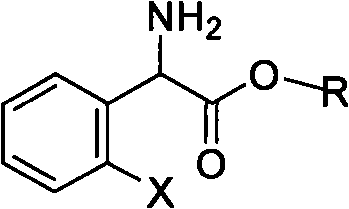

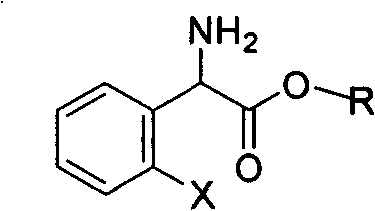

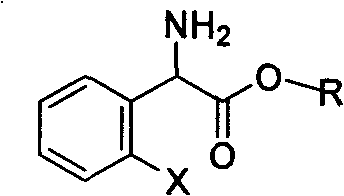

Synthesis of clopidogrel impurity intermediate

A diastereomer and process technology, which is applied in the field of important intermediates for the preparation of clopidogrel, a highly active anti-platelet aggregation drug, can solve the problems of potential danger, long reaction time, large loss of raw materials, etc., and can achieve the operation cycle Short, easy to operate, good for yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0037] Add D-(-)-tartaric acid (6.6 g, 0.044 mol) and anhydrous methanol (64 ml) into a 100 ml three-necked flask, and stir at room temperature until they are completely dissolved. A mixed solution of 2-chlorophenylglycine methyl ester (8.0 g, 0.04 mol) and acetone (16 ml) was added dropwise into the reactor, and solids were precipitated during the dropwise addition, which took about 1 hour. After the dropwise addition, react at 28-32°C for 15-20 hours. After the reaction was cooled, stirring was continued for one hour. Suction filtration and filter cake drying to obtain dry solid (R)-(-)-2-chlorophenylglycine methyl ester tartrate, yield 89%, melting point 164-166°C (document: 163-167°C) optical rotation [α] D -86 0 (C=1, CH 3 Oh)

specific Embodiment 2

[0038] Add D-(-)-tartaric acid (6.6 g, 0.044 mol) and anhydrous methanol (64 ml) into a 100 ml three-necked flask, and stir at room temperature until they are completely dissolved. After adding catalytic amount of acetophenone, the mixed solution of 2-chlorophenylglycine methyl ester (8.0g, 0.04mol) and acetone (16ml) is added dropwise in the reactor, there is solid to separate out in the process of dropping, about 1 Hour. After the dropwise addition, react at 28-32°C for 5-6 hours. After the reaction was cooled, stirring was continued for 1 hour. Suction filtration and drying of the filter cake gave dry solid (R)-(-)-2-chlorophenylglycine methyl ester tartrate. Yield 92%, melting point 164-166°C (document: 163-167°C) optical rotation [α] D -88 0 (C=1, CH 3 OH).

specific Embodiment 3

[0039]Add D-(-)-tartaric acid (6.6 g, 0.044 mol) and anhydrous methanol (64 ml) into a 100 ml three-necked flask, and stir at room temperature until they are completely dissolved. After adding a catalytic amount of formaldehyde, a mixed solution of 2-chlorophenylglycine methyl ester (8.0g, 0.04mol) and acetone (16ml) was added dropwise into the reactor, and solids were precipitated during the dropwise addition, which took about one hour . After the dropwise addition, react at 28-32° C. for 10-20 hours. After the reaction was cooled, stirring was continued for one hour. Suction filtration and drying of the filter cake gave dry solid (R)-(-)-2-chlorophenylglycine methyl ester tartrate. Yield 85%, melting point 164-166°C (document: 163-167°C) optical rotation [α] D -88 0 (C=1, CH 3 OH).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com