Method and apparatus for capturing CO2 in flue gas by utilizing three-phase circulating fluidized bed and ammonia

A fluidized bed and phase circulation technology, applied in chemical instruments and methods, separation methods, chemical separation, etc., can solve the problems of corrosion resistance and mechanical strength, uneven gas-liquid distribution, and high cost of packed towers. Effects of high decarbonization efficiency, improved availability, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

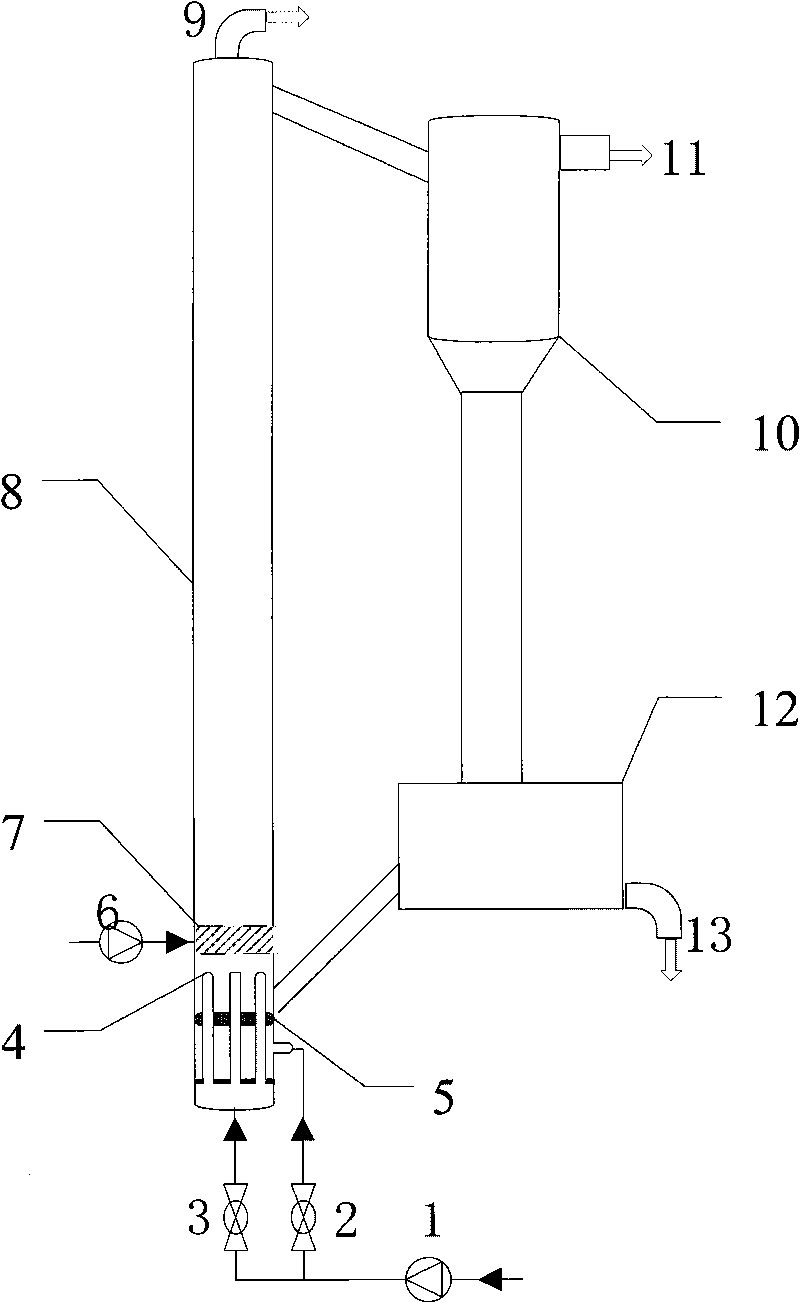

[0024] The flue gas of the power plant passes through the electrostatic precipitator or bag filter, and contains a certain mass fraction of fine fly ash. The flue gas temperature is 120°C. The actual flue gas emission is calculated according to the coal input amount and the excess air coefficient, and the fan 6 is adjusted according to the actual flue gas flow rate to ensure that the cross-sectional gas velocity of the riser is 0.1m / s, and the flue gas enters the riser from the side through the gas distributor 7; Ammonia water with a mass concentration of 25% passes through the booster pump 1 and is divided into two paths, one as the main flow and the other as the auxiliary flow; the main flow enters the riser 8 from the bottom of the riser through the main flow distributor 4, and passes Adjust the booster pump 1 and the main water flow throttle valve 3 to ensure the flow rate of the main water flow is 0.5m / s; the gas-liquid phase of the riser is in a continuous bubbling state,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com