Method and production system for preparing solid toilet cleaning blocks by tablet pressing method

A technology of toilet cleaning block and tablet pressing method, which is applied in the direction of forming soap, mixing/kneading soap, etc., which can solve problems such as difficulty in continuous production, product quality defects, and easy generation of dust, so as to achieve continuous production and shorten the production cycle , the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

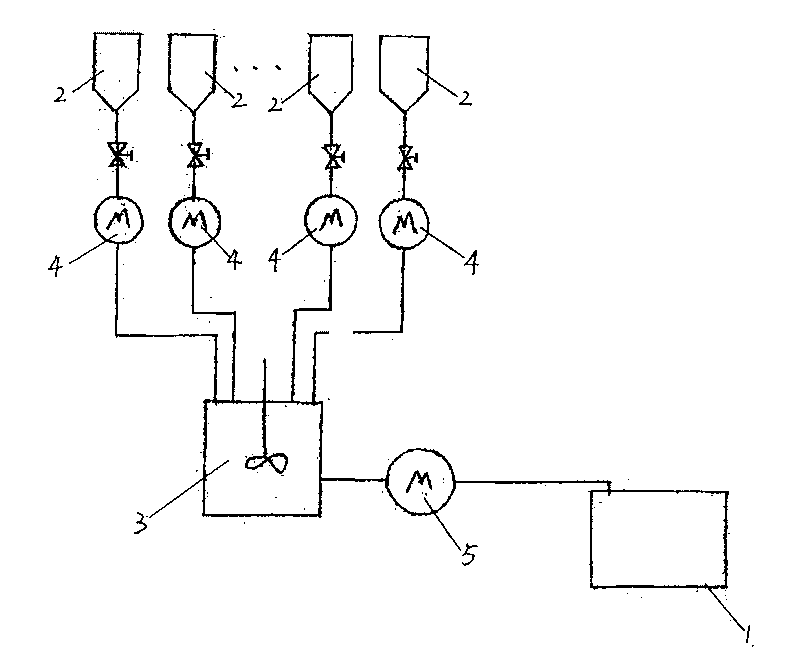

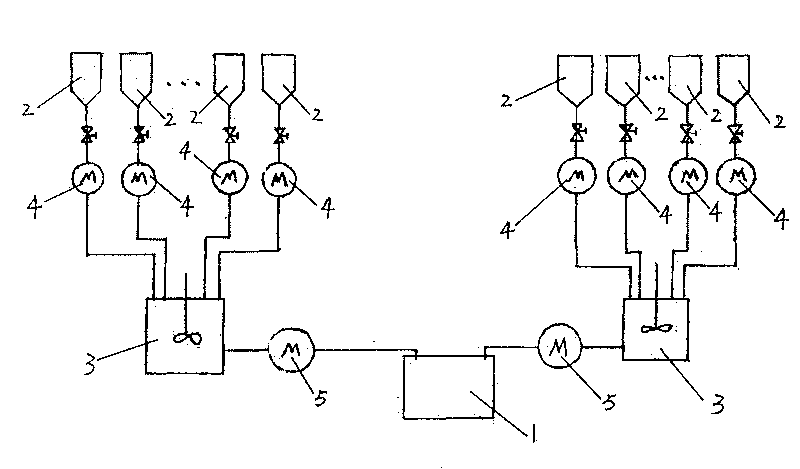

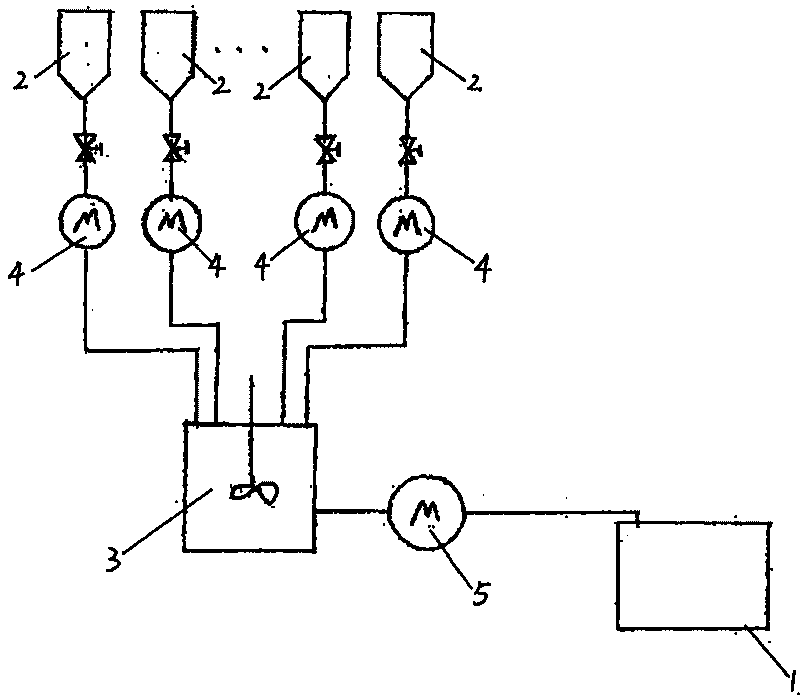

[0047] figure 1 The production system shown is an embodiment of the present invention. A production system for solid toilet blocks by the tablet method is composed of a tablet press 1 and a set of raw material processing equipment connected; the tablet press 1 includes Feeder, mold and stamping mechanism; the raw material processing equipment consists of 7 raw material storage tanks 2, 7 metering devices 4 and a mixer 3, each raw material storage tank 2 is connected with the corresponding meter 4, and the meter 4 is then connected with the mixer 3 connection, the mixer 3 is connected with the tablet press 1 through a pipe, a meter 5 and a conveying device (not shown in the figure).

[0048] The conveying device adopts a screw conveyor.

[0049] The tablet press 1 can be a single-punch tablet press or a rotary tablet press. The die and punch of the tablet press 1 are mirror polished.

Embodiment 2

[0051] Preparation of toilet block:

[0052] ingredient

Total dry material (wt%)

71.00

10.00

Anionic surfactant

6.00

Non-ionic surfactant

4.00

Polymer Surfactant

6.00

dye

2.00

spices

