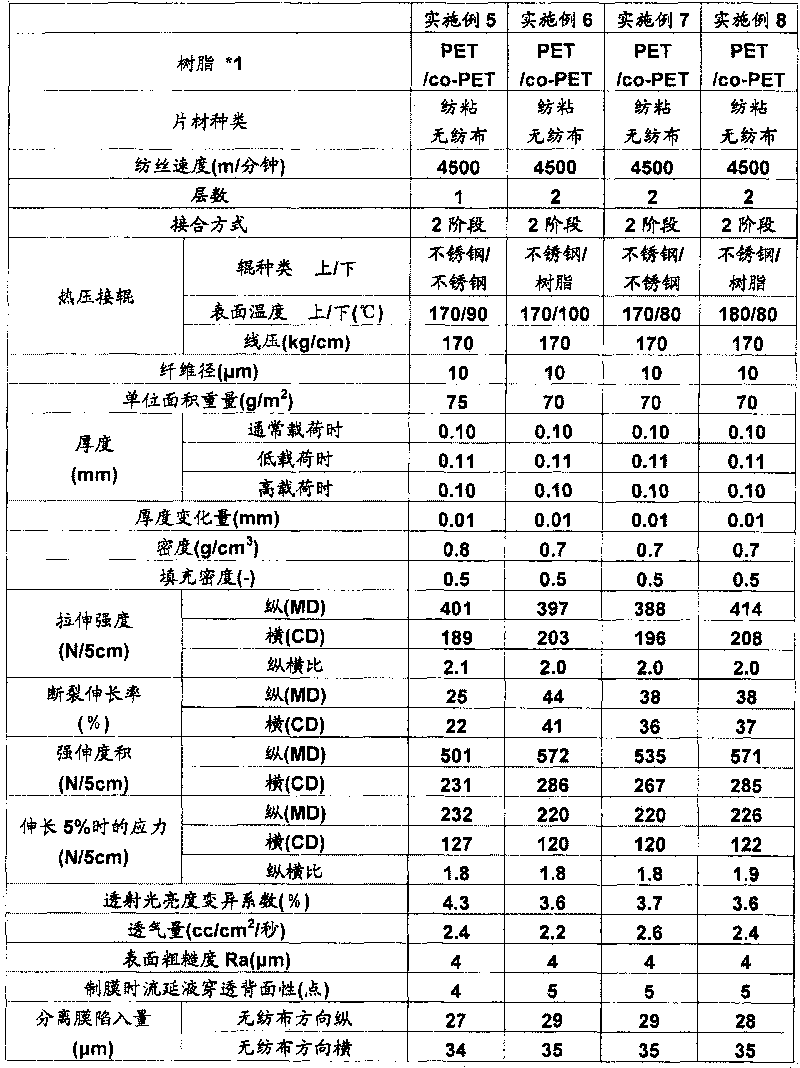

Embodiment 2

[0189]The polyethylene terephthalate resin (a) used in Example 1 was melted at a temperature of 295° C., and the copolyester resin (b) was separately melted at a temperature of 280° C. The ethylene glycol phthalate resin (a) is the core component, and the copolyester resin (b) is the sheath component, and the nozzle temperature is 300° C., and the core: sheath = 80:20 by weight ratio. The fine holes are spun out, and then spun by an injector at a spinning speed of 4500m / min to form concentric core-sheath long fibers with a circular cross-section, which are collected as a fiber web on a moving mesh conveyor belt. The collected fiber web is clamped between a pair of upper and lower stainless steel flat rolls, and thermocompression bonding is carried out at the surface temperature of each flat roll at 190°C and a linear pressure of 60kg / cm to produce continuous long fiber fibers The diameter is 10μm, and the weight per unit area is 80g / m 2 , a spunbonded nonwoven fabric with a t...

Embodiment 3

[0191] The polyethylene terephthalate resin (a) used in Example 1 was melted at a temperature of 295° C., and the copolyester resin (b) was separately melted at a temperature of 280° C. Ethylene phthalate resin (a) is the core component, and copolyester resin (b) is the sheath component, and the temperature of the nozzle is 300 ° C, and the core: sheath = 85:15 under the condition of the weight ratio. The fine holes are spun out, and then spun by an injector at a spinning speed of 4300m / min to form concentric core-sheath long fibers with a circular cross-section, which are collected as a fiber web on a moving mesh conveyor belt. The collected fiber web is clamped between a pair of upper and lower stainless steel flat rolls, and thermocompression bonding is carried out at the surface temperature of each flat roll at 190°C and a linear pressure of 60kg / cm to produce continuous long fiber fibers The diameter is 11μm, and the weight per unit area is 50g / m 2 , a spunbond nonwoven ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com