Round integrated oxidation ditch

An oxidation ditch, circular technology, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water/sewage multi-stage treatment, etc., can solve the problems of affecting effluent quality, poor sedimentation performance, immature technology, etc. Achieve the effect of avoiding dead corners and short circuits, small footprint and good precipitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

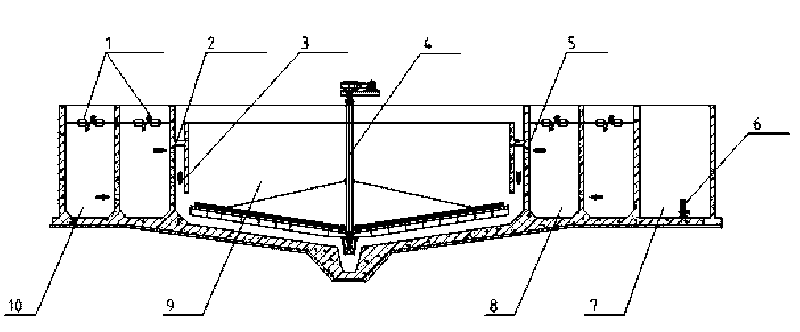

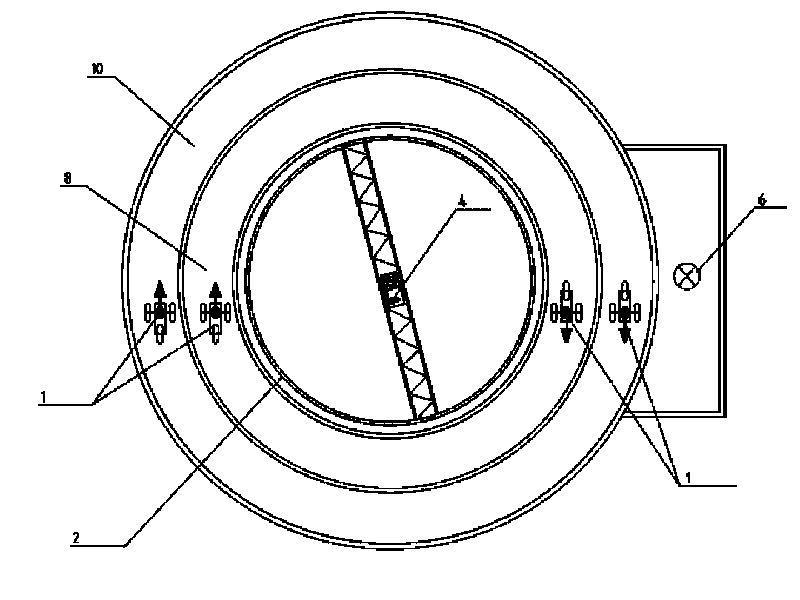

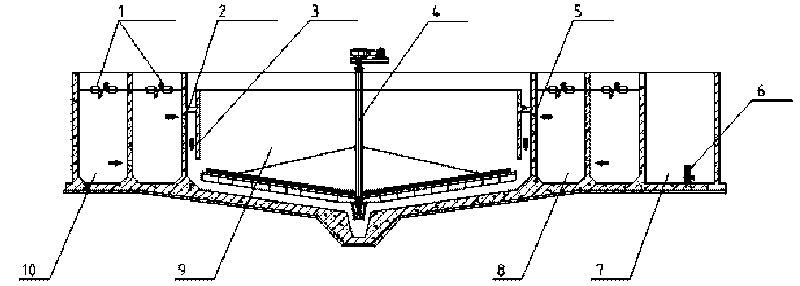

[0023] Implementation example of the present invention: the integrated circular oxidation ditch is a continuous, closed concentric reactor, and the outer two rings form the outer ditch 10 and the middle ditch 8 successively. A push-flow aerator 1 is set on the liquid surface, and the middle circle forms a secondary settling tank 9, and there is a mud scraper 4 in the secondary settling tank 9, and a water inlet skirt 3 is arranged on the peripheral wall of the secondary settling tank 9. There are water distribution holes 5 on the inner wall of the ditch 8; the mud collecting well 7 is arranged outside the ring, and there is a sludge pump 6 in the mud collecting well 7.

[0024] The distance between the water distribution holes 5 on the inner wall of the middle ditch 8 is 300 mm to 600 mm.

[0025] The diameter of the water distribution hole 5 is φ20mm~30mm.

[0026] There is an annular outlet weir 2 between the inner wall of the middle ditch 8 and the secondary settling tank ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com