Processing method of coal mine water and/or coal washing waste water

A coal washing wastewater and treatment method technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of inability to remove chroma and heavy metals from additives, and unable to meet the demand for high-quality water , Tubular microfiltration membrane system is easy to be polluted and other problems, to achieve the effect of easier recovery after cleaning, ensuring high-quality water production, and improving the water quality of produced water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A coal mine water and / or coal washing wastewater mixed water in Taiyuan, Shanxi was used as the raw water for testing, and the influent water quality fluctuated, SS 1000-2500mg / L, COD 1-10mg / L, NH 3 -N value 2-6m / L, petroleum 2-3mgg / L, Fe 10-20mg / L, Mn5-10mg / L, pH 7-7.5.

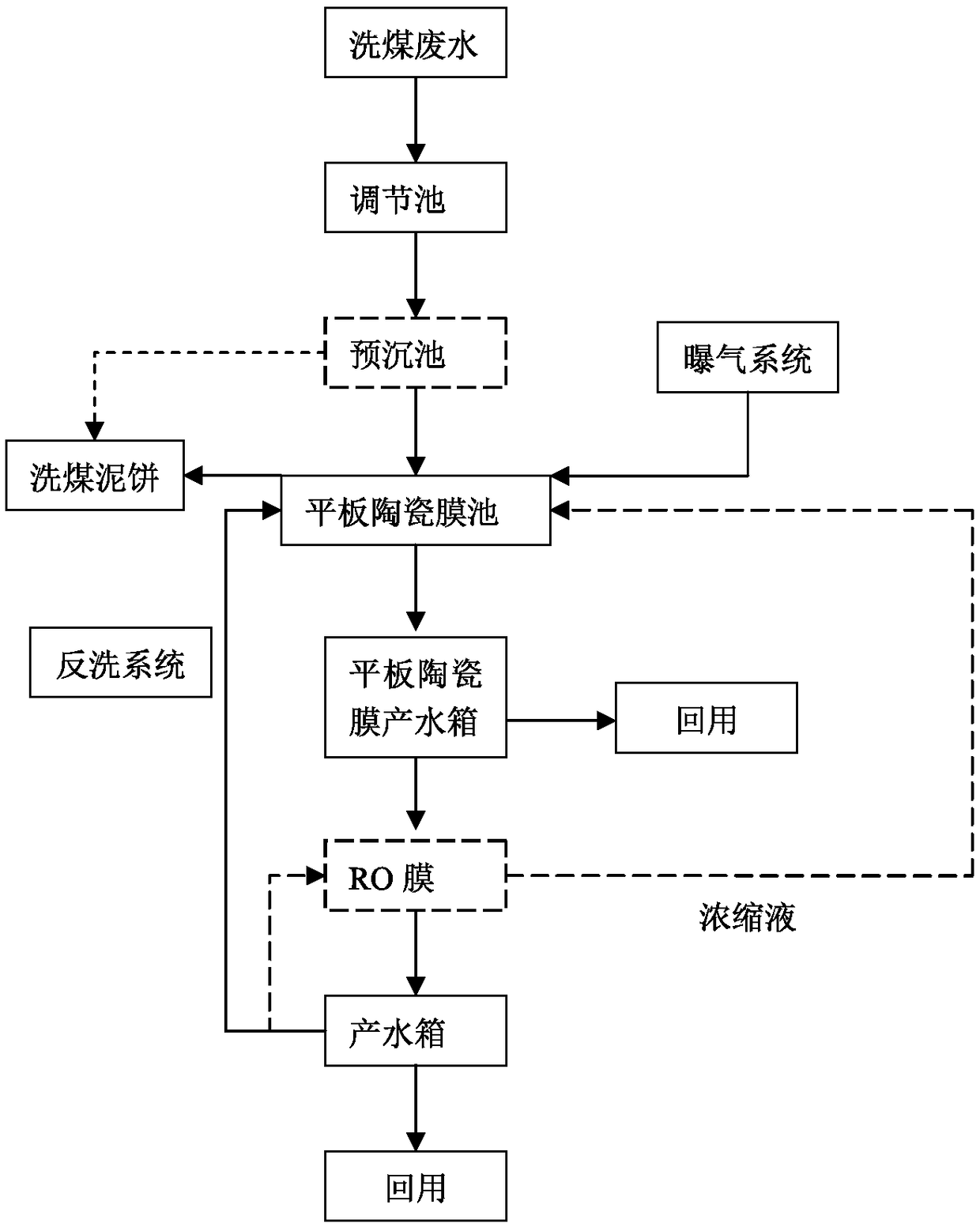

[0029] Such as figure 1 As shown, the operating parameters of this process are as follows: After the raw water passes through the regulating tank, it directly enters the flat ceramic membrane tank. The material of the flat ceramic membrane is silicon carbide, the pore size is 0.1 μm, and the membrane module area is 25m2. Every time it runs for 9 minutes, it stops for 1 minute. The suction negative pressure is -10~-20KPa, and the membrane flux is 400-500LMH. Backwash every 60min, the backwash time is 30s, the pressure is 2bar, the backwash flux is 1000LMH, after backwash, the membrane flux can be restored to 500LMH. The aeration is carried out intermittently. The aeration stops when the membrane modu...

Embodiment 2

[0032] The coal washing wastewater from a coal mine in Zhengzhou, Henan was tested as raw water. The influent water quality fluctuated, SS 6000-10000mg / L, COD 100-200mg / L, petroleum 5-8mg / L, pH 5.0-7.3.

[0033] Such as figure 1 As shown, the operating parameters of this process are as follows: After the raw water passes through the regulating tank, it enters the pre-sedimentation tank, and the hydraulic retention time is 1h.

[0034] The supernatant of the pre-sedimentation tank enters the flat ceramic membrane tank. The material of the flat ceramic membrane is alumina, the pore size is 0.2 μm, and the area of the membrane module is 50m 2 , every time it runs for 8.5 minutes, stop for 1.5 minutes, the suction negative pressure is -10 ~ -30KPa, and the membrane flux is 100-350LMH. Backwashing is performed every 30 minutes, the backwashing time is 60s, the pressure is 2bar, and the backwashing flux is 700LMH. After backwashing, the membrane flux can be restored to 350LMH. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com