1.00

[0053] The solid toilet block production system provided in Example 1 is used to prepare the solid toilet block.

[0054] (1) Put various raw materials into different raw material storage tanks 2, and then measure the weight of various raw materials according to the formula of the toilet block and send them to the mixer 3 to mix evenly to obtain mixed dry materials, and then add the mixed dry materials 15% of the total weight of water is mixed uniformly to obtain a granular mixture.

[0055] (2) The mixture material in step (1) is measured, and then conveyed to the cavity of the mold of the tablet press 1 via a screw conveyor, and molded with a pressure of 60 Kgf to obtain a toilet block.

Embodiment 3

[0057] Preparation of toilet block:

[0058] ingredient

Total dry material (wt%)

Sodium sulfate

61.00

10.00

Anionic surfactant

12.00

[0059] ingredient

Total dry material (wt%)

Non-ionic surfactant

4.00

Polymer Surfactant

10.00

dye

2.00

spices

1.00

[0060] The solid toilet block production system provided in Example 1 is used to prepare the solid toilet block.

[0061] (1) Put various raw materials into different raw material storage tanks 2, and then measure the weight of various raw materials according to the formula of the toilet block and send them to the mixer 3 to mix evenly to obtain mixed dry materials, and then add the mixed dry materials Magnesium stearate with a total weight of 2‰ is continued to be stirred uniformly, and 12% of the total weight of the mixed dry material is added to mix uniformly to obtain a granular mixture.

[0062] (2) The mixture material in step (1) is measured, and then conveyed to the cavity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com