Permanent magnet with corrosion resistant coating and powder nanometer spraying method thereof

A technology of anti-corrosion coating and permanent magnet, which is applied in the field of surface chemical treatment of materials, and can solve problems that affect the service life of NdFeB permanent magnets, poor corrosion resistance of NdFeB alloys, and reduce product stability and reliability. , to achieve the effect of reducing production investment cost, ensuring safe production and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

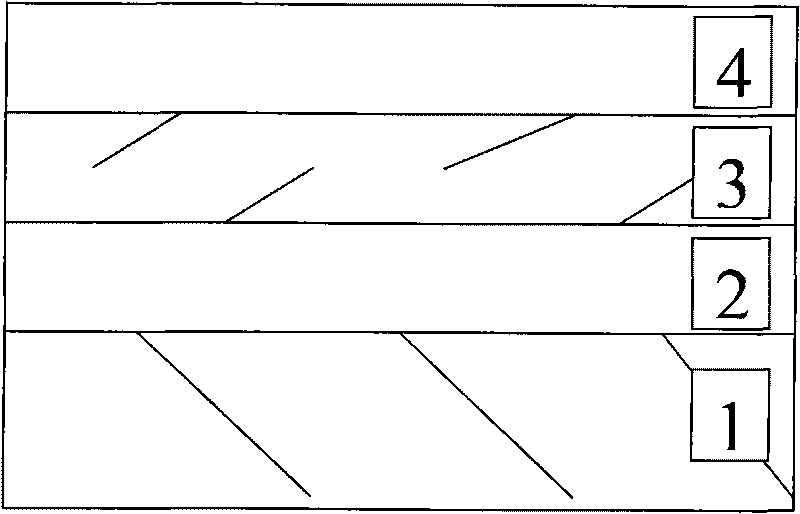

Embodiment 1

[0032] Choose 70*25*10 materials, chamfering and polishing: use mechanical vibration grinding and rolling chamfering method to polish sintered NdFeB permanent magnet materials; degreasing and degreasing: adding sodium phosphate, sodium carbonate or sodium hydroxide Carry out degreasing and degreasing; sandblasting and derusting; spray primer layer: on the surface of the permanent magnet, spray a kind of 0.5 micron thick hydroxyacrylic resin bottom layer with spray gun. Sensitization and activation treatment: Spray the surface sensitization activation solution on the surface of the article sprayed with the primer layer until the surface of the article is completely wet, and then rinse the article with pure aqueous solution; the surface sensitization activation solution contains hydroxyl 15 g / L of stannous alkyl sulfonate, 15 g / L of palladium chloride, and a transition layer thickness of 0.1 microns. Spraying the outermost layer with a spray gun: spray A agent and B agent to the...

Embodiment 2

[0034] Choose 70*25*10 materials, chamfering and polishing: adopt mechanical vibration grinding and rolling chamfering method to polish the bonded NdFeB permanent magnet material; degreasing and degreasing: adding sodium phosphate, sodium carbonate or hydroxide Sodium for degreasing and degreasing; sand blasting for rust removal; spraying primer layer: on the surface of the permanent magnet, spray a 2 micron thick epoxy resin primer layer on the surface of the permanent magnet. Sensitization and activation treatment: Spray the surface sensitization activation solution on the surface of the article sprayed with the primer layer until the surface of the article is completely wet, and then rinse the article with pure aqueous solution; the surface sensitization activation solution contains hydroxyl 25 g / L of stannous alkyl sulfonate, 5 g / L of palladium chloride, and a transition layer thickness of 0.3 microns. Spraying the outermost layer with a spray gun: spray A agent and B agen...

Embodiment 3

[0036]Choose 70*25*10 materials, chamfering and polishing: use mechanical vibration grinding and rolling chamfering method to polish sintered NdFeB permanent magnet materials; degreasing and degreasing: adding sodium phosphate, sodium carbonate or sodium hydroxide Degreasing and degreasing; sand blasting and rust removal; spraying primer layer: on the surface of the permanent magnet, spray a 1 micron thick hydroxyacrylic resin bottom layer with a spray gun. Sensitization and activation treatment: Spray the surface sensitization activation solution on the surface of the article sprayed with the primer layer until the surface of the article is completely wet, and then rinse the article with pure aqueous solution; the surface sensitization activation solution contains hydroxyl 20 g / L of stannous alkyl sulfonate, 10 g / L of palladium chloride, and a thickness of 0.2 microns in the transition layer. Spraying the outermost layer with a spray gun: spray A agent and B agent on the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com