Cathode materials for carbon nano-tube composite lithium ion battery and preparation method thereof

A carbon nanotube composite, negative electrode material technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problem that electrode materials cannot form a continuous three-dimensional conductive network, and achieve high production efficiency, excellent comprehensive performance, and improved permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

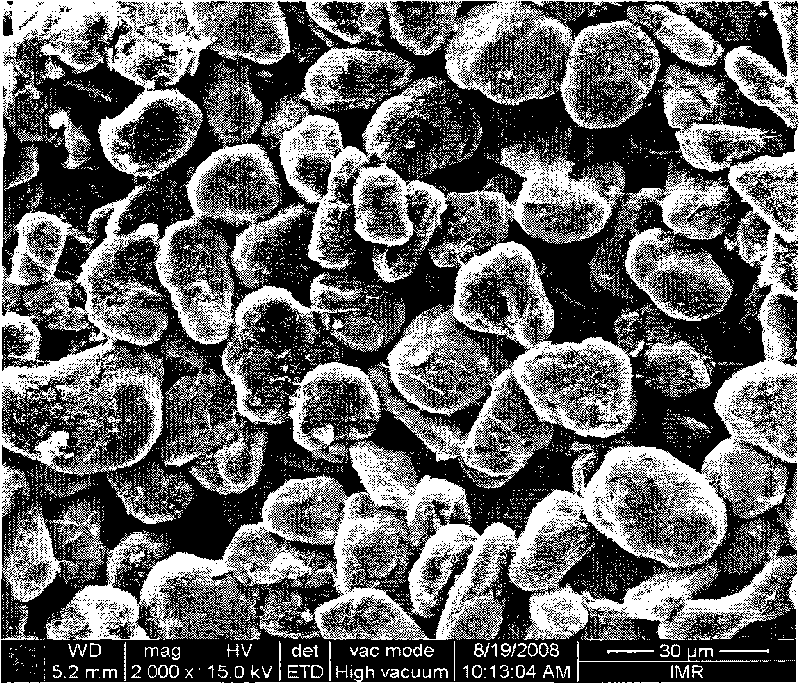

[0029] Embodiment 1: Synthetic carbon nanotube composite natural graphite negative electrode material

[0030] (1) Select carbon nanotubes with a length of 10-15 μm and a diameter of 50-150 nm as raw materials. Add 60 g of carbon nanotubes and 6 g of dispersant polyvinylpyrrolidone (PVP) into 2000 ml of deionized water; after ultrasonic dispersion, continue stirring and mixing at high speed to make a uniform dispersion of carbon nanotubes;

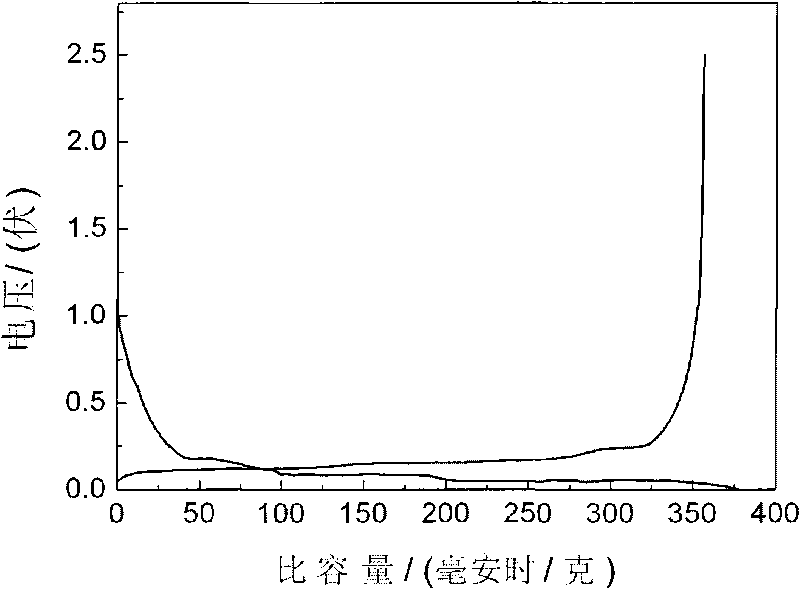

[0031] (2) with 6000g spherical natural graphite, the average particle diameter D50=19.6 μ m of natural graphite, tap density is 0.98g / cm 3 , with a specific surface area of 6.4m 2 / g, particle diameter is less than 5 μ m particle cumulative volume ratio is 3.1%, (002) interplanetary distance is 0.3365nm, and 6000g deionized water, join among the uniformly dispersed 60g carbon nanotube slurry that above-mentioned step 1 obtains, adopt The three-dimensional mixer performs full mixing in the liquid state, and after drying, a uniform mixt...

Embodiment 2

[0036] Embodiment 2: Synthesis of carbon nanotube composite artificial graphite negative electrode material

[0037] (1) Select carbon nanotubes with a length of 10-15 μm and a diameter of 50-150 nm as raw materials. Add 60 g of carbon nanotubes and 6 g of dispersant polyvinylpyrrolidone (PVP) into 2000 ml of deionized water; continue stirring and mixing at high speed after ultrasonic dispersion to make a uniform dispersion of carbon nanotubes;

[0038] (2) With 6000g artificial graphite, the average particle diameter D50=15.2 μm of artificial graphite, tap density is 0.98g / cm 3 , the specific surface area is 4.59m 2 / g, the distance between (002) planes is 0.3359nm, the reversible capacity of this graphite is 290mAh / g, and the first efficiency is 87.01%. Add the above-mentioned artificial graphite and 6000g of deionized water to the uniformly dispersed 60g of carbon nanotube slurry obtained in the above step 1, use a three-dimensional mixer to fully mix the liquid state, an...

Embodiment 3

[0043] Example 3: Synthesis of carbon nanotube composite mixed graphite negative electrode material

[0044] (1) Select carbon nanotubes with a length of 10-15 μm and a diameter of 50-150 nm as raw materials. Add 60 g of carbon nanotubes and 6 g of dispersant polyvinylpyrrolidone (PVP) into 2000 ml of deionized water; continue stirring and mixing at high speed after ultrasonic dispersion to make a uniform dispersion of carbon nanotubes;

[0045] (2) With 3000g spherical natural graphite, the average particle diameter of natural graphite D50=19.6 μm. And 3000g artificial graphite, the average particle diameter D50=15.2 μ m of artificial graphite, and 6000g deionized water, join among the uniformly dispersed 60g carbon nanotube slurry that above-mentioned step 1 obtains, adopt three-dimensional mixer to carry out liquid state and fully mix, After drying, a uniform mixture of artificial graphite, natural graphite and carbon nanotubes is obtained.

[0046] (3) Take 600 g of petr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com