Flue gas desulfurization and denitrification optimization control method based on hysteresis model

A desulfurization, denitrification and optimal control technology, applied in the field of desulfurization and denitrification, can solve the problems of increasing the amount of ammonia sprayed, the concentration of nitrogen oxides at the outlet exceeding the standard, and it is difficult to control the spraying amount of limestone slurry, so as to achieve the effect of improving precision and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

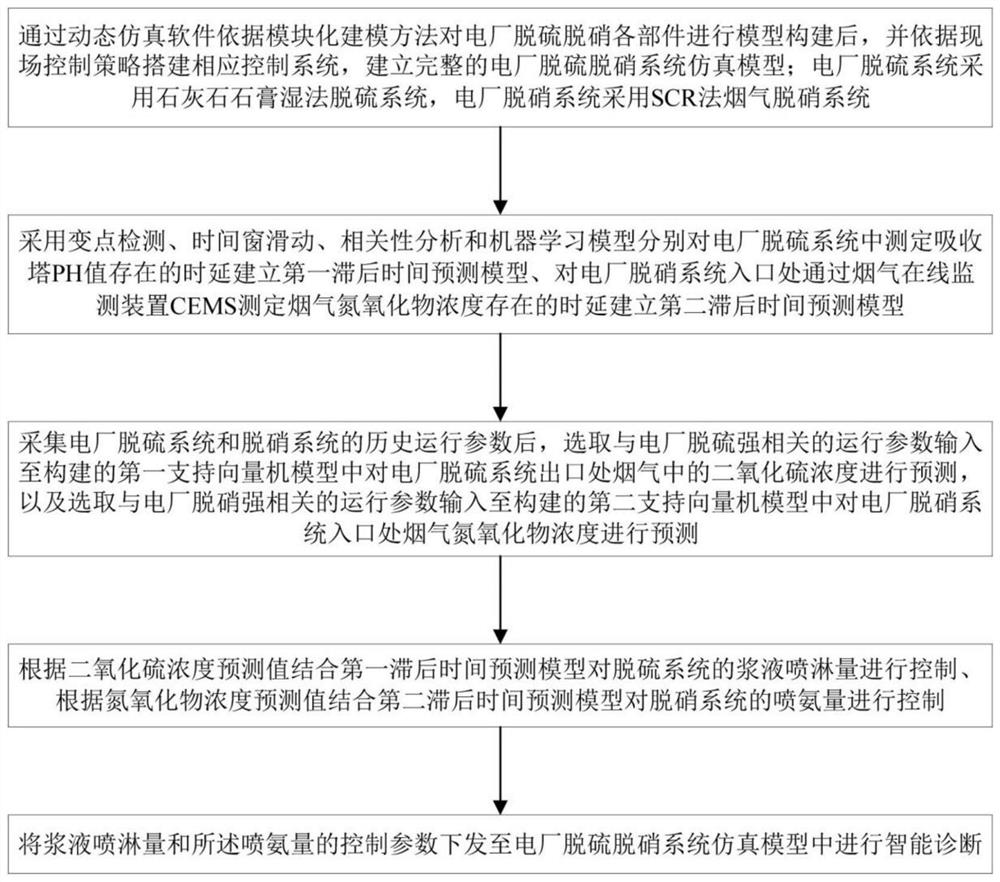

[0075] Such as figure 1 As shown, this embodiment 1 provides an optimal control method for flue gas desulfurization and denitrification based on a hysteresis model, and the optimal control method for flue gas desulfurization and denitrification includes:

