Image sensor and method of fabricating the same

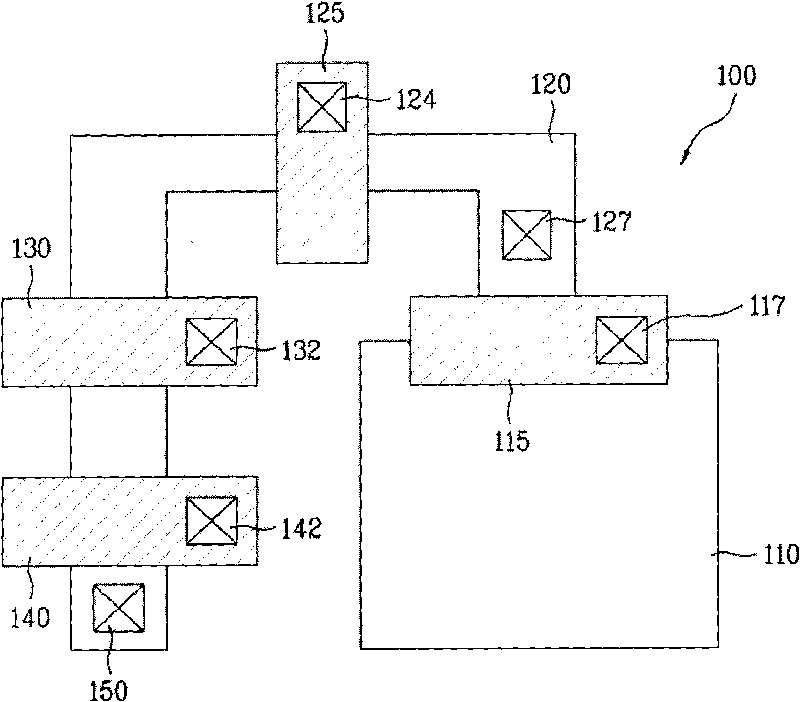

An image sensor and pattern technology, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve problems such as increased leakage current, inability to form contacts well, and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, technical concerns matters and features of the present invention will be clearly understood through the description of the accompanying drawings and embodiments. Preferred embodiments of the present invention will be described below.

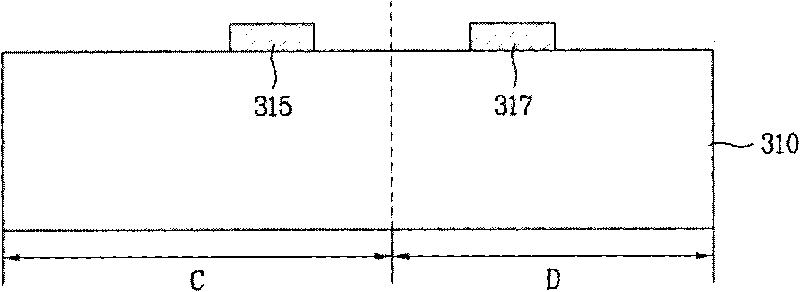

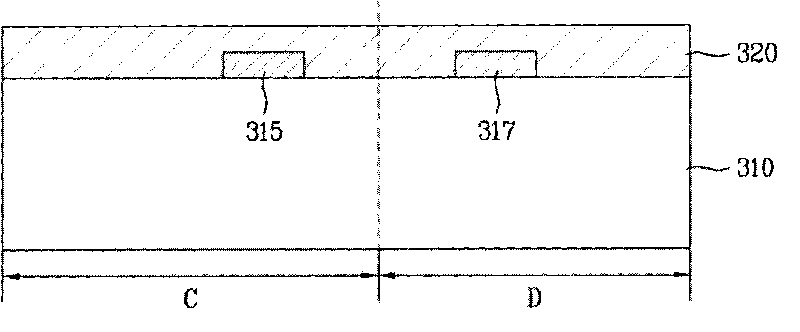

[0020] 2A to 2F are longitudinal sectional views illustrating a method of manufacturing an image sensor according to one embodiment of the present invention.

[0021] First, as shown in FIG. 2A, a substrate (for example, a silicon substrate) 310 on which a pixel region C and a logic region D are defined is prepared. A unit pixel for detecting light is formed on a substrate in the pixel region C, and a logic circuit is formed in the logic region D, wherein the logic circuit includes at least one transistor for processing the light detected by the pixel region C into Electrical signals to obtain optical data.

[0022] At least one transistor is formed on the substrate in each of the pixel region C and the logic region D. FIG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com