Electrode slurry for plasma display and application thereof

A plasma display and electrode slurry technology, which is applied in the direction of gas discharge electrodes, electrode system manufacturing, circuits, etc., can solve the problems of high production cost, inelastic deformation of screen mesh, and complex branched chains of molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

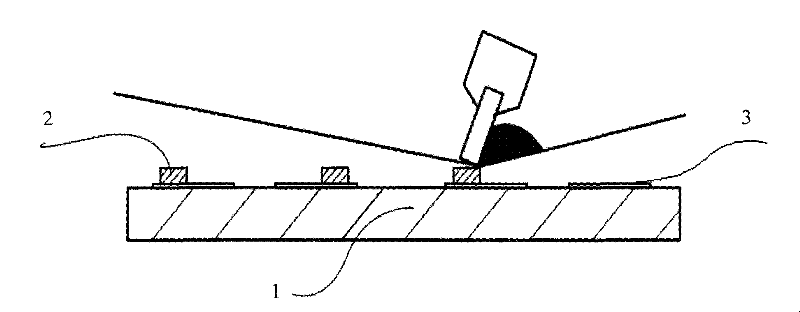

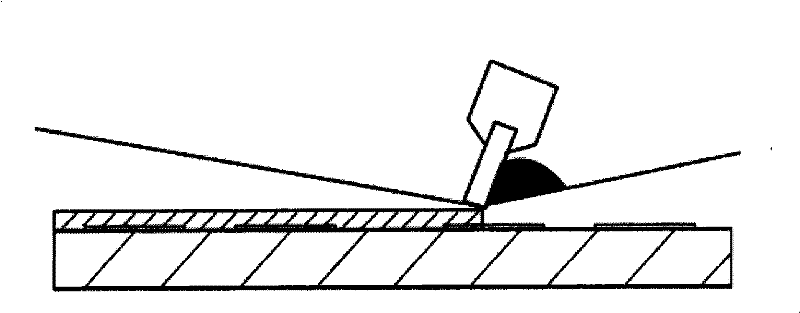

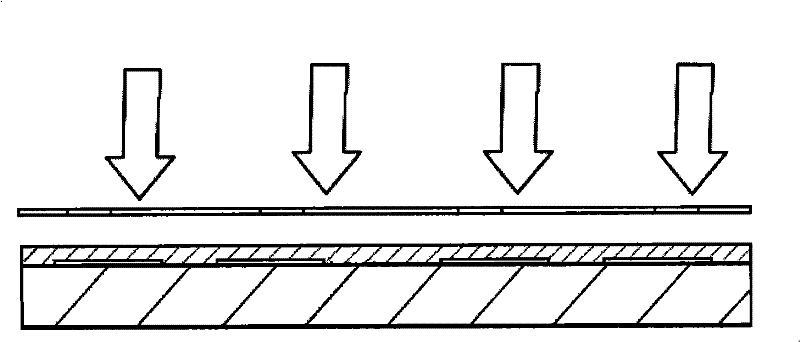

Method used

Image

Examples

Embodiment 1

[0033] Methyl methacrylate and methacrylic acid were mixed in a weight ratio of 4:1 to form a copolymer, and this copolymer was mixed with glycidyl (meth)acrylate in a ratio of 4:1 to form a prepolymer. According to prepolymer 30%, benzophenone 4%, butyl acrylate 20%, average particle size distribution of 1-8μm and average specific surface area of 0.01-2.0m 2 / g silver powder 40%, Bi 2 o 3 - ZnO-based low-melting point glass powder 5% and butanol 1% by weight, the above materials are mixed and stirred evenly, and adjusted to PH=7 with ammonia water to form a photosensitive electrode slurry.

Embodiment 2

[0035] Methyl methacrylate and methacrylic acid were mixed in a weight ratio of 4:1 to form a copolymer, and this copolymer was mixed with glycidyl (meth)acrylate in a ratio of 4:1 to form a prepolymer. According to the prepolymer 30%, benzophenone 4%, styrene 10%, butyl acrylate 5%, vinyl acetate 5%, the average particle size distribution is 1-8μm and the average specific surface area is 0.01-2.0m 2 / g silver powder 40%, Bi 2 o 3 - ZnO-based low-melting point glass powder 5% and butanol 1% by weight, the above materials are mixed and stirred evenly, and adjusted to PH=7 with ammonia water to form a photosensitive electrode slurry.

Embodiment 3

[0037] Methyl methacrylate and methacrylic acid were mixed at a weight ratio of 4:1 to form a copolymer, and this copolymer was mixed with glycidyl (meth)acrylate at a ratio of 5:1 to form a prepolymer. According to prepolymer 32%, diphenylacetone 2%, butyl acrylate 20%, average particle size distribution of 1-8μm and average specific surface area of 0.01-2.0m 2 / g silver powder 40%, Bi 2 o 3 - ZnO-based low-melting point glass powder 5% and butanol 1% by weight, the above materials are mixed and stirred evenly, and adjusted to PH=7 with ammonia water to form a photosensitive electrode slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com