Inner flame energy-concentrating riser pipe type gas burner

A technology of gas burners and burners, which is applied in the direction of gas fuel burners, burners, and the combination of multiple burners. It can solve the problems of insufficient melting point temperature, etc., and achieve improved heat load and good energy gathering effect. , Obvious effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

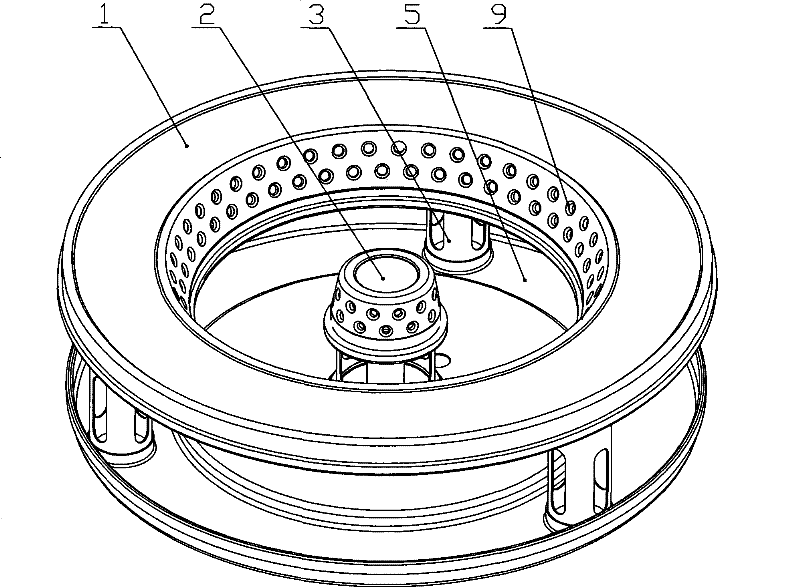

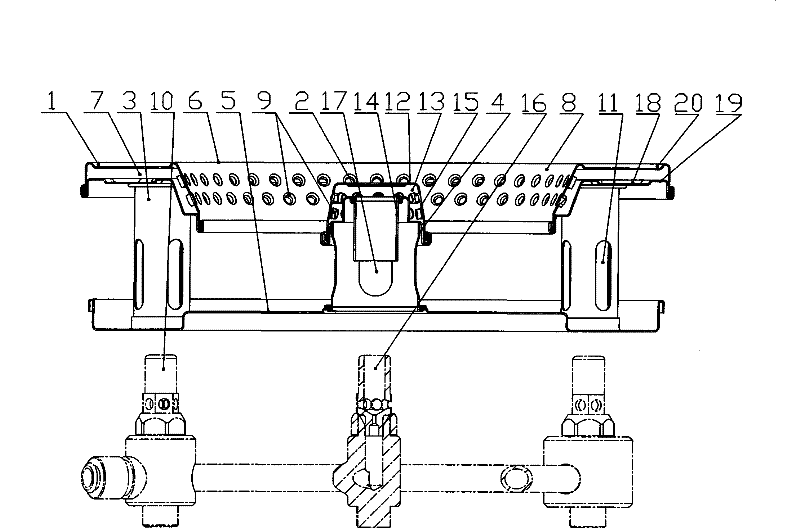

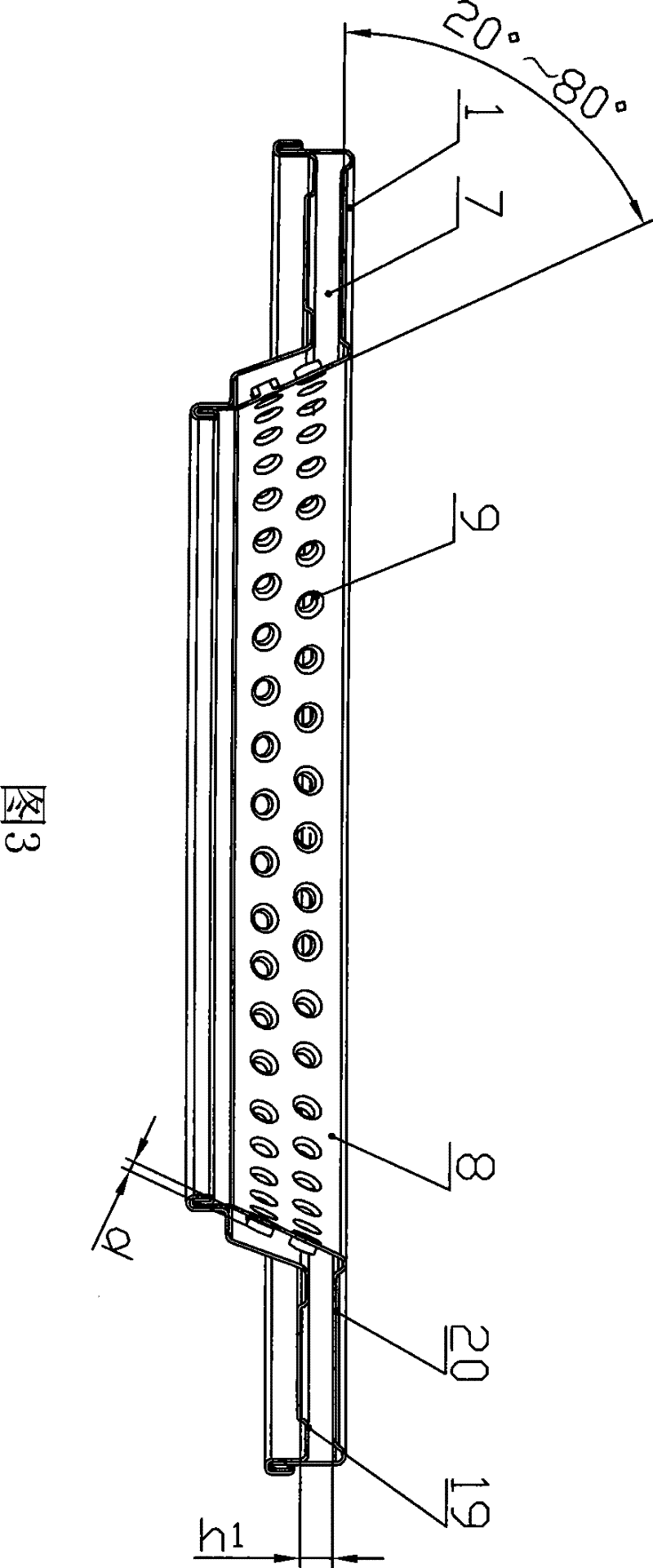

[0015] Embodiment 1: as figure 1 and figure 2 As shown, the internal flame type energy-gathering standpipe gas burner includes a large fire burner 1, a small fire burner 2, a large fire burner mixing tube 3, a small fire burner positioning tube 4 and a water storage tray 5, as image 3 As shown, the high-fire burner 1 includes an annular shell 6 and an inner cavity 7 of the annular shell. The inner ring 8 of the annular shell 6 is in the shape of a rounded frustum at an angle of 30° to the horizontal plane, and the inner ring 8 is provided with 2 fire holes. 9. There are 3 mixing tubes 3 of the high-fire burner, which are respectively vertically connected to the lower plane 18 of the annular shell 6 of the high-fire burner and the water accumulation tray 5 and are evenly distributed along the circumferential direction of the water accumulation tray 5. One end of the high-fire burner mixing tube 3 It communicates with the inner cavity 7 of the annular shell, and the other end...

Embodiment 2

