Coal liquefaction iron-base catalyst, preparation method thereof and method for improving yield of coal liquefaction oil

An iron-based catalyst, coal liquefied oil technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of high cost and low oil yield, and achieve high oil yield , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

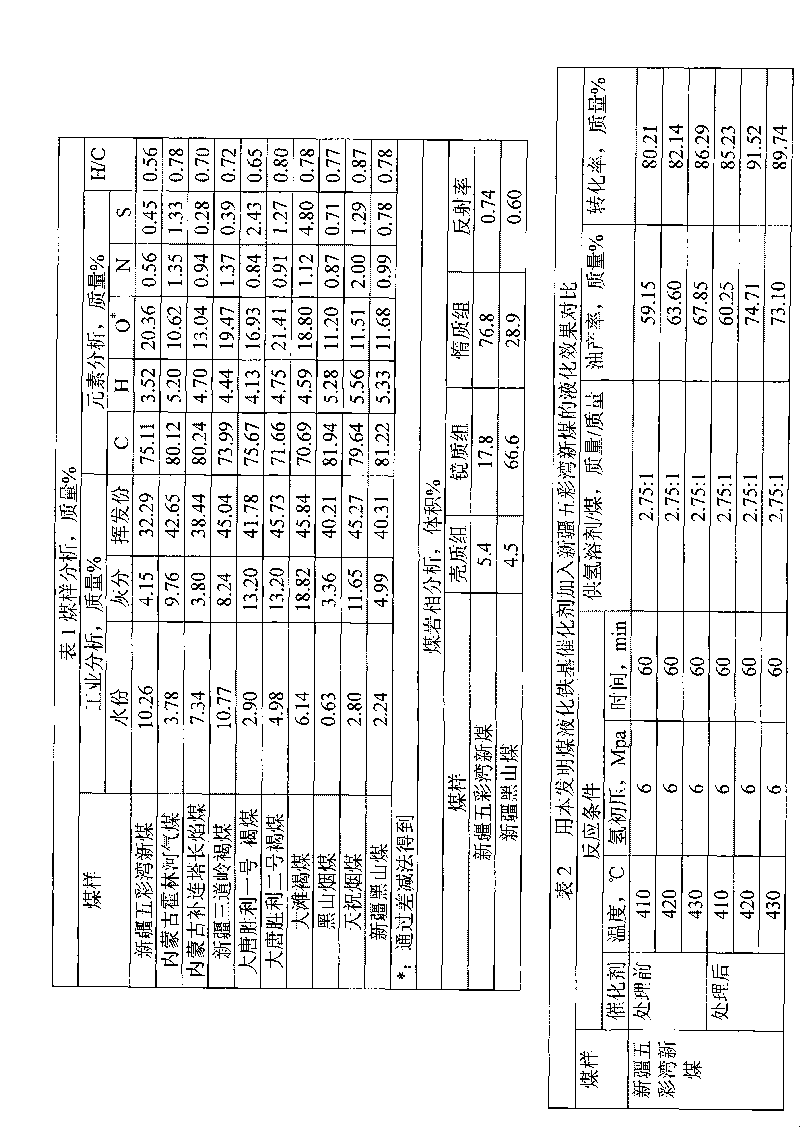

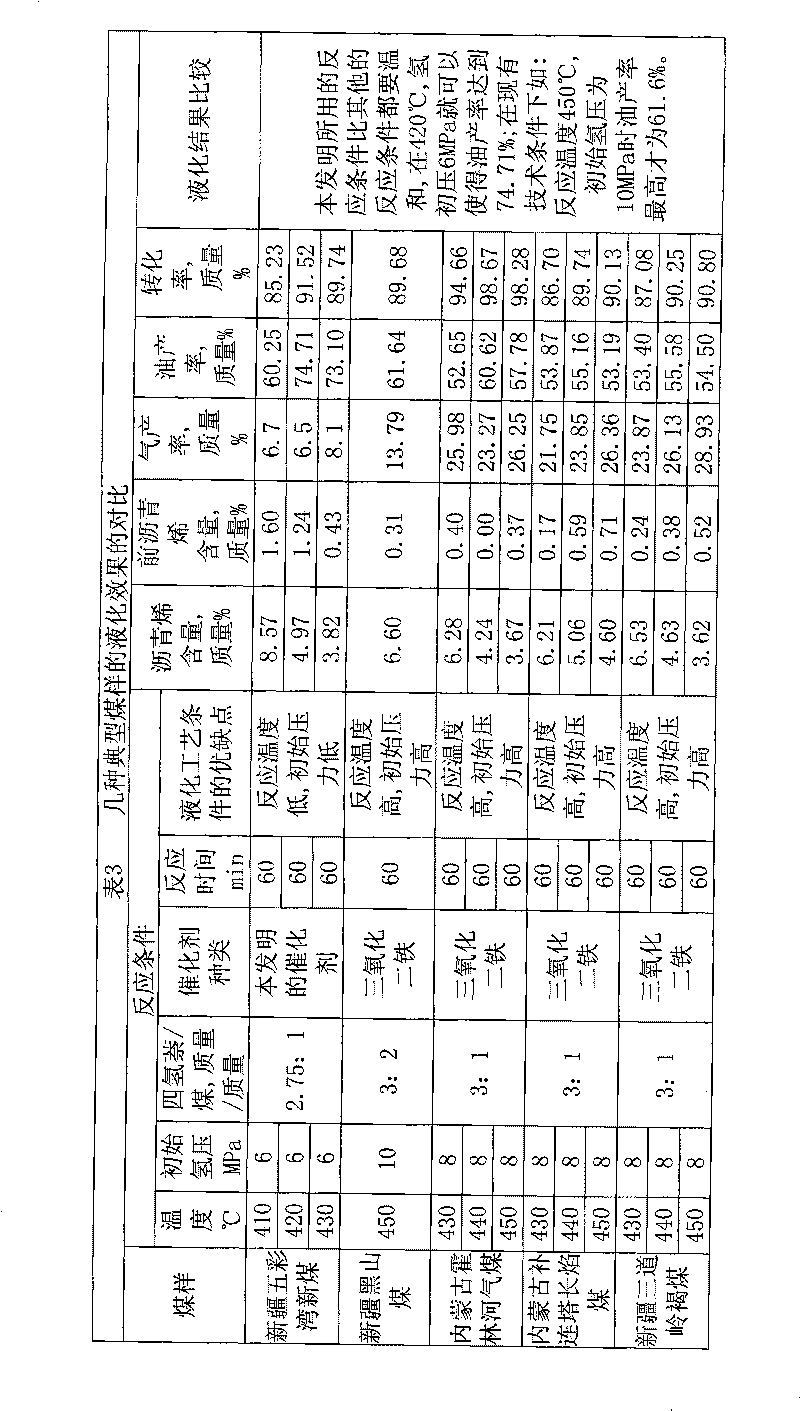

Examples

Embodiment 1

[0026] Example 1, the composition of the iron-based catalyst for coal liquefaction in molar ratio is: Fe:S:O=(63 or 64):(67 or 68):(258 or 260).

Embodiment 2

[0027] Embodiment 2, the composition of the iron-based catalyst for coal liquefaction in molar ratio is: Fe:S:O=(63-64):(67-68):(258-260).

Embodiment 3

[0028] Embodiment 3, the preparation method of this coal liquefaction iron-based catalyst is carried out as follows: the first step, takes by weighing 10 parts by weight of ferrous sulfate, 50 parts by weight or 80 parts by weight of tetrahydronaphthalene, by Fe and S mol ratio is 1: (1.7 or 3.0) Add elemental sulfur, mix ferrous sulfate, tetrahydronaphthalene, and elemental sulfur evenly, and then pour them into the autoclave; the second step is to seal the autoclave and fill it with H with a purity greater than 99%. 2And the pressure reaches (1 or 3) MPa, the stirring speed in the high-pressure reactor is (300 or 350) rad / min, and the heating rate is controlled to be (5 or 10) °C / min to the reaction temperature (300 °C or 400 °C) Keep the temperature constant for 20 minutes or 40 minutes; the third step is to cool the high-pressure reactor to room temperature, take out the reaction product and vacuum filter to obtain the filtrate and filter residue respectively, and obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com