Tungsten ore floatation collecting agent and application thereof

A collector and flotation technology, used in flotation, solid separation, etc., can solve the problems of poor flotation collection effect, and achieve the effect of good selective collection capacity, convenient material acquisition, and improved surface activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

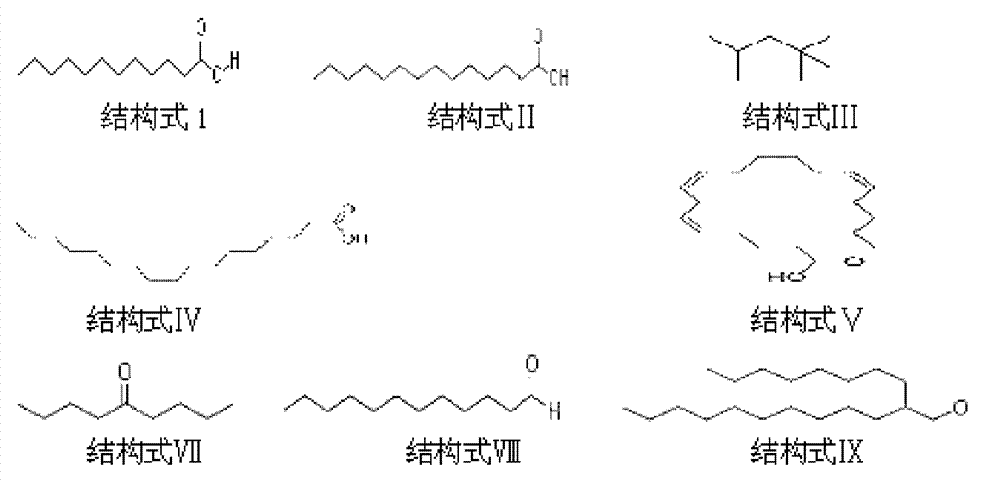

[0015] The artificial mixed ore flotation experiment was carried out on the XFG hanging tank flotation machine. The 2.0g raw ore sample weighed is a mixed sample of scheelite and calcite in a ratio of 1:1, put it into a 40ml flotation tank, add 30ml of distilled water, adjust the slurry for 1min, adjust the pH value with HCl or NaOH, and use After the PHS-3C type precision pH meter measures the pH value, add 200 grams / ton of raw ore of mixed collector of the present invention (mass proportion is: lauric acid 20%, myristic acid 20%, isooctane 10%, Oleic acid 20%, arachidonic acid 15%, 5-nonanone 5%, dodecanal 5%, iso-eicosyl ether 5%) stirring for 3 minutes, flotation for 4 minutes, the new collector can be obtained in a wide range of pH The recovery rate of scheelite is above 90%, while the recovery rate of calcite is below 40%.

Embodiment 2

[0017] For a certain ore containing black and scheelite in Hunan, the original ore contains WO 3 0.38%, take 500g raw ore by crushing and grinding, add water until the pulp contains 30% solid weight, add lime 1000 g / t raw ore, sodium carbonate 2000 g / t raw ore, water glass mixture 3500 g / t raw ore, add the present invention Described mixed collector 300 grams / ton raw ore (mass proportion is: lauric acid 20%, myristic acid 20%, isooctane 10%, oleic acid 20%, arachidonic acid 15%, 5- 5% nonanone, 5% dodecanal, 5% iso-eicosyl ether) have carried out laboratory flotation research, at room temperature after a rough three sweep four fine can be obtained black, scheelite coarse concentrate, containing WO 3 38.8%, job recovery rate 82.5%. The black tungsten and scheelite crude concentrates can be further processed to obtain commercial black tungsten concentrates and scheelite concentrates.

Embodiment 3

[0019] A small-scale test was carried out on the actual ore of a black and scheelite mine in Xinjiang, and good technical indicators were obtained. Raw ore contains WO 3 0.78%, take 500g raw ore by crushing and finely grinding, add water until the pulp contains 35% solid weight, add lime 1000 g / t raw ore, sodium carbonate 2000 g / t raw ore, water glass mixture 3500 g / t raw ore, add the present invention Described mixed collector 200 grams / ton (mass proportion is: lauric acid 15%, myristic acid 18%, isooctane 8%, oleic acid 25%, arachidonic acid 10%, 5-nonanone 8%, dodecanal 8%, iso-eicosyl ether 8%) raw ore has been carried out laboratory flotation research, after a rough separation at room temperature, tungsten rough concentrate can be obtained, containing WO 3 10.8%, and the job recovery rate is 88.3%. As a result, better flotation enrichment has been achieved, and the recovery rate of tungsten ore is also higher. It can be seen that the high-efficiency collector of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com