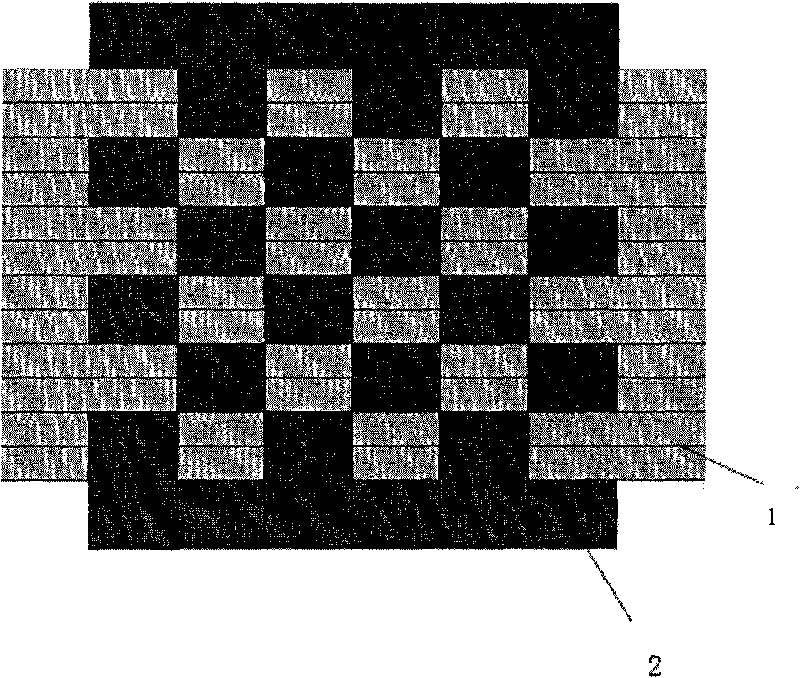

Environment-friendly polyester taslan fabric and dyeing and finishing method thereof

An environmentally friendly polyester and taslon technology, used in dyeing, fabrics, textiles, etc., can solve the problems of single color, difficult to glue fabrics, rough fabrics, etc., and achieve good appearance quality, high tear strength, and smooth fabrics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The count of DTY yarn is 500D, and the count of ATY yarn is 500D, which is woven into plain weave fabric on an air-jet loom. The weight of the obtained fabric is 160g / m 2 ±10g / m 2 Width is 160cm, and above-mentioned fabric is carried out following aftertreatment through following dyeing and finishing process:

[0049] A. Prepare:

[0050] 1) Desizing the gray cloth to be processed for subsequent use;

[0051] 2) Dissolving dyes: Put the disperse dyes into the batching container according to the ratio of gray cloth: dye = 100: 2 by weight, add water with a temperature of 90° C. and stir until the dyes are fully dissolved;

[0052] 3) Adjust the pH of the water: turn on the high temperature and high pressure overflow dyeing machine, pour clean water into the dyeing vat according to the liquor ratio gray cloth: water = 1:10, and adjust the pH value of the water to 4.5;

[0053] 4) Adjust the pH value of the super waterproof agent to 4.5-6 by adding 60g of washable supe...

Embodiment 2

[0071] The count of the DTY yarn is 200D, and the count of the ATY yarn is 200D to be woven into a twill fabric on an air-jet loom. The weight of the obtained fabric is 120g / m 2 The width of ±10 is 160cm, and the above-mentioned fabric is subjected to the following post-treatment through the following dyeing and finishing process:

[0072] A. Prepare:

[0073] 1) Desizing the gray cloth to be processed for subsequent use;

[0074] 2) Dissolving dyes: Put the disperse dyes into the batching container according to the ratio of gray cloth: dye = 100:5 by weight, add water with a temperature of 95°C and stir until the dyes are fully dissolved;

[0075] 3) Adjust the pH of the water: according to the liquor ratio gray cloth: water = 1:15, inject clear water into the dyeing vat, and adjust the pH value of the water to 4.5;

[0076] 4) Add 80g of washable super waterproof agent, 1.5g of penetrant, and 1.5g of citric acid to 1 liter of water, so that the pH value of the additive in...

Embodiment 3

[0095] The count of the DTY yarn is 250D, and the count of the ATY yarn is 250D to be woven into a twill fabric on an air-jet loom. The weight of the obtained fabric is 180g / m 2 The width of ±10 is 165cm, and the above-mentioned fabric is subjected to the following post-treatment through the following dyeing and finishing process:

[0096] A. Prepare:

[0097]1) Desizing the gray cloth to be processed for subsequent use;

[0098] 2) Dissolving dyes: Put the disperse dyes into the batching container according to the ratio of gray cloth: dye = 100: 3 by weight, add water with a temperature of 93° C. and stir until the dyes are fully dissolved;

[0099] 3) Adjust the pH of the water: according to the liquor ratio gray cloth: water = 1:12, inject clear water into the dyeing vat, and adjust the pH value of the water to 5;

[0100] 4) Add 70g of washable super waterproof agent, penetrant 1, and 1g of citric acid to 1 liter of water, so that the pH value of the additive in the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com