Foamable flame resistance polyethylene composite material and preparation method thereof

A technology of flame-retardant polyethylene and composite materials, applied in the field of foamed flame-retardant polyethylene composite materials and its preparation, can solve the problems of small expansion ratio, high flame retardant addition, high cost, etc., and achieve basic mechanical properties Excellent, simple preparation process, excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

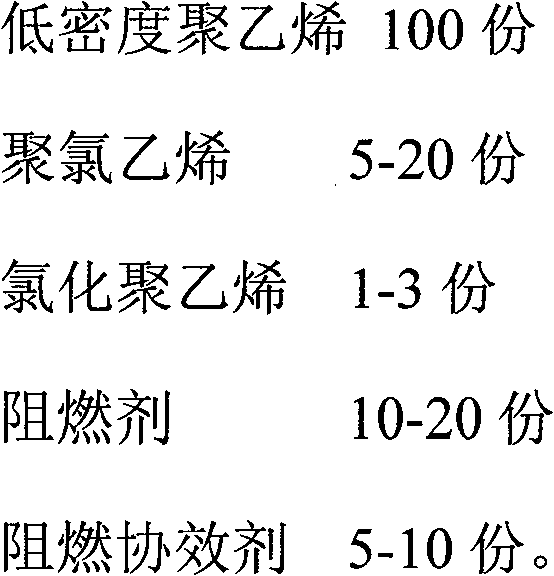

Method used

Image

Examples

Embodiment 1

[0039] Weigh 100 parts of low-density polyethylene with a melting index of 4g / 10min, 10 parts of polyvinyl chloride with a melting index of 10g / 10min, 2 parts of chlorinated polyethylene with a mass content of chlorine element of 40%, 10 parts of decabromodiphenylethylene alkane, 5 parts of antimony trioxide, 0.1 part of flame retardant synergist 2,3-dimethyl-2,3-diphenylbutane, 0.5 part of heat stabilizer calcium stearate, 1 part of plasticizer Dibutyl phthalate, 0.5 part of main antioxidant tetrakis [methyl-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 0.5 part of auxiliary antioxidant tris(2 , 4-di-tert-butylphenyl) ester, 0.1 part of light stabilizer 2-(2'-hydroxy-3'-tert-butyl-5'-methyl)-5-chlorobenzotriazole and lubricant 0.5 parts of erucamide, after fully mixing by stirring, add the twin-screw extruder whose length-to-diameter ratio L / D is 48:1, and the screw diameter is 42mm, and the feeding speed is 300g / min; the control screw speed is 500...

Embodiment 2

[0041] Weigh 100 parts of low-density polyethylene with a melting index of 10g / 10min, 20 parts of polyvinyl chloride with a melting index of 20g / 10min, 3 parts of chlorinated polyethylene with a mass content of chlorine element of 80%, 10 parts of decabromodiphenyl ether , 5 parts of antimony trioxide, 0.5 parts of flame retardant synergist 2,3-dimethyl-2,3-diphenylbutane, 0.5 parts of heat stabilizer lead stearate, 2 parts of plasticizer phthalate Dibutyl diformate, 0.5 parts of primary antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate, 0.5 parts of secondary antioxidant pentaerythritol bisphosphite bis(octadecyl) Alcohol) ester, 1 part of light stabilizer 2-(2'-hydroxyl-3', 5'-di-tert-butylphenyl)-5-chlorobenzotriazole, 1 part of light stabilizer succinic acid and 4 -Polymer of hydroxy-2,2,6,6-tetramethyl-1-piperidinol and 0.5 part of lubricant hexylene bisstearamide are thoroughly mixed by stirring, and the length-to-diameter ratio L / D is added to be 24...

Embodiment 3

[0043] Take by weighing 100 parts of low-density polyethylene with a melting index of 0.5g / 10min, 5 parts of polyvinyl chloride with a melting index of 1g / 10min, 1 part of chlorinated polyethylene with a mass content of chlorine element of 30%, 20 parts of tri(tribromo Phenoxy)triazine, 10 parts of antimony trioxide, 0.3 part of flame retardant synergist 2,3-dimethyl-2,3-diphenylbutane, 0.1 part of heat stabilizer barium stearate, 0.1 Part plasticizer diisooctyl phthalate, 0.1 part primary antioxidant N, N'-bis[β(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hydrazine, 0.1 part Secondary antioxidant bis(2,4-di-tert-butylphenyl)pentaerythritol diphosphite, 0.2 parts of light stabilizer 2-(2'-hydroxy-3',5'-di-tert-amylphenyl)benzo Triazole, 0.4 parts of light stabilizer poly{[6-[(1,1,3,3-tetramethylbutyl)amino]]-1,3,5-triazine-2,4-bis[(2 ,2,6,6,-tetramethyl-piperidinyl)imino]-1,6-hexadiene[(2,2,6,6-tetramethyl-4-piperidinyl)imino] } and 0.2 parts of lubricant hexamethylene bisste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com