Walnut barley nutritional powder and processing method thereof

A technology of highland barley powder and nutritional powder, applied in the fields of application, food preparation, food science, etc., can solve the problems of high cost and unfavorable promotion in Qinghai-Tibet area, and achieve the effects of cost economy, good social and economic benefits, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

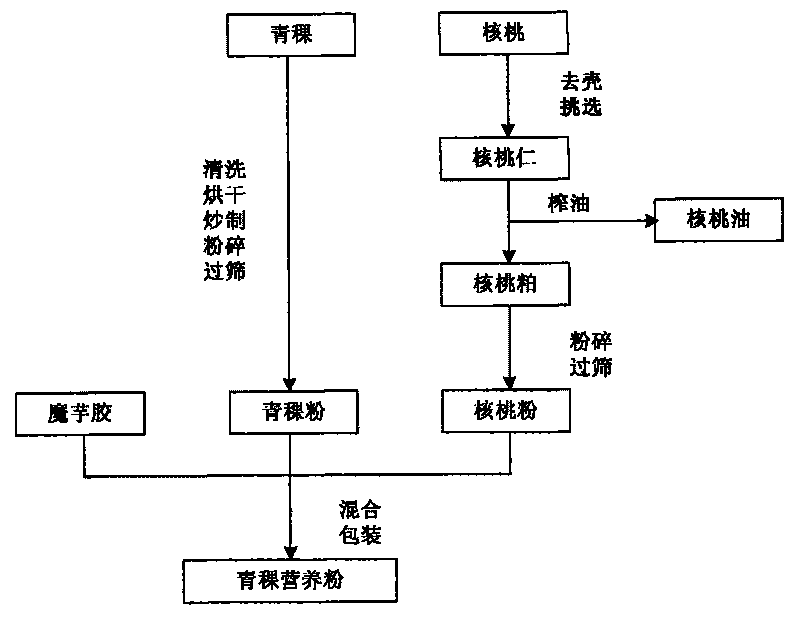

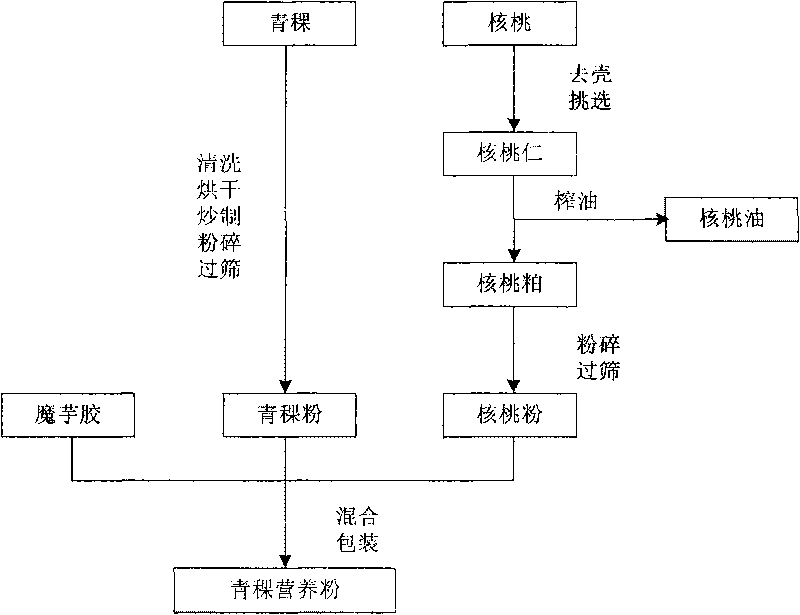

[0022] Such as figure 1 shown. Processing a kind of walnut highland barley nutrition powder, processing method is as follows:

[0023] Wash the highland barley, dry it, and fry it in a frying pan at 140°C to 200°C until the highland barley is completely cooked but not burnt, which takes about 10 minutes to 20 minutes. The fried highland barley is crushed and passed through a 100-120 mesh sieve to obtain the raw material of highland barley powder for later use.

[0024] The selected walnut kernels are put into an oil press to extract walnut oil through a cold rolling process to obtain a degreased walnut cake. The temperature of the obtained walnut cake is lower than 70 DEG C, and the fat content is lower than 5%. The walnut cake is crushed and passed through a 100-120 mesh sieve to obtain low-fat walnut powder for later use.

[0025] Mix highland barley powder and walnut powder evenly according to the formula ratio at 65°C, then add appropriate food additives as required, a...

Embodiment 2

[0028] Process a kind of walnut highland barley nutrient powder, do not repeat again with the same part in embodiment one, and its difference is:

[0029] Konjac gum is added when the highland barley powder and walnut powder are mixed.

[0030] The weight formula of highland barley powder, walnut powder and konjac gum is: highland barley powder 14-18g, walnut powder 2-3g, konjac gum 1.1-0.9g. The optimal formula ratio is: highland barley powder 16g, walnut powder 3g, konjac gum 1g.

[0031] Essence can also be properly added to the above-mentioned nutrition powder to adjust the flavor.

Embodiment 3

[0033] Process a kind of highland barley nutrient powder, and the identical part is no longer repeated in embodiment two, and its difference is:

[0034]Sucrose is added to the nutritional powder, and the weight of each component is composed of: highland barley powder 14-18g, walnut powder 2-3g, sucrose 12-18g, konjac gum 0.8-0.6g; the best formula is: highland barley powder 16g, walnut powder 2g , sucrose 16g, konjac gum 0.7g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com