Electrode slurry for plasma display and application thereof

A plasma display and electrode slurry technology, which is applied in the manufacture of electrode systems, circuits, electrical components, etc., can solve problems such as complex branched chains of molecules, non-elastic deformation of screen mesh, and failure of electrode patterns to meet precision requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

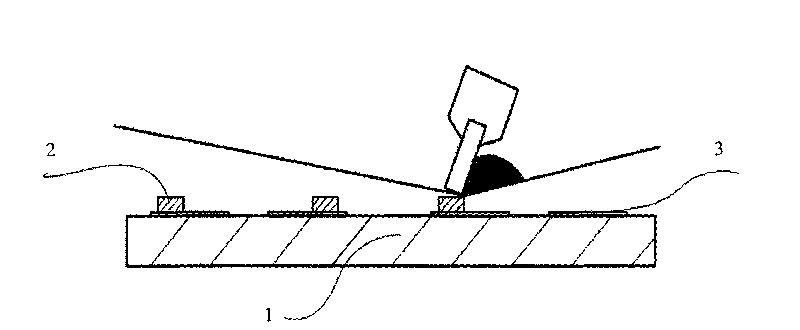

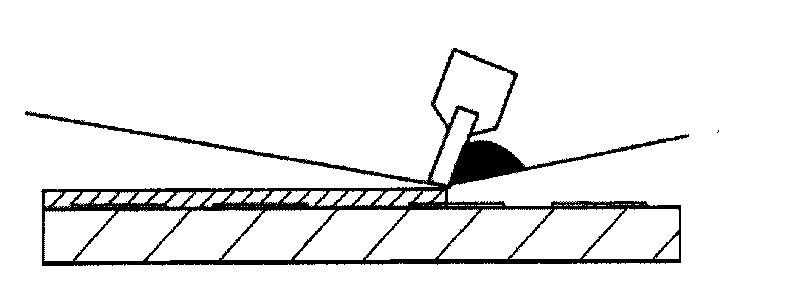

Image

Examples

Embodiment 1

[0033] Methyl methacrylate and methacrylic acid were mixed in a weight ratio of 4:1 to form a copolymer, and this copolymer was mixed with glycidyl (meth)acrylate in a ratio of 4:1 to form a prepolymer. According to prepolymer 30%, benzophenone 4%, butyl acrylate 20%, average particle size distribution of 1-8μm and average specific surface area of 0.01-2.0m 2 / g silver powder 40%, Bi 2 o 3 - ZnO-based low-melting point glass powder 5% and butanol 1% by weight, the above materials are mixed and stirred evenly, and adjusted to PH=7 with ammonia water to form a photosensitive electrode slurry.

Embodiment 2

[0035] Methyl methacrylate and methacrylic acid were mixed in a weight ratio of 4:1 to form a copolymer, and this copolymer was mixed with glycidyl (meth)acrylate in a ratio of 4:1 to form a prepolymer. According to the prepolymer 30%, benzophenone 4%, styrene 10%, butyl acrylate 5%, vinyl acetate 5%, the average particle size distribution is 1-8μm and the average specific surface area is 0.01-2.0m 2 / g silver powder 40%, Bi 2 o 3 - ZnO-based low-melting point glass powder 5% and butanol 1% by weight, the above materials are mixed and stirred evenly, and adjusted to PH=7 with ammonia water to form a photosensitive electrode slurry.

Embodiment 3

[0037] Methyl methacrylate and methacrylic acid were mixed at a weight ratio of 4:1 to form a copolymer, and this copolymer was mixed with glycidyl (meth)acrylate at a ratio of 5:1 to form a prepolymer. According to prepolymer 32%, diphenylacetone 2%, butyl acrylate 20%, average particle size distribution of 1-8μm and average specific surface area of 0.01-2.0m 2 / g silver powder 40%, Bi 2 o 3 - ZnO-based low-melting point glass powder 5% and butanol 1% by weight, the above materials are mixed and stirred evenly, and adjusted to PH=7 with ammonia water to form a photosensitive electrode slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com