Surface-functionalized molecularly imprinted polymer microsphere and preparation method thereof

A technology of surface functionalization and molecular imprinting, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of limited application, difficult surface functionalization of MIP microspheres, etc., and achieve wide application range, simple synthesis method and pure product Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

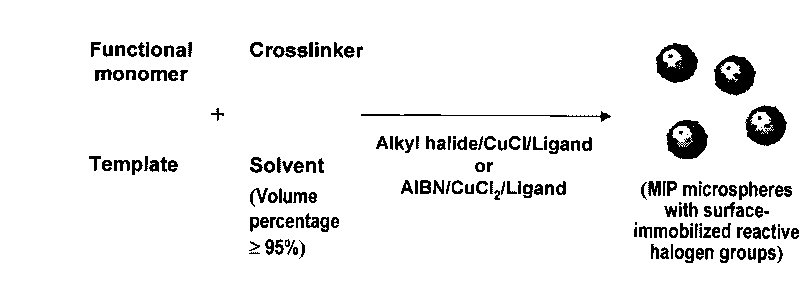

Method used

Image

Examples

example 1

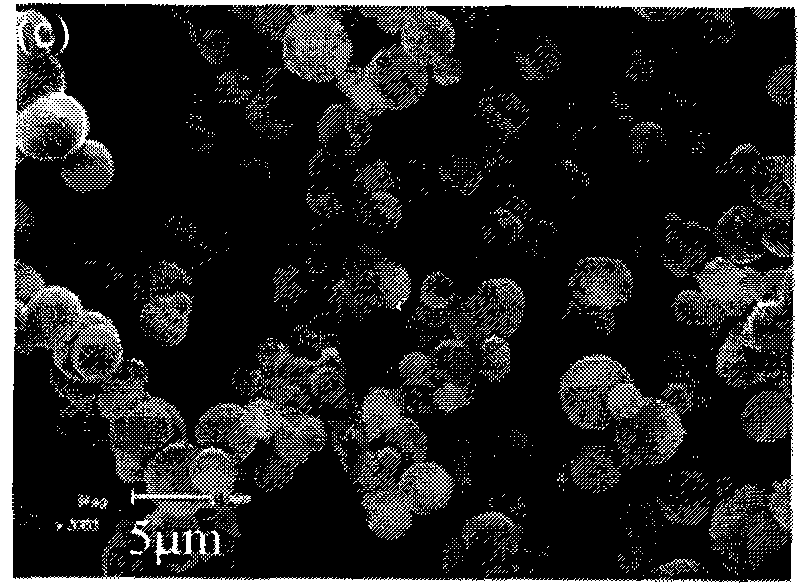

[0031] Add template molecule BPA (0.3424g), functional monomer 4-VP (160μL), cross-linking agent EGDMA (0.85mL), CuCl (5.2mg) and 30mL anhydrous acetonitrile into a 100mL round bottom flask, and the reaction solution was After deoxygenating with argon for 15 minutes, add the ligand PMDETA (22 μL), continue argon for 15 minutes, then add ethyl 2-chloropropionate (7.2 mg), seal the reaction bottle and place it in an oil bath at 60°C for reaction After 24 hours, filter, use a Soxhlet extractor to extract the obtained polymer microspheres with methanol / acetic acid (9:1v / v) for 48 hours, then extract them with acetonitrile for 24 hours, and dry them in vacuum at 40°C for 48 hours to obtain MIP microspheres. 62%.

[0032] Under the same conditions, but without adding BPA, the above reaction was carried out to prepare non-imprinted polymer (NIP) microspheres with a yield of 60%.

example 2

[0034] Template molecule BPA (0.3423g), functional monomer 4-VP (160μ), cross-linking agent EDMA (0.85mL), CuCl 2 (7.2mg) and 30mL of anhydrous acetonitrile were added to a 100mL round bottom flask. After deoxygenation by argon for 15 minutes, the ligand PMDETA (22 μL) was added, azobisisobutyronitrile (AIBN) (8.6 mg) was added after argon was continued for 15 minutes, and then the reaction bottle was sealed and placed in a 60° C. After reacting in an oil bath for 24 hours, filter, use a Soxhlet extractor to extract the obtained polymer microspheres with methanol / acetic acid (9:1 v / v) for 48 hours, then extract with acetonitrile for 24 hours, and dry in vacuum at 40°C for 48 hours to obtain MIP Microspheres, yield 85%.

[0035] Under the same conditions, but without adding BPA, the above reaction was carried out to prepare NIP microspheres with a yield of 81%.

example 3

[0037]Add template molecule 2,4-D (0.1105g), functional monomer 4-VP (0.2103g), crosslinker EGDMA (1.1893g), CuCl (0.0069g) and 30mL anhydrous acetonitrile into a 100mL round bottom flask middle. After deoxygenating the reaction solution with argon for 15 minutes, add the ligand Me 6 TREN (0.0484g), continued to pass argon for 15 minutes, then added ethyl 2-chloropropionate (9.6mg), sealed the reaction bottle, placed it in an oil bath at 60°C for 24 hours, and filtered it, then used a Soxhlet extractor to The obtained polymer microspheres were extracted with methanol / acetic acid (9:1 v / v) for 48 hours, then extracted with acetonitrile for 24 hours, and vacuum-dried at 40° C. for 48 hours to obtain MIP microspheres with a yield of 35%.

[0038] Under the same conditions, but without adding BPA, the above reaction was carried out to prepare NIP microspheres with a yield of 48%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com