Wear resistant self-lubricating coating for brush type sealed track and preparation method thereof

A self-lubricating coating and brush-type sealing technology, which is applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of PbO solid lubricant application limitations, reduce friction coefficient, improve surface performance, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Prepare a wear-resistant self-lubricating coating on a brush-type sealed raceway, the method is as follows: take WC-12Co powder and Ag powder as raw materials, and the weight of Ag powder in the raw materials used accounts for 10% of the total weight of WC-12Co powder and Ag powder. The raw material is made into composite powder by spray granulation process, and the composite powder with a particle size of 15-45 μm is screened out, and sprayed on the surface of the brush-type sealing runway by supersonic flame spraying, then a wear-resistant self- Lubricant coating.

[0017] In the wear-resistant self-lubricating coating for brush seal raceways prepared by the above method, the components and their weight percentages are as follows: Ag: 9.8%, Co: 10.8%, C: 4.5%, W: 74.9%.

[0018] The bonding strength of the wear-resistant self-lubricating coating prepared in this example and the substrate is greater than 60MPa, and the average value of microhardness HV 0.3 The coeffic...

Embodiment 2

[0020] Prepare a wear-resistant self-lubricating coating on a brush-type sealed track, the method is as follows: take WC-12Co powder and Ag powder as raw materials, and the weight of Ag powder in the raw materials used accounts for 15% of the total weight of WC-12Co powder and Ag powder. The raw material is made into composite powder by spray granulation process, and the composite powder with a particle size of 15-45 μm is screened out, and sprayed on the surface of the brush-type sealing runway by supersonic flame spraying, then a wear-resistant self- Lubricant coating.

[0021] In the wear-resistant self-lubricating coating for brush seal raceways prepared by the above method, the components and their weight percentages are as follows: Ag: 15.3%, Co: 10.2%, C: 4.2%, W: 70.3%.

[0022] The wear-resistant self-lubricating coating prepared in this example has a bonding strength greater than 60 MPa and an average value of microhardness HV 0.3 The coefficient of friction of the ...

Embodiment 3

[0024] The wear-resistant self-lubricating coating is prepared on the brush-type sealed track, and the method is as follows: take WC-12Co powder and Ag powder as raw materials, and the Ag powder weight accounts for 18% of the total weight of WC-12Co powder and Ag powder in the raw materials used, and the above-mentioned The raw material is made into composite powder by spray granulation process, and the composite powder with a particle size of 15-45 μm is screened out, and sprayed on the surface of the brush-type sealing runway by supersonic flame spraying, then a wear-resistant self- Lubricant coating.

[0025] In the wear-resistant self-lubricating coating for brush seal raceways prepared by the above method, the components and their weight percentages are as follows: Ag: 17.9%, Co: 9.8%, C: 4.1%, W: 68.2%.

