Method for preparing vitamin C with low consumption

A vitamin and low-consumption technology, applied in the direction of organic chemistry and the like, can solve the problems of low crystal purity of sodium cologne, the total yield of the product needs to be further improved, etc., to shorten the production cycle, solve the problem of difficult removal, and improve the conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

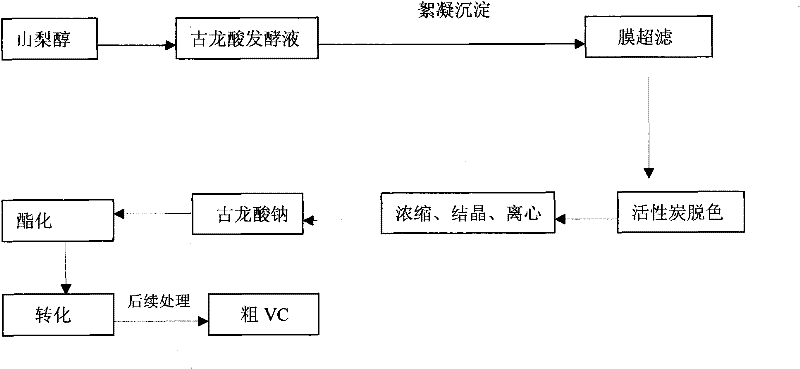

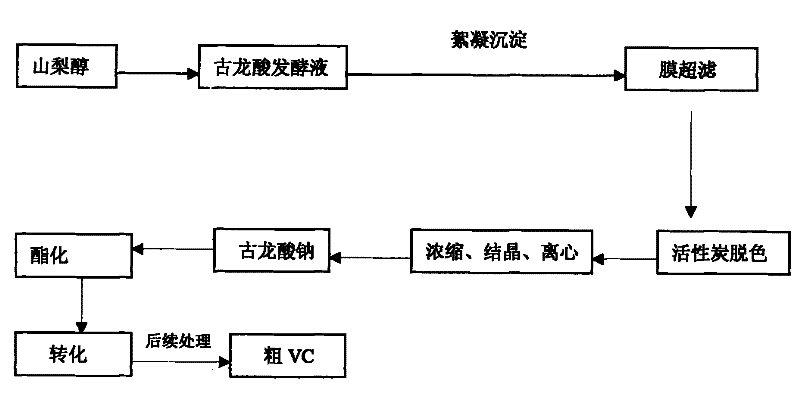

[0021] according to figure 1 Process shown:

[0022] a: Prepare vitamin C according to a conventional two-step fermentation method, ferment sorbitol to obtain gulonic acid fermented mash, and stir evenly with 1% chitosan and 1‰ polyacrylamide solution added to the fermented mash;

[0023] b: Then add 15% NaOH solution to adjust the pH of the solution to 8;

[0024] c: Pass the above-mentioned mash through a cellulose acetate membrane with a molecular weight of 50,000, pass the filtrate through an activated carbon decolorization column, and then obtain sodium guronate crystals according to the usual methods of concentration, crystallization and centrifugation;

[0025] d: the esterification reaction carried out by sodium guronate crystals with methanol and concentrated sulfuric acid, its dosage ratio is: sodium guronate crystals: methyl alcohol=1kg: 5L; sodium guronate: H 2 SO 4 (98%) is 1Kg:0.13L, the reaction temperature is 66-67°C, the reaction time is 4 hours, and the pH...

Embodiment 2

[0030] a: Prepare vitamin C according to a conventional two-step fermentation method, ferment sorbitol to obtain gulonic acid fermentation mash, and stir the 2% chitosan solution added in the fermentation mash evenly;

[0031] b: Then add 12% NaOH solution to adjust the pH of the solution to 10;

[0032] c: Pass the above-mentioned mash through a cellulose acetate membrane with a molecular weight of 30,000, pass the filtrate through an activated carbon decolorization column, and then obtain sodium guronate crystals according to the usual methods of concentration, crystallization and centrifugation;

[0033] d: the esterification reaction carried out by sodium guronate crystals with methanol and concentrated sulfuric acid, its dosage ratio is: sodium guronate crystals: methanol=1kg: 3L; sodium guronate: H 2 SO 4 (98%) is 1Kg:0.19L, the reaction temperature is 66°C, the reaction time is 4 hours, and the pH is controlled at 1.9.

[0034] e: The above reaction solution is added ...

Embodiment 3

[0038] Prepare vitamin C according to the conventional two-step fermentation method, ferment corn to obtain gulong acid fermentation mash, add chitosan solution in the fermentation mash according to the mass ratio of chitosan and fermentation mash to 2%, and then add the chitosan solution according to the mass ratio to 1‰, add polyacrylamide and stir evenly, then add 10% NaOH to adjust the pH of the solution to 10; decolorize the filtrate from membrane filtration to obtain sodium guronate crystals, and carry out esterification reaction, first add 2500ml of methanol, then add 600g of sodium guronate , finally slowly add 84.5ml of concentrated sulfuric acid, control PH = 2.1, esterify for 4.5 hours, cool down, slowly add NaHCO 3 158g reacted for 2 hours, then added Na 2 CO 3 React 80g for 2 hours, control PH = 7, acidify directly after the reaction, add an appropriate amount of water to make the methanol concentration of the system 82% to 84%, slowly add an appropriate amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com