Thermoplastic halogen-free and low-smoke flame-retardant polyolefin sheathed plastic and preparation method and application thereof

A polyolefin sheath, low-smoke flame-retardant technology, applied in plastic/resin/wax insulators, organic insulators, conductors, etc., can solve problems such as poor fluidity, and achieve improved system fluidity, good flame retardant performance, and crack resistance. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Ethylene-vinyl acetate copolymer EVA 65 parts

[0028] Metallocene linear low density polyethylene mLLDPE 25 parts

[0029] Maleic anhydride grafted linear low density polyethylene 10 parts

[0030] Aluminum hydroxide 140 parts

[0031] Vinyltrimethoxysilane 1 part

[0032] Antioxidant 1010 0.5 parts

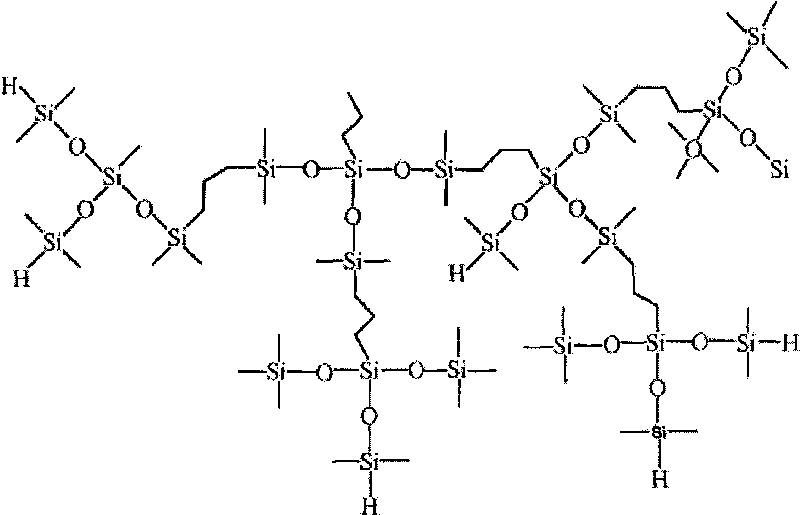

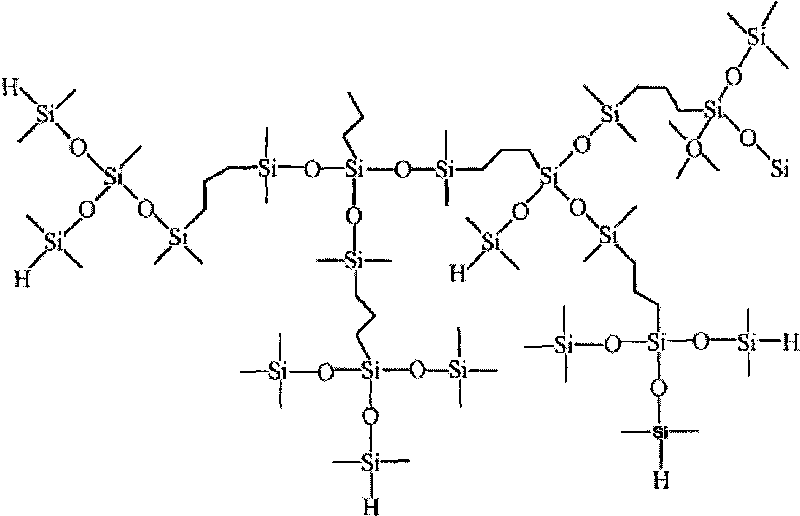

[0033] 1 part of hyperbranched polysiloxane (weight average molecular weight is 30000g / mol)

[0034] The ethylene-vinyl acetate copolymer can adopt the product of DuPont company's brand name 360; the metallocene linear low density polyethylene can adopt the product of Mitsui company's brand name SP1520;

[0035] Maleic anhydride grafted linear low-density polyethylene can use the product of Nanjing Deba Company with the brand name PE-G-4;

[0036] Vinyltrimethoxysilane can be the product of Cathay Pacific Huarong Chemical Co., Ltd. with the brand name SCA-1603; the preparation method is as follows:

[0037] (1) The above-mentioned components are banburyed in a banbu...

Embodiment 2

[0041] EVA 55 parts

[0042] mLLDPE 30 parts

[0043] Maleic anhydride grafted linear low density polyethylene 15 parts

[0044] Aluminum hydroxide 130 parts

[0045] Zinc borate 20 parts

[0046] Vinyltrimethoxysilane 2.5 parts

[0047] Antioxidant 1010 0.5 parts

[0048] 1 part of hyperbranched polysiloxane (weight average molecular weight is 40000g / mol)

[0049] The JB / T 10707-2007 standard is used for testing, and the specific performance is shown in Table 1 below. Preparation:

[0050] (1) The above-mentioned components are banburyed in a banbury mixer, the banburying time is 7min, and the temperature is 150°C;

[0051] (2) The material kneaded by the internal mixer is sheared and conveyed by the double cone, and then extruded and granulated by the single-screw extruder. : The heating / cooling section is divided into three zones, zone I 145°C±10°C, zone II 150°C±10°C, zone III 145°C±10°C; screen changing is divided into three zones, zone I 135°C±10°C, zone II 130°C ...

Embodiment 3

[0053] EVA 60 parts

[0054] Linear low density polyethylene LLDPE 12 parts

[0055] EVA grafted maleic anhydride 8 parts

[0056] Aluminum hydroxide 100 parts

[0057] Magnesium hydroxide 20 parts

[0058] Vinyltrimethoxysilane 2 parts

[0059] Antioxidant 1010 0.5 parts

[0060] Hyperbranched polysiloxane (weight average molecular weight is 30000g / mol) 2 parts

[0061] The JB / T 10707-2007 standard is used for testing, and the specific performance is shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com