Preparation method of black polyamide-imide coating and coating thereof, enameled wire

A polyamide-imide, polyamide-imide resin technology, applied in coatings, plastic/resin/wax insulators, organic insulators, etc., can solve the problem of poor black coloring effect, poor heat resistance, and unsatisfactory hue. Production requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

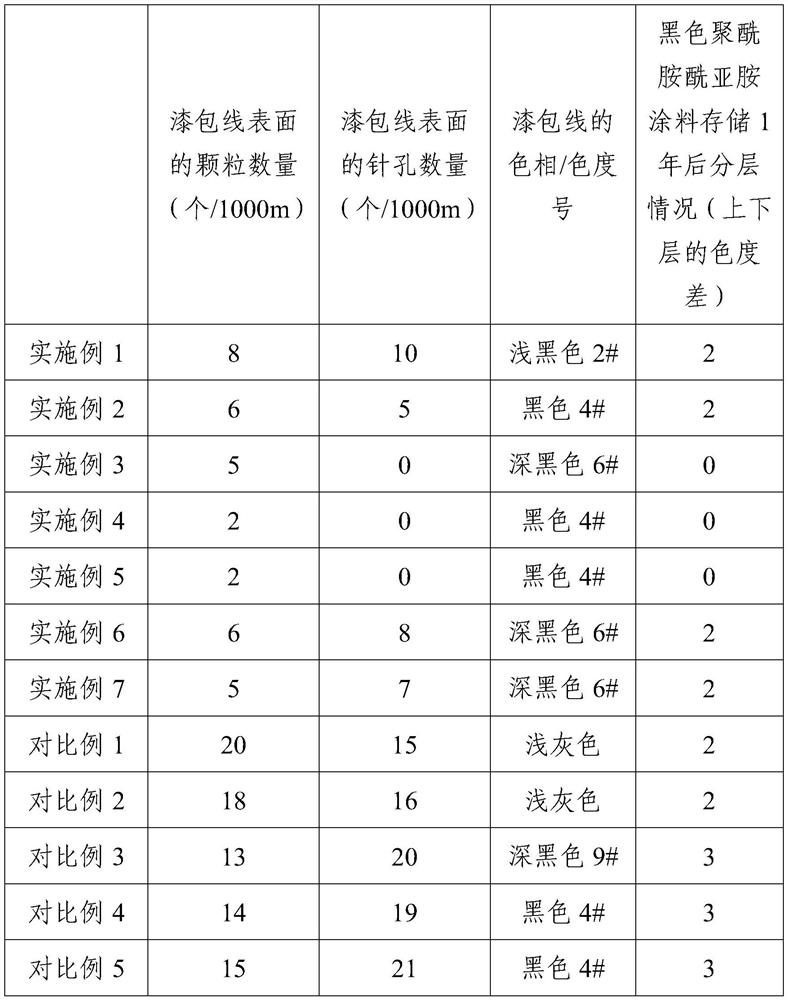

Examples

Embodiment 1

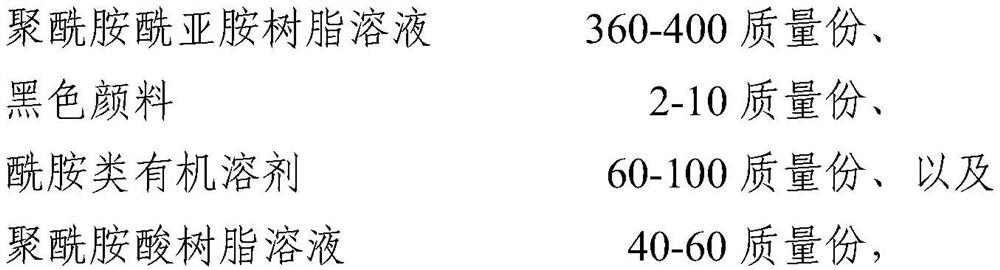

[0035] A kind of preparation method of black polyamide-imide paint, comprises the steps:

[0036] Add 2g carbon black, 60g N-methylpyrrolidone in the homogenizer, then grind 2h under rotating speed 3000rpm, then add 360g polyamideimide resin solution (polyamideimide resin solid content 30wt%), then heat up to 60 degrees Celsius, and then ultrasonically stirred and dispersed for 2 hours, wherein the ultrasonic frequency was 25 kHz, and then ground at a heating temperature of 60 degrees Celsius with a grinding wheel at a speed of 8000 rpm and a linear speed of 40 m / s for 2 hours. Filter with a 200-mesh filter screen to obtain a black polyamide-imide paint.

[0037] The preparation method of enameled wire, it comprises the steps:

[0038] Use a mold to coat the above-mentioned black polyamide-imide paint on the ∮0.4mm copper wire. The number of coats is 8 times, and it can be recoated several times. Place it in a 3.8m baking oven for baking. The inlet and outlet temperatures we...

Embodiment 2

[0040] A kind of preparation method of black polyamide-imide paint, comprises the steps:

[0041] Add 5g carbon black, 80g N-methylpyrrolidone in the homogenizer, then grind 2h under rotating speed 3000rpm, then add 360g polyamideimide resin solution (polyamideimide resin solid content 36wt%), then heat up to 60 degrees Celsius, and then ultrasonically stirred and dispersed for 1.5 hours, wherein the ultrasonic frequency was 23 kHz, and then ground at a heating temperature of 80 degrees Celsius at a speed of 8000 rpm and a linear speed of 40 m / s for 2 hours. Filter with a 200-mesh filter screen to obtain a black polyamide-imide paint.

[0042]Use a mold to coat the above-mentioned black polyamide-imide paint on the ∮0.4mm copper wire. The number of coats is 8 times, and it can be re-coated several times. Place it in a 3.8m baking furnace for baking. The inlet and outlet temperatures were 440 and 480 degrees Celsius respectively, the baking time was 1 minute, and the moving li...

Embodiment 3

[0044] A kind of preparation method of black polyamide-imide paint, comprises the steps:

[0045] Add 10g carbon black, 98g N-methylpyrrolidone in the homogenizer, then grind 2h under rotating speed 3000rpm, then add 400g polyamideimide resin solution (polyamideimide resin solid content 33wt%), then heat up to 70 degrees Celsius, and then ultrasonically stirred and dispersed for 1.5 hours, wherein the ultrasonic frequency was 23kHz, and then 40g of polyamic acid resin solution (polyamic acid resin solid content 30wt%) was added, and then at a heating temperature of 70 degrees Celsius, at a speed of 8000rpm, 40m / s line speed grinding for 2.5 hours. Filter with a 200-mesh filter screen to obtain a black polyamide-imide paint.

[0046] The preparation method of enameled wire, it comprises the steps:

[0047] Use a mold to coat the above-mentioned black polyamide-imide paint on the ∮0.4mm copper wire. The number of coats is 8 times, and it can be re-coated several times. Place ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com