Tin-zinc-bismuth-copper leadless solder with low cost and welding spot thereof

A lead-free solder, tin-zinc-bismuth technology, used in welding/cutting media/materials, welding media, welding equipment, etc. problems, to achieve the effect of good bonding strength and reliability, excellent spreading performance, and pollution-free welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

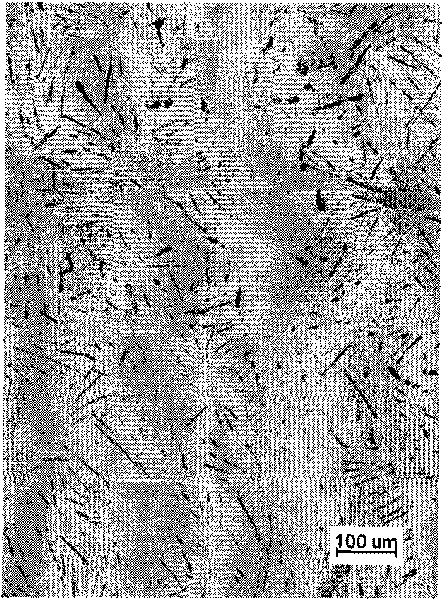

Image

Examples

Embodiment 1

[0025] A lead-free tin-zinc-bismuth-copper solder alloy, the composition and mass percentage of which are: Sn-6.0Zn-1.0Bi-0.5Cu. The preparation method is as follows: put the alloy raw materials into the furnace for smelting according to the ratio, and set the melting temperature to 300°C. After all the alloy components are completely melted, stir the liquid alloy properly to eliminate gravity segregation, stir evenly, and cast it into bars for later use.

Embodiment 2

[0027] A lead-free tin-zinc-bismuth-copper solder alloy, its composition and mass percentage are: Sn-10.0Zn-3.0Bi-1.0Cu. Its preparation method is with embodiment 1.

Embodiment 3

[0029] A lead-free tin-zinc-bismuth-copper solder alloy, its composition and mass percentage are: Sn-9.0Zn-3.0Bi-0.7Cu. Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com