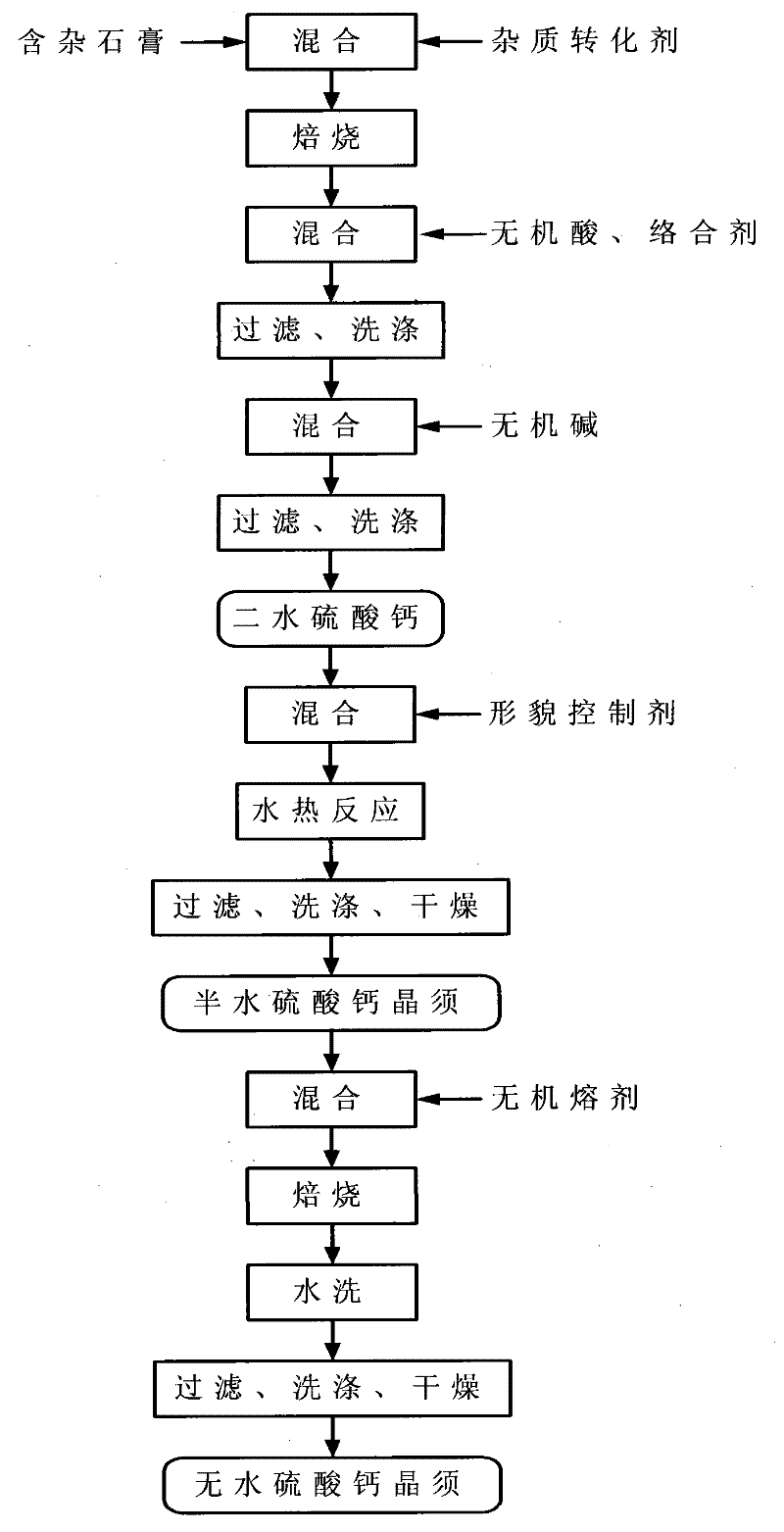

Method for preparing calcium sulfate crystal whiskers by using impurity-containing gypsum as raw material

A technology of calcium sulfate whisker and gypsum, which is applied in chemical instruments and methods, calcium/strontium/barium sulfate, single crystal growth, etc., can solve the problem that it is difficult to prepare calcium sulfate whiskers and calcium sulfate dihydrate. Dissolution and transformation, comprehensive utilization rate of less than 10% and other problems, to achieve the effect of high product added value, regular morphology, and large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Take by weighing natural gypsum (main composition: CaSO 4 2H 2 O: 99wt%, SiO 2 : 0.5wt%, Al 2 o 3 : 0, Fe 2 o 3 :0, MgO:0, P 2 o 5 :0,F:0,CO 3 : 0) 100g, sodium chloride 1g, the two are mixed and roasted at 300°C for 1h to obtain calcined sand. Add calcined sand to an aqueous solution containing 0.1mol / L hydrochloric acid and 0.1mol / L ethylenediaminetetraacetic acid to prepare a suspension with a solid content of 1 wt%, and react for 5 hours at 20°C with stirring (500 rpm) After filtering and washing the above slurry, add a sodium hydroxide solution with a concentration of 0.1mol / L to make a suspension with a solid content rate of 1wt%, react at 20°C for 5h under stirring (500 rpm), and filter 1. After washing, the calcium sulfate dihydrate precursor is obtained.

