Cobalt oxide/carbon composite nano wave-absorbing material and preparation method thereof

A nano-wave absorbing material, cobalt oxide technology, applied in cobalt oxide/cobalt hydroxide, inorganic material magnetism, hydrogen production and other directions, can solve the problems of principle and technical difficulties, complicated operation process, harsh reaction conditions, etc. The effect of cost, simple conditions, and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Weigh 0.3g Co(NO 3 ) 2 ·6H 2 O, add 31mL of water, ethanol and diethanolamine mixed solvent (water:ethanol:diethanolamine=20:10:1) under magnetic stirring. After dissolving completely, put the solution into the polytetrafluoroethylene reactor .

[0040] (2) Put the reaction kettle into a stainless steel jacket and put it in an oven to heat to 180°C for 12 hours.

[0041] (3) After the reaction kettle is naturally cooled to room temperature, the supernatant liquid is taken out and the lower layer precipitate is separated by centrifugation, washed with absolute ethanol 3 times, and dried at 80°C to obtain the flake cobalt hydroxide precursor.

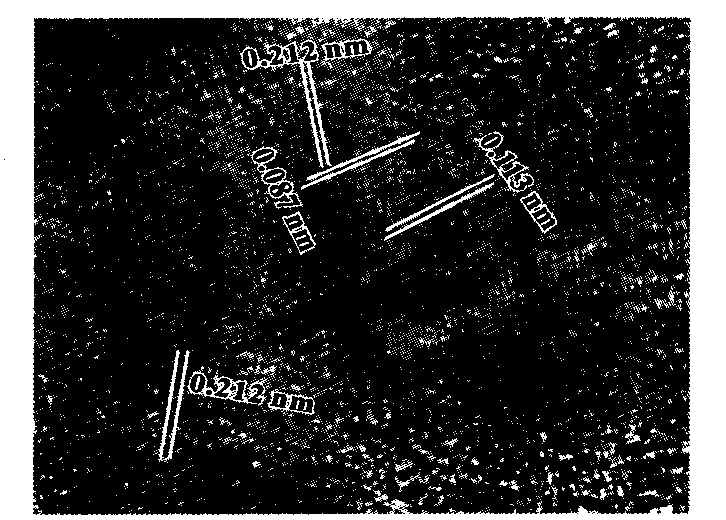

[0042] (4) Mix the precursor and oleylamine in a quartz tube at a volume ratio of 1:25, dissolve it ultrasonically, and then insert the quartz tube into a vertical tube furnace to quickly heat to 300°C, take out the quartz tube after 30 minutes, and add The absolute ethanol is allowed to stand, the precipitate is separated by centrif...

Embodiment 2

[0047] (1) Weigh 0.3g Co(NO 3 ) 2 ·6H 2 O, add 38mL of water, ethanol and diethanolamine mixed solvent (water:ethanol:diethanolamine=20:10:8) under magnetic stirring. After the solution is completely dissolved, put the solution into the polytetrafluoroethylene reactor .

[0048] (2) Put the reaction kettle into a stainless steel jacket and put it in an oven to heat to 180°C for 12 hours.

[0049] (3) After the reaction kettle is naturally cooled to room temperature, take out the supernatant liquid, centrifuge to separate the lower sediment, wash 3 times with absolute ethanol, and dry at 80°C to obtain the flower-like cobalt hydroxide precursor.

[0050] (4) Mix the precursor and oleylamine in a quartz tube at a volume ratio of 1:25, dissolve it ultrasonically, and then insert the quartz tube into a vertical tube furnace to quickly heat to 300°C, take out the quartz tube after 30 minutes, and add The absolute ethanol is allowed to stand, the precipitate is separated by centrifugation...

Embodiment 3

[0055] (1) Weigh 0.3g Co(NO 3 ) 2 ·6H 2 O, add 31mL of water, ethanol and diethanolamine mixed solvent (water:ethanol:diethanolamine=20:1:10) under magnetic stirring. After it is completely dissolved, put the solution into the polytetrafluoroethylene reactor .

[0056] (2) Put the reaction kettle into a stainless steel jacket and put it in an oven to heat to 180°C for 12 hours.

[0057] (3) After the reaction kettle is naturally cooled to room temperature, the supernatant liquid is taken out and the lower sediment is separated by centrifugation, washed with absolute ethanol 3 times, and dried at 80°C to obtain the cobalt hydroxide precursor.

[0058] (4) Mix the precursor and oleylamine in a quartz tube at a volume ratio of 1:25, dissolve it ultrasonically, and then insert the quartz tube into a vertical tube furnace to quickly heat it to 300°C, take out the quartz tube after 60 minutes, and add The absolute ethanol is allowed to stand, the precipitate is separated by centrifugation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com