Bug repairing apparatus

A defect repairing and installation technology, which is applied in the field of defect repairing devices, can solve problems such as optical fiber deformation, durability decline, and inability to process substrates, and achieve the effect of a relatively short distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, a defect repairing device according to an embodiment of the present invention will be described with reference to the drawings.

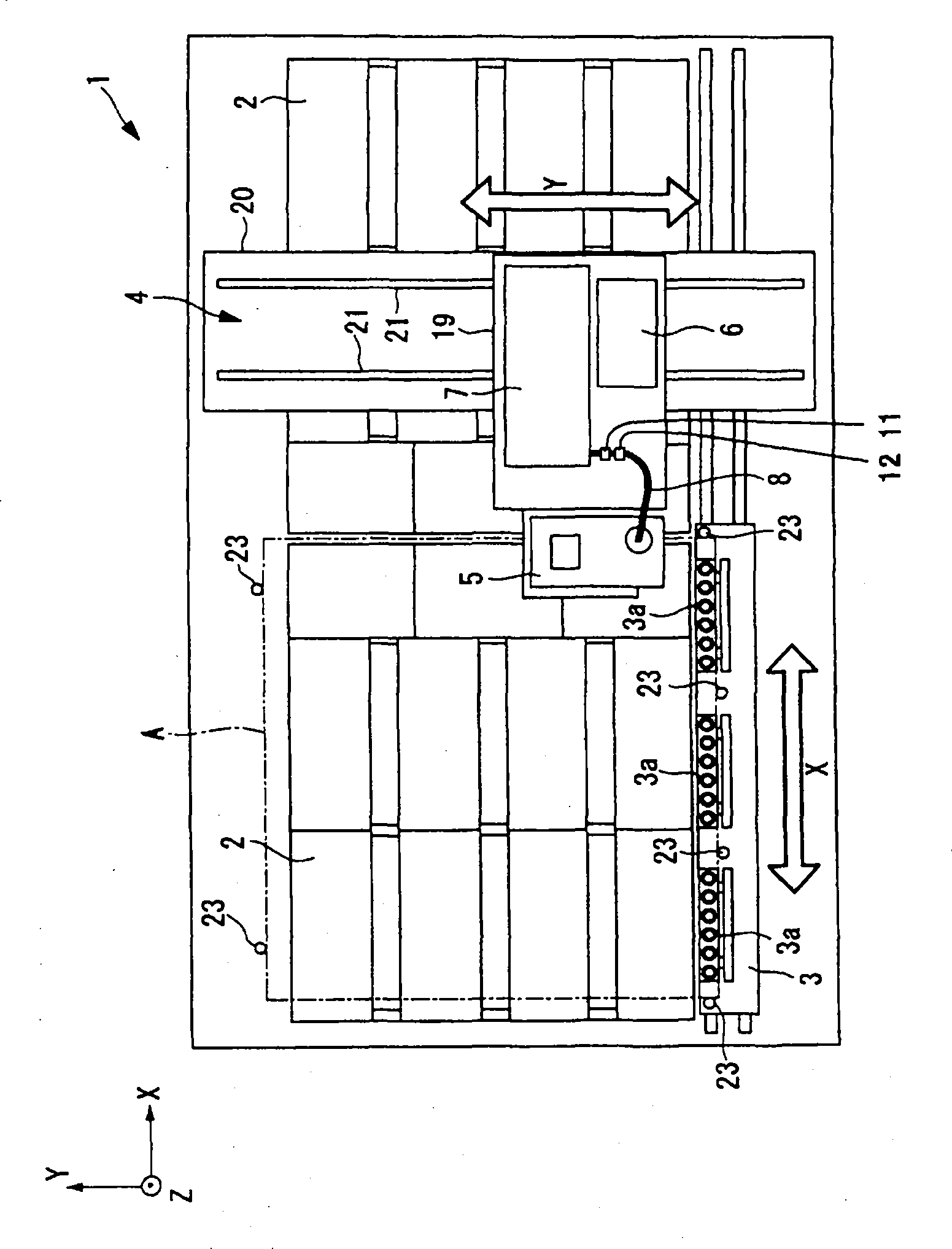

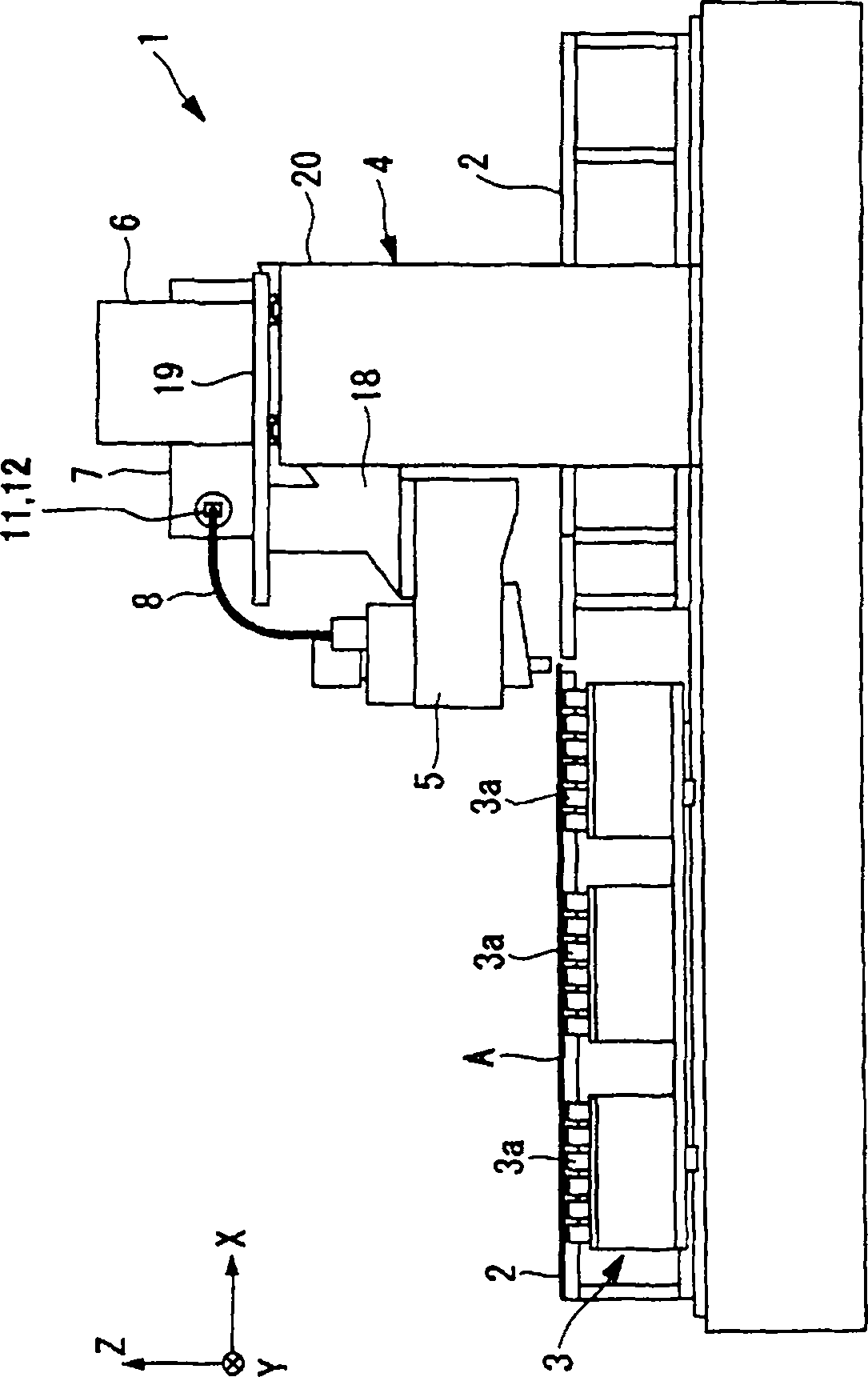

[0046] Figure 1A and Figure 1B It is a top view and a front view which show the defect repairing apparatus 1 which concerns on one Embodiment of this invention.