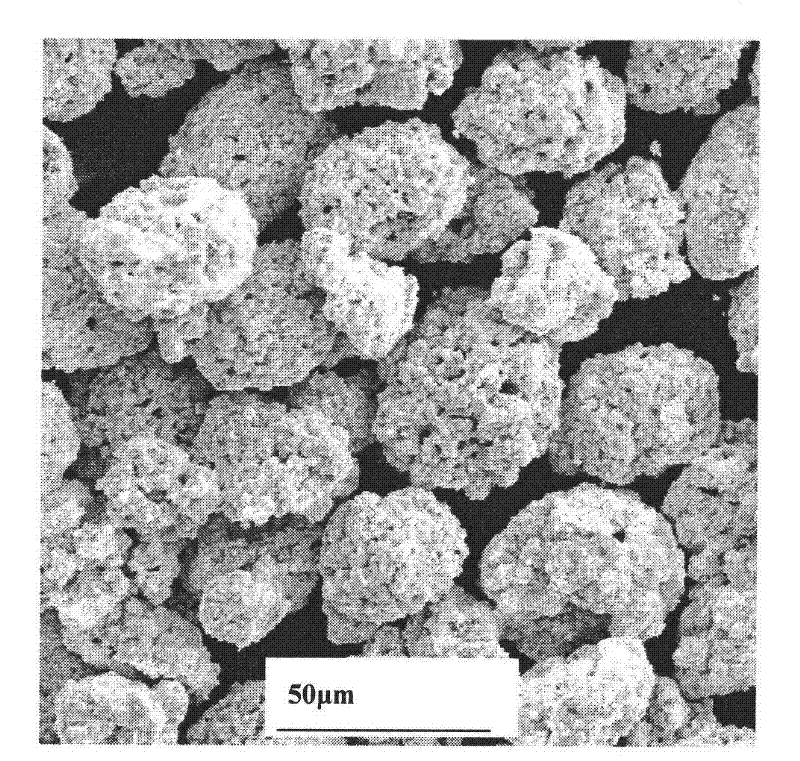

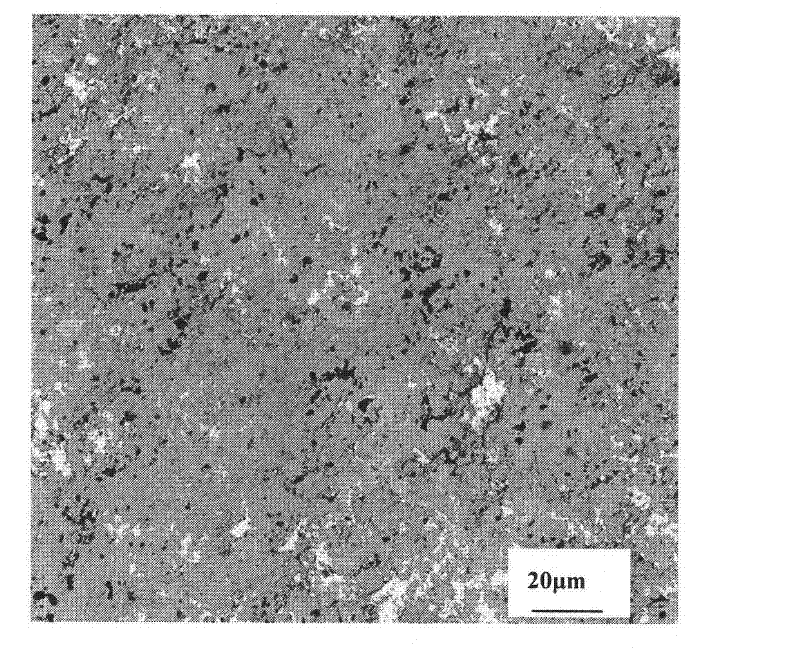

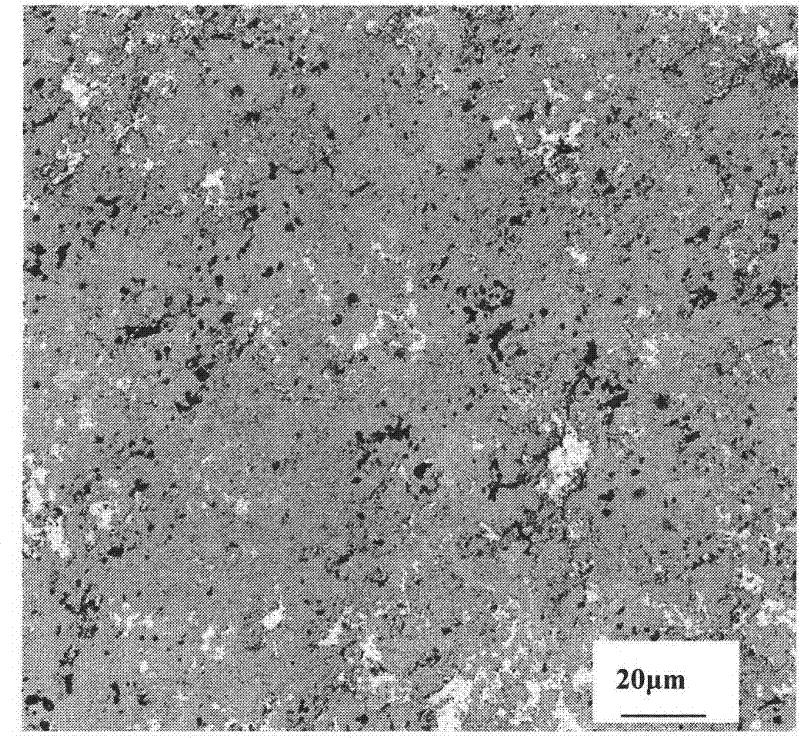

[0026] The microscopic morphology of the thermal spraying composite powder of this embodiment is as follows: figure 1 As can be seen from the figure, the microscopic m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com