Cross-pulling construction method for soft soil zone with high ground water level

A construction method and groundwater level technology, which can be used in earthwork drilling, soil protection, infrastructure engineering, etc., can solve the problems of large working well size, large impact on the surrounding environment, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and all similar methods and similar changes of the present invention should be included in the protection scope of the present invention.

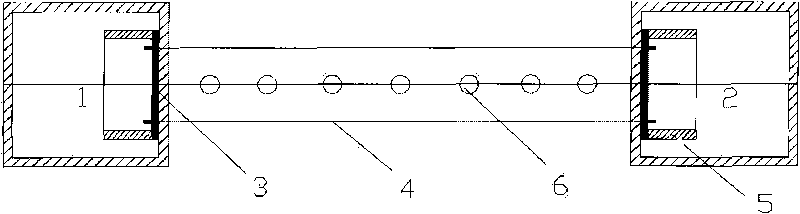

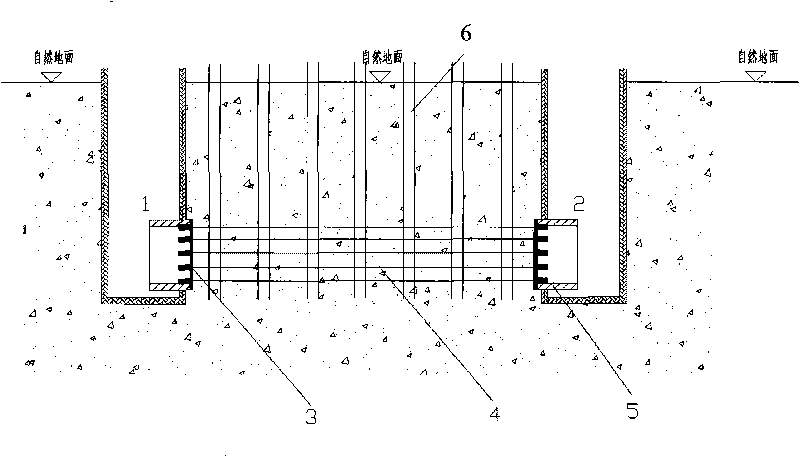

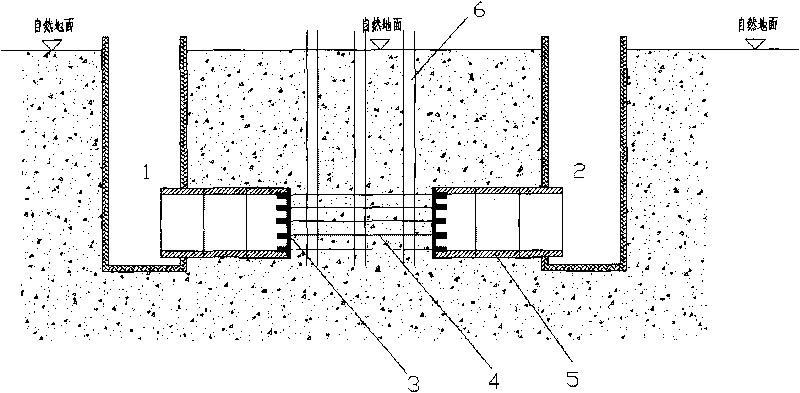

[0019] Depend on Figure 1-Figure 3 As shown, a trenchless construction method for underground pipe culverts in soft soil areas with high groundwater levels provided by the embodiments of the present invention adopts the following steps:

[0020] 1) Use the drilling method or caisson method to set up working wells 1 and 2 underground at both ends of the pipe culvert:

[0021] 2) Use horizontal directional drilling construction technology to lay steel bars or steel cables between the two working wells 1 and 2 along the project axis, and one of the starting wells is used as a working well; For the steel cable, the drilling rig is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com