Fire control sprayer

A sprinkler and fire-fighting technology, which is applied in fire rescue and other directions, can solve the problems of low fire extinguishing capacity, high rotation speed, and small water spray particles, and achieve the effect of large sprinkler coverage area, stable performance, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

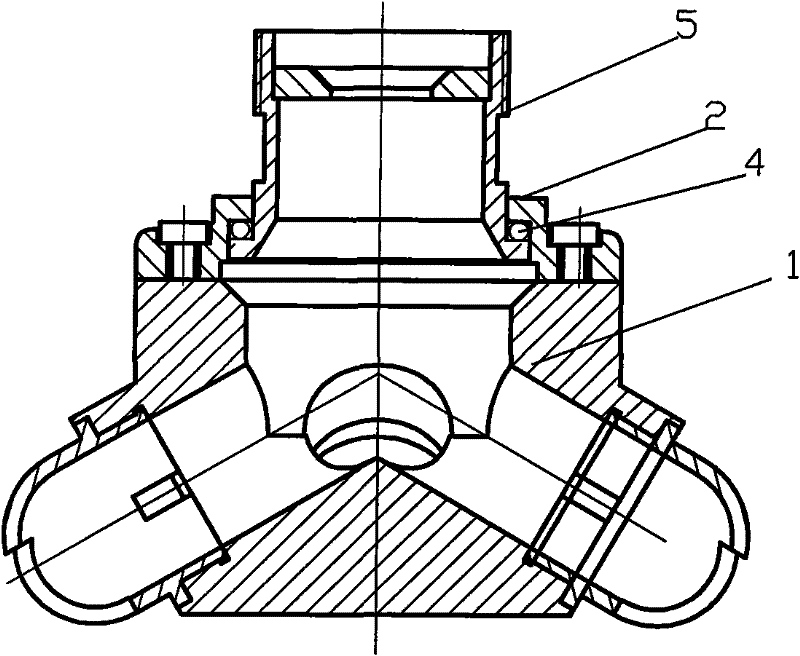

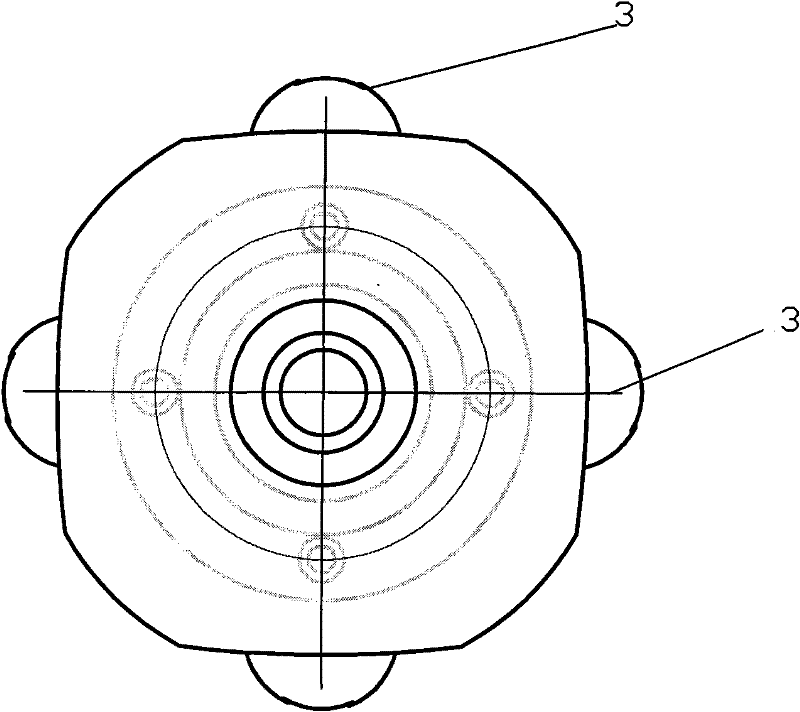

[0019] The top of the lower body 1 is connected with the upper cover 2 through threads, and the interior of the lower body 1 is provided with a plurality of rectifying water channels, the water outlet of the rectifying water channels is connected with the torque adjustment nozzle 3 through the inner card, and the top of the rectifying water channel communicates with one end of the water inlet pipe 5; The other end of the water inlet pipe 5 stretches out from the loam cake 2; a bearing 4 is arranged between the water inlet pipe 5 and the loam cake 2, so the water inlet pipe 5 and the loam cake 2 can rotate relatively.

Embodiment 2

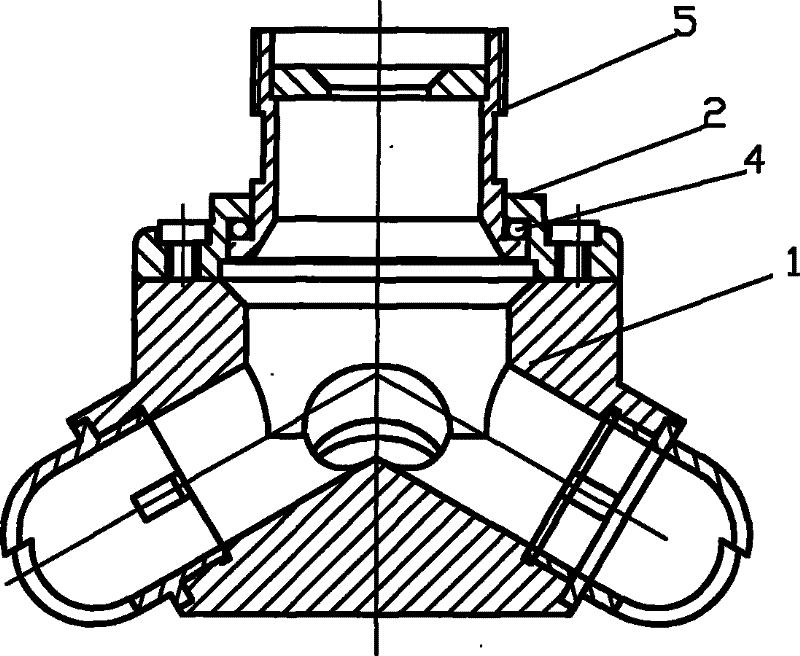

[0021] Balls are arranged between the water inlet pipe 5 and the upper cover 2, and other structures are the same as in the first embodiment.

[0022] The working principle of the present invention is described as follows

[0023] After the water flow with a certain pressure enters the water inlet pipe, it is sprayed out through the rectifying water channel and the torque adjustment nozzle. If the torque adjustment nozzle is adjusted to a suitable angle along the center line of the nozzle, under the impact of the water flow, it will rotate along the center line of the water inlet pipe. Torque makes the lower body rotate, the greater the torque, the higher the rotation speed. The advantage of rotating water spray is to spray water evenly within the range to be protected. The speed of the nozzle when rotating the water spray determines the size of the water spray particles. The higher the speed, the more serious the atomization phenomenon, the smaller the water spray particles,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com