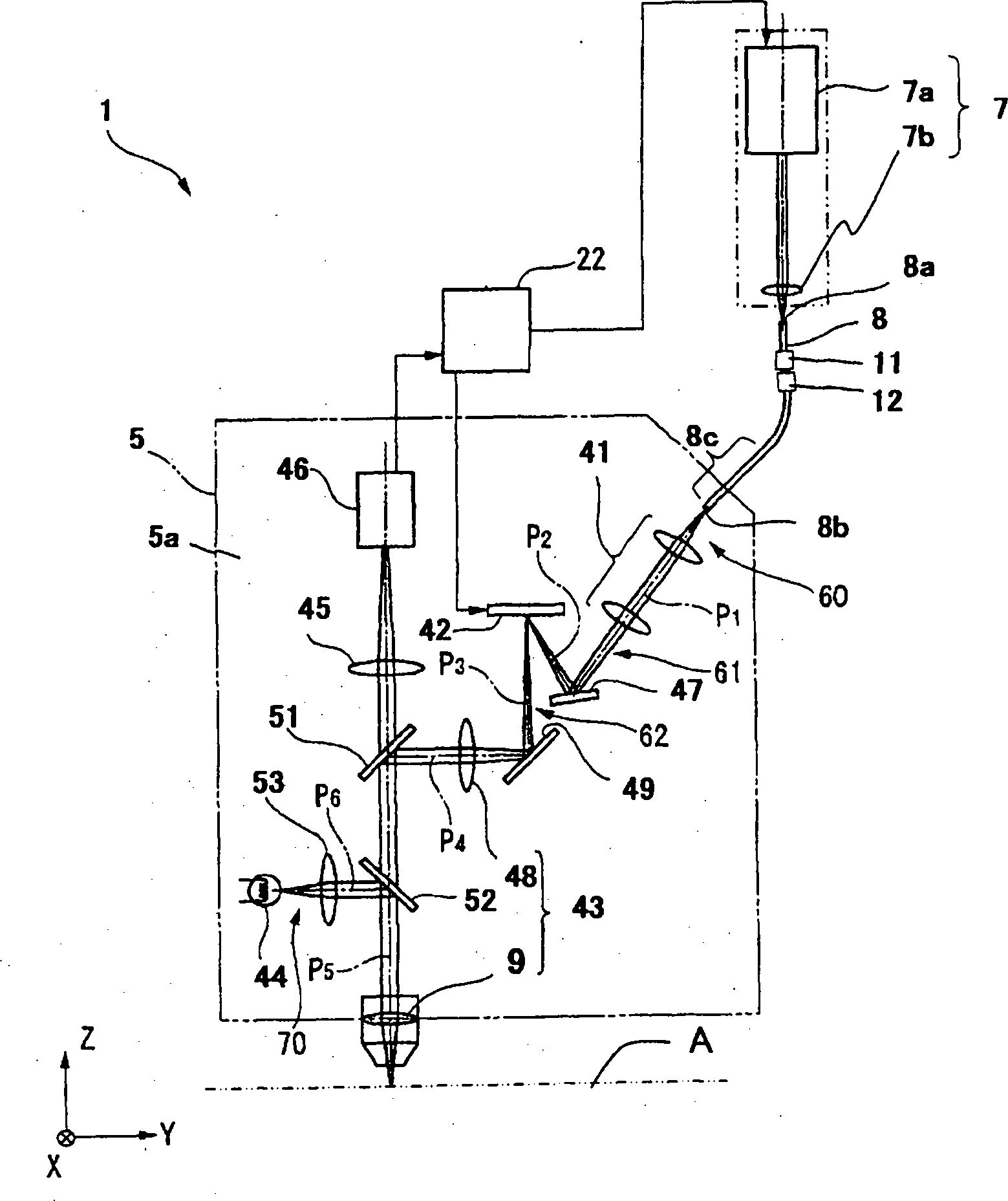

[0047] figure 2 It is a schematic structural diagram for explaining the internal structure of the processing head 5 of the defect repairing apparatus 1.

[0048] Figure 3A and Figure 3B It is a schematic side view and a schematic front view for explaining the optical fiber 8 and the mode scramblers 11 and 12 of the defect repairing device 1 .

[0049] The defect repairing device 1 is used, for example, for detecting a short circuit in a wiring portion, photoresist leakage, etc., in a glass substrate A on which a circuit pattern is formed by a photolithography process step in a manufacturing process of an FPD such as a liquid crystal display (LCD). When there a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com