[0016] Embodiment 2: the annular housing 6 of the high fire burner 1 is made up of the flat annular air inlet housing 19 and the flat annular high fire combustion housing 20 connected to each other, and the inner ring 8 of the flat annular high fire combustion housing 20 is in the shape of The horizontal plane is in the shape of a rounded frustum at an angle of 35°. The flat annular high-fire combustion shell 20 is arranged on the inner side of the flat annular air intake shell 19. The casing 12 is formed by punching and riveting stainless steel sheets, the mixing tube 14 of the small fire burner is connected with the round platform hat-shaped casing 12 by spot welding, and the rest are the same as in the first embodiment.

Embodiment 3

[0017] Embodiment 3: The inner ring 8 of the annular shell 6 is in the shape of a rounded truncated cone at an angle of 70° to the horizontal plane. There are 3 fire holes 9 on the inner ring 8. There are 5 mixing tubes 3 of the high-fire burner. There are 6 air intake slots 11 evenly distributed on the side of the mixing tube 3, and 3 fire discharge holes 9 are arranged on the outer surface 15 of the round platform hat-shaped housing 12, and the angle between the outer surface 15 and the horizontal plane is 80°. Four air inlets 17 are evenly distributed on the side of the positioning tube 4 of the low-fire burner, and the distance h from the upper end surface of the mixing tube 3 of the high-fire burner to the top surface of the annular housing cavity 7 is 1 And the distance h from the upper end surface of the mixing tube 14 of the small fire burner to the upper surface of the inner cavity 13 of the round platform hat-shaped shell 2 It is 4mm, and the diameter of fire hole 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com