Conductive agent dispersion liquid, electrode slurry, electrode, battery, and preparation methods thereof

A technology of electrode slurry and conductive agent, applied in battery electrodes, electrode manufacturing, conductive materials dispersed in non-conductive inorganic materials, etc., can solve problems such as uneven dispersion of conductive agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

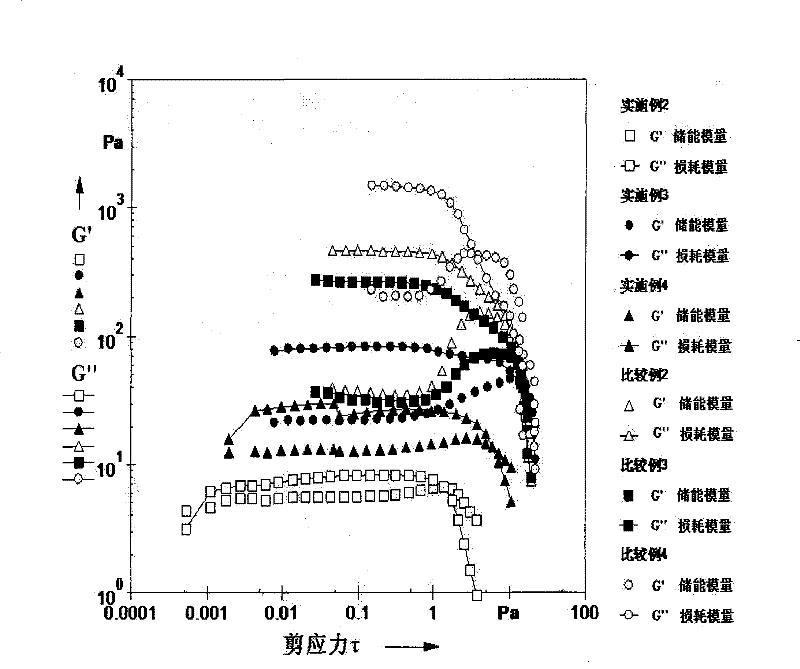

[0026] According to the preparation method of the conductive agent dispersion liquid of the present invention, wherein, the method comprises that the conductive agent is dispersed into the dispersant solution under ultrasonic vibration, the dispersant solution contains the dispersant and the first solvent, and the dispersant contains aromatic A substance that is cyclic and can be combined with the surface of the conductive agent by intermolecular van der Waals force and interplane π-π force, the solubility of the dispersant in the first solvent at 25°C is not less than 10% by weight, preferably not Less than 30% by weight, more preferably 30-80% by weight. Preferably, the weight ratio of the conductive agent, the first solvent and the dispersant is 3:(15-35):(0.6-6), preferably 3:(24-28):(2.4-3). In the conductive agent dispersion prepared according to the method, the particle diameter of the conductive agent is 2-4 microns, preferably 2-3 microns, which is far smaller than th...

Embodiment 1

[0043] This example illustrates the conductive agent dispersion and its preparation method according to the present invention.

[0044]60 grams of polyvinylpyrrolidone (purchased from Dima Technology, PVPR22K, weight-average molecular weight 22100) was dissolved in 150 grams of N, N-dimethylformamide, and then 30 grams of acetylene black (particle diameter 50 before adding Nano) is dispersed in the solution that obtains under ultrasonic vibration, uses the ultrasonic disperser of the Lucky model of Shanghai Shengyan Ultrasonic Instrument Co., Ltd., the frequency of ultrasonic is 150kHz, and the dispersion time is 90 minutes, with the QXD of Tianjin Jingke Material Testing Machine The particle size of the conductive agent in the obtained slurry measured by a model scraper fineness meter is 2-4 microns. After the obtained slurry was left to stand for 24 hours, the particle size of the conductive agent was determined to be 4-5 microns according to the above method.

Embodiment 2

[0048] This example illustrates electrode pastes and electrodes according to the invention and methods for their preparation.

[0049] First, 15 grams of polyvinylidene fluoride was dissolved in 135 grams of N-methylpyrrolidone to make a binder solution, and then 30 grams of naphthol polyoxyethylene ether (purchased from British ICI company, S-27000, weight The average molecular weight is 27000) is dissolved in 100 grams of N-methylpyrrolidone, then these two solutions are completely mixed, and then 30 grams of conductive carbon black is dispersed into the resulting mixed solution under ultrasonic vibration, using Shanghai Shengyan Ultrasonic dispersing machine of Lucky type from Ultrasonic Instrument Co., Ltd., the ultrasonic frequency is 120 kHz, and the dispersion time is 120 minutes. According to the method of Example 1, the particle size of the conductive agent in the conductive slurry is 2-3 microns. Then add 1000 g of LiCoO to this conductive agent dispersion 2 , mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com