Converter fume high-temperature bag dust removal and recycling and secondary steam recycling system

A secondary recovery, bag-type dust removal technology, applied in furnaces, furnace components, manufacturing converters, etc., can solve the problem of not recovering secondary steam, and achieve the effects of saving primary investment costs, high dust removal efficiency, and reduced specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

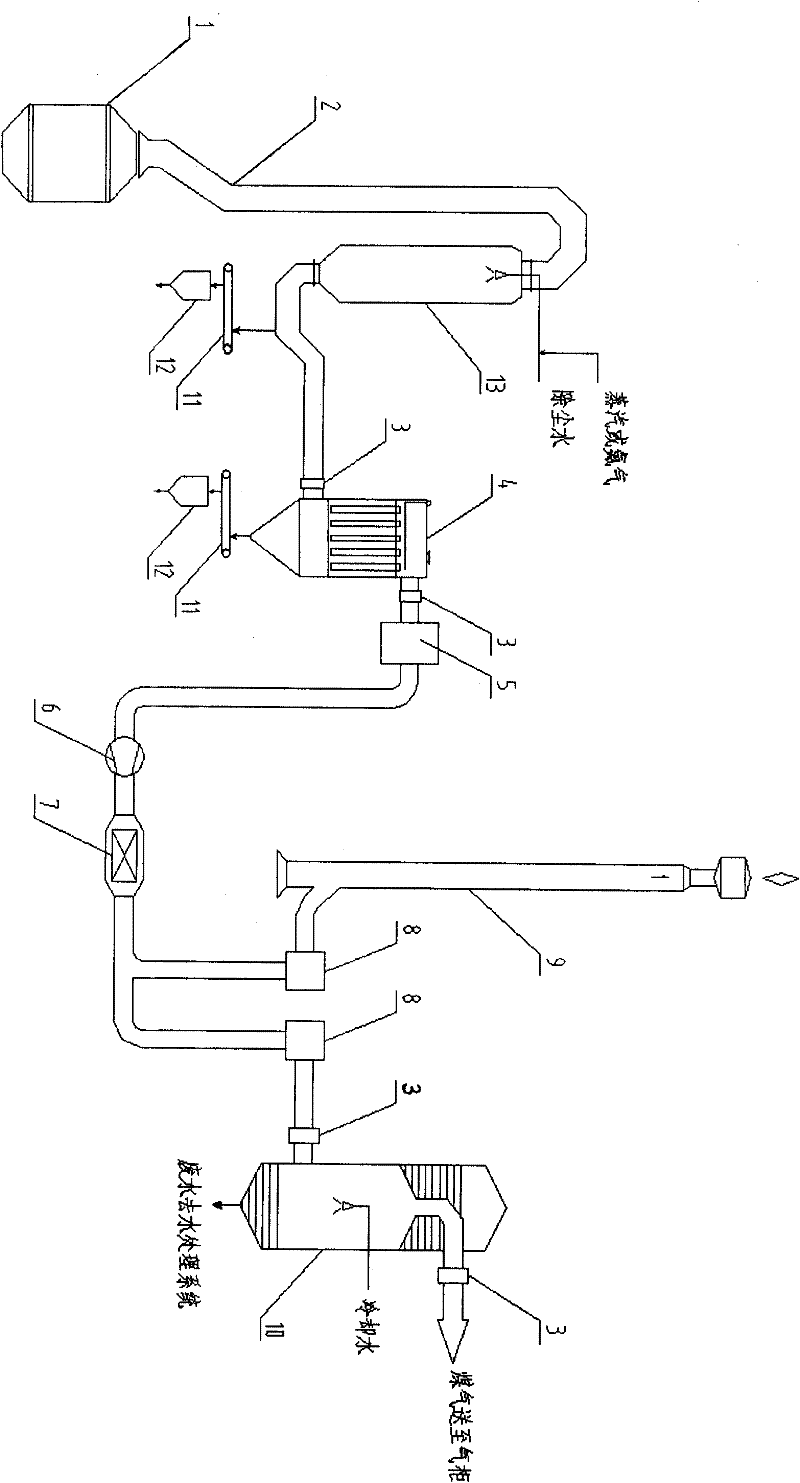

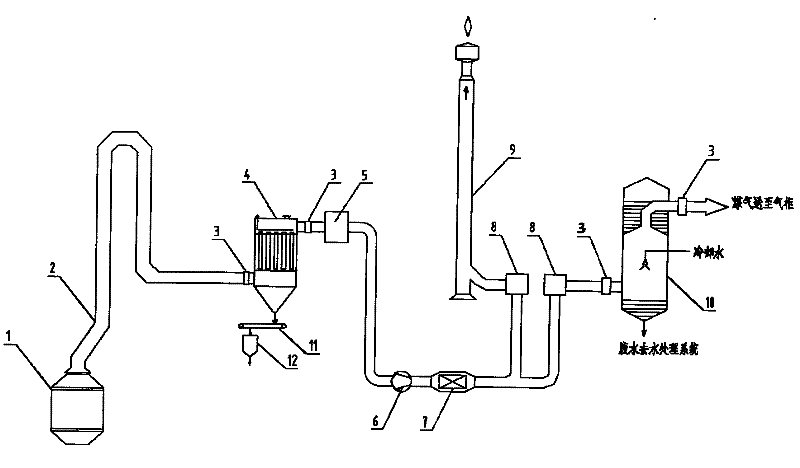

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] see figure 1 , the present invention is a high-temperature bag-type dedusting and recovery system for converter flue gas and steam secondary recovery system, which mainly consists of a converter 1, a vaporization flue 2 and a cooling device, a high-temperature bag filter 4, a waste heat boiler 5, and a speed-regulating fan 6 , Switching valve station 8, release chimney 9, gas cooling tower 10, several glasses valves 3, ash conveying device 11, ash storage bin 12 and automatic control system, etc., all parts and devices are connected through pipelines.

[0034] The high-temperature bag filter 4 purifies the flue gas with a temperature of 800°C or below at the outlet of the vaporization flue 2, and a waste heat boiler 5 is installed at the outlet of the high-temperature bag filter 4 for secondary steam recovery. The waste heat boiler 5 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com