Method for purifying microcystins MCLR through extraction and normal-pressure column chromatography

A technology of microcystin and column chromatography, which is applied in the field of analytical chemistry, can solve the problems of expensive instruments and separation columns, inability to meet the requirements of batch preparation of pure MCs, and difficulty in realizing it, and achieve good reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Take Microcystis aeruginosa (Microcystis aeruginosa) suspension 2500mL, centrifuge at 4800r / min for 10min, discard the supernatant, wash and centrifuge with ultrapure water, discard the supernatant to obtain the algae cell residue, and use Ultrasonic cell disruptor for cell disruption;

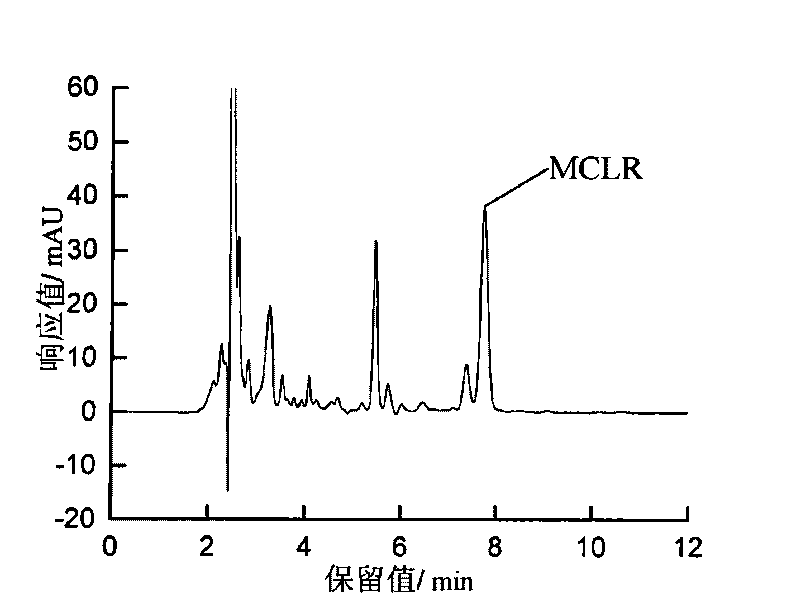

[0025] 2. Use 25mL80% methanol to shake and extract the algae cell suspension in step 1 for 4h, centrifuge at 4800r / min for 10min, and collect the supernatant (the liquid chromatogram of the crude extract is as follows: figure 1 shown);

[0026] 3. Repeat step 2 once;

[0027] 4. Combine the supernatants extracted twice in step 2 and step 3 to obtain the crude extract of MCLR, and remove methanol by rotary evaporation at 30°C;

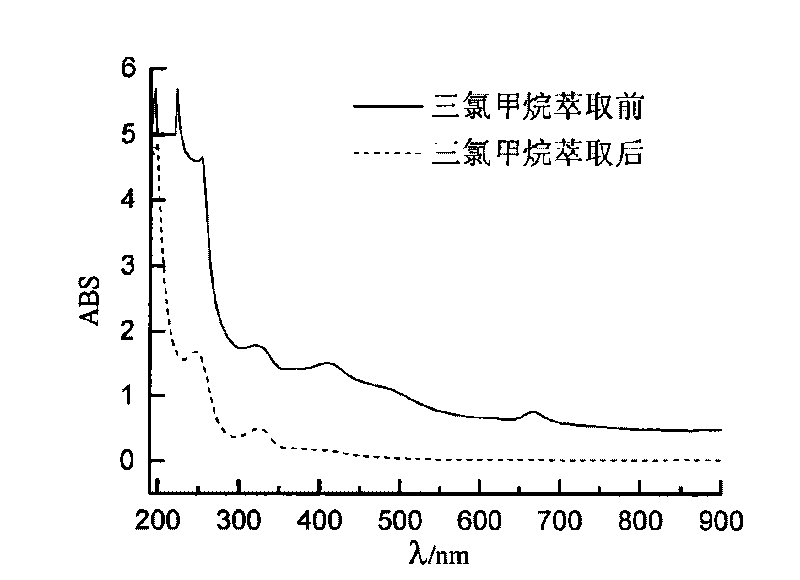

[0028] 5. Carry out liquid-liquid extraction to the aqueous solution of step 4 with chloroform, water phase: chloroform=2: 1, extract the lower layer water phase (MCLR water sample scanning picture before and after liquid-liquid extraction is as figure 2 ...

Embodiment 2-3

[0034] Except using dichloromethane and trichloromethane for liquid-liquid extraction respectively, other steps are the same as the method described in the examples to extract MCLR.

Embodiment 4

[0036] 1. Get 2500 mL of Microcystis aeruginosa suspension, centrifuge at 4800r / min for 10 min, discard the supernatant, wash and centrifuge with ultrapure water, discard the supernatant to obtain the algae cell residue, and use Repeated freeze-thaw method for cell disruption;

[0037] 2. Use 25 mL of 40% methanol to shake and extract the algae cell suspension after freezing and thawing in step 1 for 4 hours, centrifuge at 4800 r / min for 10 minutes, and collect the supernatant;

[0038] 3. Repeat step 2 once;

[0039] 4. Combine the supernatants extracted twice in step 2 and step 3 to obtain the MCLR crude extract, and remove methanol by rotary evaporation at 30°C;

[0040] 5. Carry out liquid-liquid extraction to the aqueous solution of step 4 with n-hexane, water phase: n-hexane=2:1, extract the lower aqueous phase;

[0041] 6. Repeat step 5 three times;

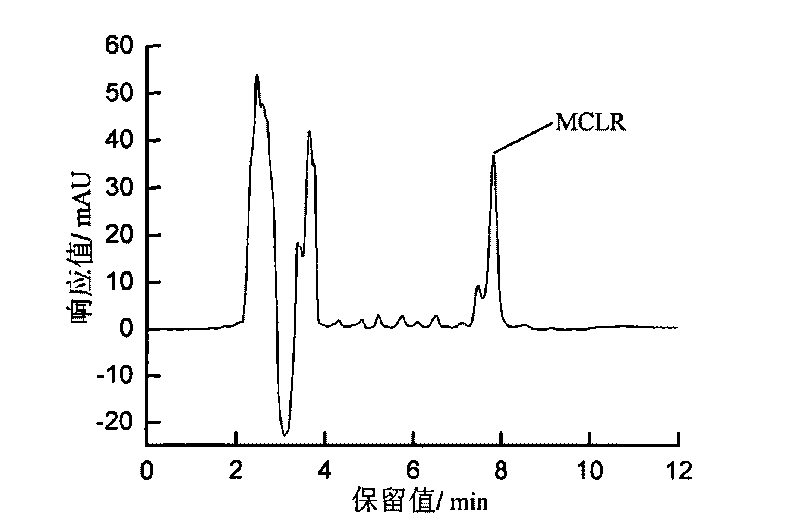

[0042] 7. Activate the C18 solid-phase extraction (SPE) cartridge (1000mg) with 10mL methanol first, then wash the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com