Fiber composite and multi-layer perfluorinated cross-linked doped ion-exchange membrane

A technology of doping ions and fiber composites, which is applied in the field of functional polymer composite materials, and can solve problems such as alkali instability, increased gas permeability, and poor chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

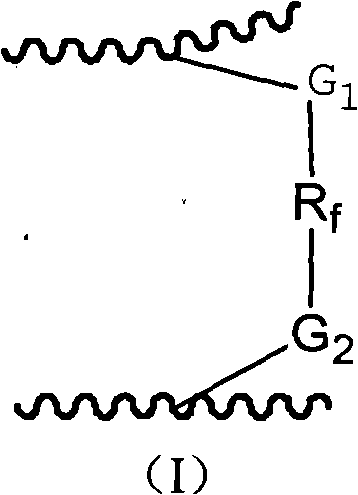

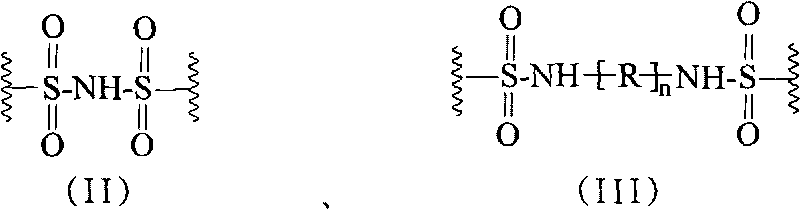

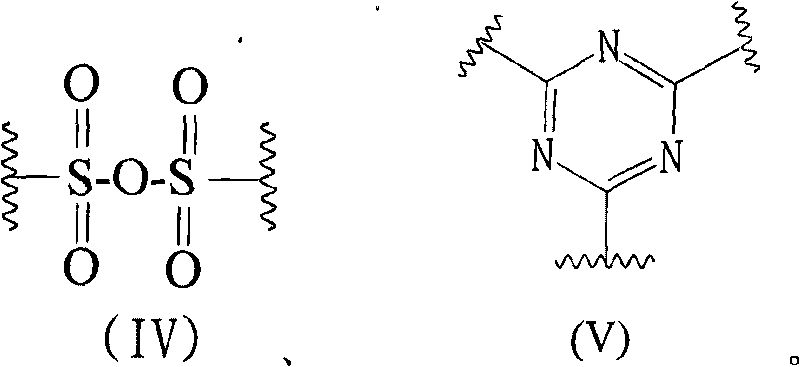

[0101] Convert the repeating unit to

[0102]

[0103] , polymer with EW=1000 and vanadium carbonate (accounting for 0.01% of resin mass), Zr(HPO with a particle size of 0.005 μm) 4 ) 2 (Zr(HPO 4 ) 2 The mass ratio with resin is 3: 100) is dispersed in propanol-water, makes total mass concentration and is 5% propanol-water solution, then adding mass concentration is the perfluoromalonyl peroxide DMF solution of 5%, to Add H to the above solution 3 PO 4 -SiO 2 Modified polytetrafluoroethylene fibers (1 μm in diameter, 50 μm in length, 7:100 mass ratio to polymer resin) were then cast into a horizontally placed polytetrafluoroethylene mold and vacuum-dried at 80°C for 12 hours. The membrane was peeled off to obtain a single-layer perfluorosulfonic acid cross-linked bridge (I) doped ion membrane (single-layer membrane 1#). Then, the above two single-layer perfluorinated cross-linked ion-doped membranes were stacked and hot-pressed to prepare a vanadium ion-bonded double...

Embodiment 2

[0105] Convert the repeating unit to

[0106]

[0107] , EW = 800 polymer resin, SiO with a particle size of 0.03 μm 2 (SiO 2 The mass ratio with perfluorosulfonic acid resin is 5:100), and the surface phosphorylated alkali-free glass fiber (diameter is 0.05 μm, length is 5 μm, without mass ratio with perfluorosulfonic acid resin is 1:40) is fully Mixed, then extruded to obtain a film with a thickness of 30 μm, and then the film was soaked in NH 4 Cl in DMF for 5 hours. The soaked membrane was then placed in triethylamine at 200°C for 2 hours to obtain a cross-linked membrane. The membrane was sequentially treated with KOH solution and hydrochloric acid solution to obtain an ion exchange membrane (single-layer membrane 2#) with a cross-linked bridge structure (II).

[0108] Convert the repeating unit to

[0109]

[0110] , polymer resin with EW=1200 and tetraphenyl tin are extruded into a film with a thickness of 20 μm by a twin-screw extruder, and then the film is ...

Embodiment 3

[0112] Convert the repeating unit to

[0113]

[0114] , the polymer resin of EW=1100, lanthanum acetate (lanthanum acetate accounts for 0.001% of resin mass) and H 3 PW 12 o 40 (resin and H 3 PW 12 o40 The mass ratio is 100:1) in the solvent to make a polymer solution with a total mass concentration of 3%, cast into a film, and then this film is cross-linked through 50KGy radiation to obtain a cross-linked bridge structure with a thickness of 10 μm as (I ) ion membrane (monolayer membrane 4#).

[0115] Convert the repeating unit to

[0116]

[0117] , polymer resin of EW=940, Ru-DMSO complex (accounting for 0.1% of resin quality) and H 3 PW 12 o 40 (Polymer and H 3 PW 12 o 40 mass ratio of 100:20) was dispersed in DMSO to obtain a DMSO solution with a total mass concentration of 30%, adding sulfuric acid-ZrO 2 Modified polytetrafluoroethylene fibers (0.2 μm in diameter, 80 μm in length, and a weight ratio of 7:100 to the polymer resin) were then treated at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com