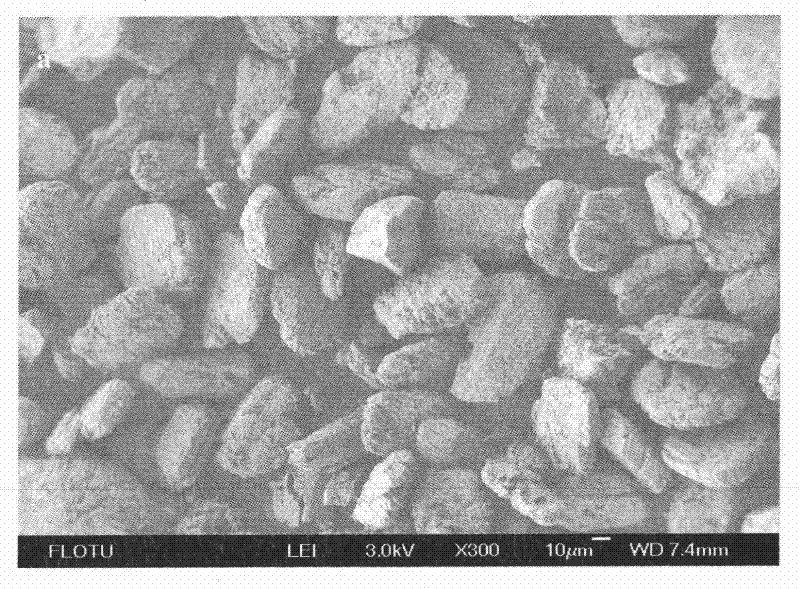

[0046] Put the calcium sulfate dihydrate precursor into the autoclave, add 0.005mol / L sodium chloride solution to adjust the solid content to 0.1wt%, and perform a hydrothermal reaction at 100°C for...

Embodiment 2

[0048] Take by weighing phosphogypsum (main composition: CaSO 4 2H 2 O: 70wt%, SiO 2 : 2wt%, Al 2 o 3 : 5wt%, Fe 2 o 3 : 5wt%, P 2 o 5 : 5wt%, F: 2wt%, CO 3 : 2wt%) 100g, potassium chloride 20g, after the two are mixed, roast at 800°C for 5h to obtain calcined sand. Add calcined sand to an aqueous solution containing 5mol / L hydrochloric acid and 0.5mol / L succinic acid to make a suspension with a solid content of 30wt%, and react for 1 hour at 100°C under stirring (50 rpm); After the slurry is filtered and washed, a potassium hydroxide solution with a concentration of 5 mol / L is added to make a suspension with a solid content rate of 30 wt%, and reacted at 100° C. for 1 hour under stirring (50 rpm) conditions, filtered and washed to obtain Precursor of calcium sulfate dihydrate.

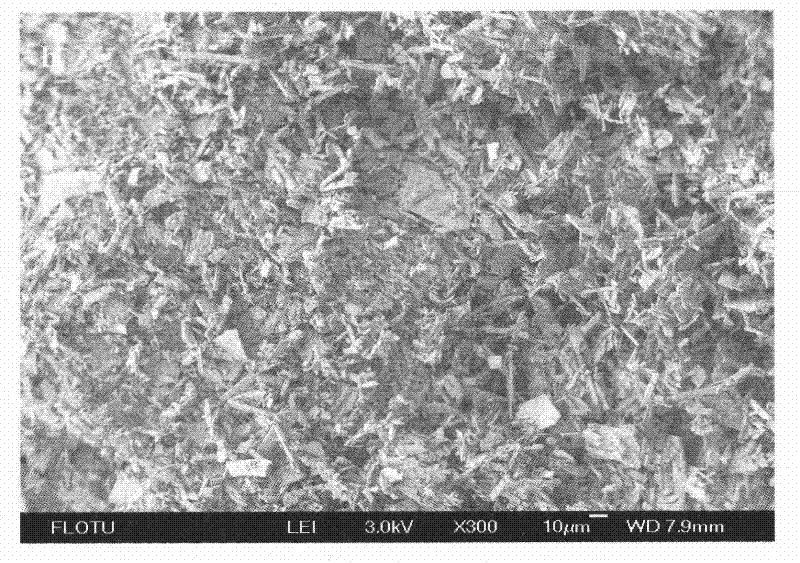

[0049] Put the precursor of calcium sulfate dihydrate into a high-pressure reactor, add 5mol / L potassium chloride solution to adjust the solid content to 25wt%, react hydrothermally at 250°C...

Embodiment 3

[0051] Weigh desulfurized gypsum (main composition: CaSO 4 2H 2 O: 80wt%, SiO 2 : 2.5wt%, Al 2 o 3 : 2.5wt%, Fe 2 o 3 : 2wt%, CO 3 : 10wt%) 100g, ammonium chloride 10g, the two are mixed and roasted at 500°C for 2.5h to obtain calcined sand. Add calcined sand to an aqueous solution containing 2mol / L hydrochloric acid and 1mol / L citric acid to make a suspension with a solid content of 10wt%, and react for 2 hours at 40°C under stirring (250 rpm); filter the above slurry After washing, add ammonia solution with a concentration of 2.5mol / L to make a suspension with a solid content of 10wt%, react at 40°C and stir (250 rpm) for 2.5h, filter and wash to obtain dihydrate Calcium sulfate precursor.

[0052] Put the calcium sulfate dihydrate precursor into the autoclave, add 2mol / L sodium sulfate solution to adjust the solid content to 5wt%, react hydrothermally at 150°C for 2h under stirring (250 rpm), cool, filter, and wash , Drying (105°C, 4h), the intermediate product of ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com