Method for manufacturing laser diode having coaxial long linear structure and luminous device thereof

A technology of laser diodes and linear structures, applied in lasers, phonon exciters, optical waveguides, etc., can solve the problems of laser diodes, inconvenience, and increased manufacturing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Manufacturing method of coaxial long line laser diode

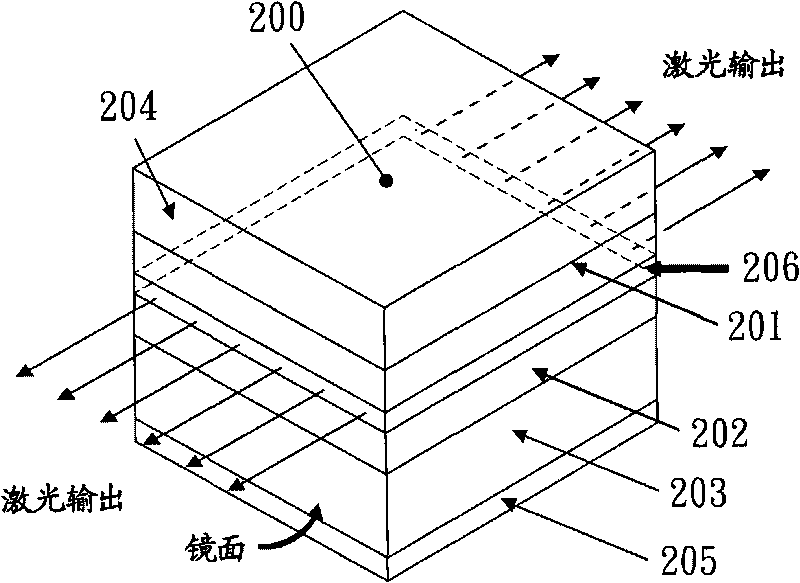

[0087] This embodiment is based on Figure 7B The VLSED method shown is the vertical large-scale synchronous long linear epitaxial deposition method. Using this VLSED method, ten coaxial long linear double heterostructure laser crystal rods each 1 meter long can be deposited simultaneously on one machine, and then each The laser ingot made by branch is cut into sections, and then it can be made into Figure 8A coaxial long line laser diode. The manufacturing process begins with an axial base rod (Subrod) 606 each 1 meter long and 2 mm in outer diameter installed in ten quartz tubes, such as Figure 7A shown. see Figure 12A As shown, it is a schematic diagram of the axial pre-engraved Bragg grating base rod manufactured by the VGF crystal growth method. The axial base rod is made of Figure 12A The vertical gradient cooling VGF crystal growth method is shown. This axis-based rod vertical gradient (Vertical Gr...

Embodiment 2

[0097] Solid-state white light illumination combined with coaxial long-line laser diode and coaxial light-emitting fiber

[0098] The combination of three coaxial long-line red, green and blue laser diodes made in Example 1 and three coaxial light-emitting optical fibers can synthesize a white light solid-state lighting device. see Figure 11 As shown, it is a top view of three cores of a three-color light-emitting optical fiber to form a bundle to synthesize white light. 1101 is a red light-emitting fiber, 1102 is a green light-emitting fiber, 1103 is a blue light-emitting fiber, and 1104 is each irradiation point of three-color synthetic white light. Alternatively, a blue coaxial long-line laser and a yellow coaxial long-line laser can be respectively injected into two twisted coaxial light-emitting optical fibers to form a solid-state lighting device that emits complementary white light.

Embodiment 3

[0100] Coaxial long-line laser diode and coaxial light-emitting optical fiber cooperate with fluorescent powder to form a white light lighting device

[0101] A combination of coaxial long-line laser diodes injected into coaxial light-emitting fibers, which are packed into fluorescent tubes to form a white light lighting device, please refer to Figure 13 As shown, it is a schematic diagram of a coaxial long-line laser and a coaxial light-emitting fiber loaded into a fluorescent tube. 1301 is the blue light-emitting optical fiber, 1302 is the second preparatory light-emitting optical fiber (the purpose is an adjustable light color structure), 1303 is the inner coating of the yellow phosphor, and 1304 is the external power supply seat of the coaxial long-line laser diode. Coaxial long-line laser diode combined light-emitting fiber is coated with phosphor tube, and the method of synthesizing white light is as the existing conventional long tube-shaped fluorescent lamp using phos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com