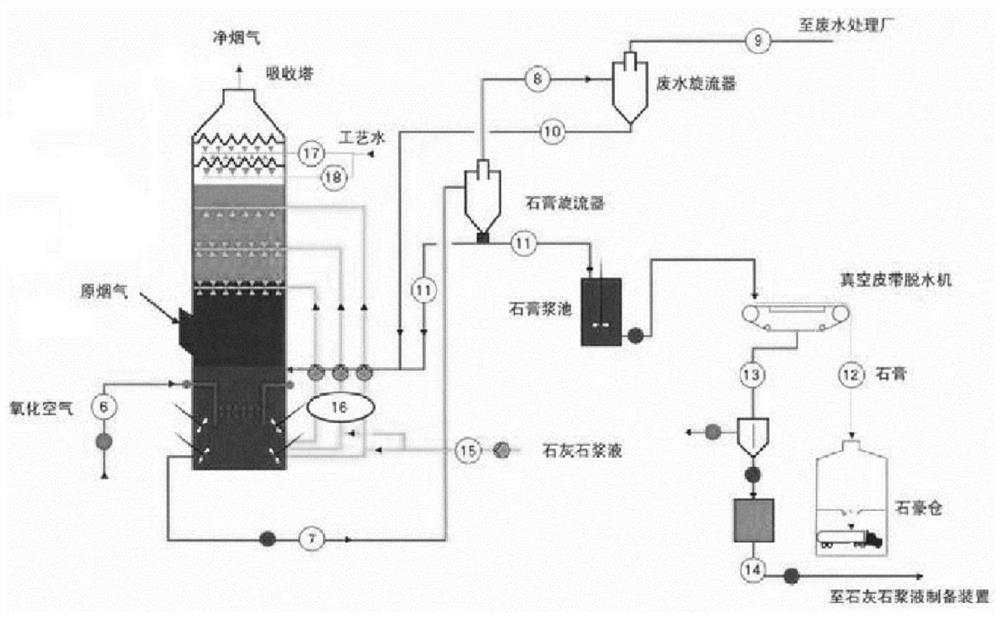

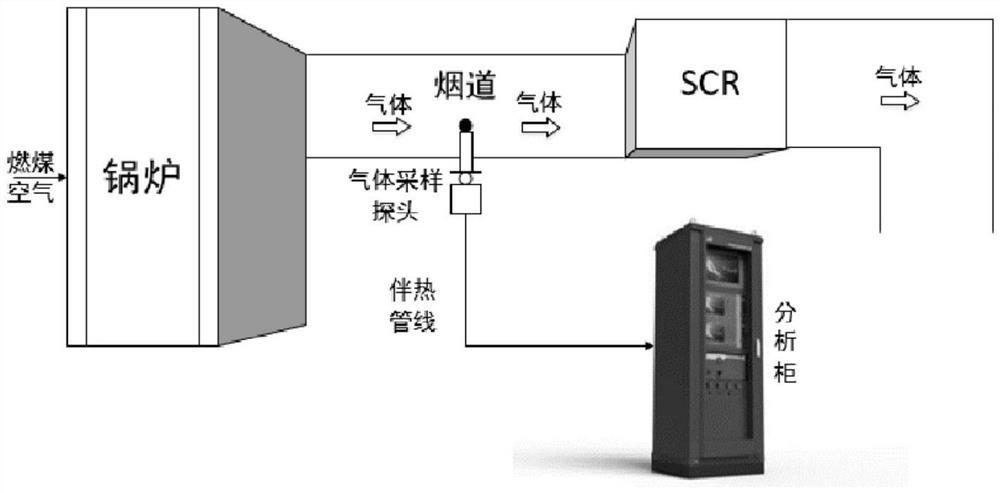

[0076] After the dynamic simulation software is used to model the desulfurization and denitrification components of the power plant based on the modular modeling method, and the corresponding control system is built according to the on-site control strategy, a complete simulation model of the desulfurization and denitrification system of the power plant is established; the desulfurization system of the power plant uses limestone-gypsum Wet desulfurization system, the denitrification system of the power plant adopts the SCR method flue gas denitrification system;

[0077] Using change point detection, time window sliding, correlation analysis and machine learning model to establish the first lag time prediction model for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com