Method for preparing polyethylene wax in solvent

A polyethylene wax and low-molecular-weight polyethylene technology, applied in the field of polymer wax synthesis, can solve the problems that the specific conditions of the raw materials have not been investigated and analyzed, and the problems have not been sufficiently analyzed, so as to prevent excessive cracking and carbon deposition, Good for heat transfer and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

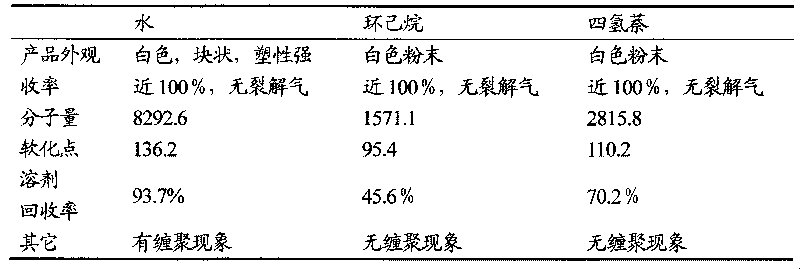

[0012] Take about 100g of high-density polyethylene (HDPE) into the autoclave, add 100ml of the selected solvent (water, cyclohexane, tetrahydronaphthalene), seal the autoclave, and purge the autoclave with nitrogen for about 10 minutes to replace and remove the air in the autoclave. Turn on the stirring device, raise the temperature to 360°C for 8 hours, cool down to room temperature, discharge, filter and dry, recover part of the solvent, and obtain low molecular weight polyethylene wax. The results are shown in Table 1.

[0013] The reaction results of different solvents in table 1

[0014]

[0015] As can be seen from Table 1, the polyethylene wax synthesized with tetralin and cyclohexane is a white powder, and the raw materials do not have entanglement phenomenon, but the tetralin boiling point is high, so the solvent recovery rate is higher; Polyethylene wax can be obtained, but the molecular weight is relatively high, and the raw materials are entangled on the stirre...

Embodiment 2

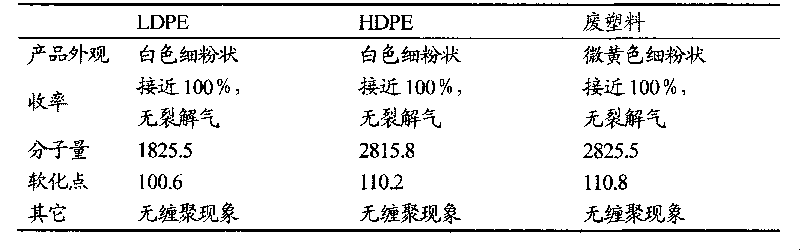

[0017] Using LDPE, HDPE and discarded PE packaging bags as raw materials, tetralin as the reaction solvent, the method is the same as in Example 1, and the results are shown in Table 2.

[0018] The comparison result of different reaction raw materials of table 2

[0019]

[0020] It can be seen from Table 2 that all three kinds of raw materials can be used to prepare low molecular weight polyethylene wax, the difference is that the color of the product prepared from waste plastics is slightly yellow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com