Ternary oxide nano material, ternary oxide nano structure and preparation method thereof

A ternary oxide and nanostructure technology, which is applied in the field of ternary oxide nanostructures, can solve the problems of significant impact on the performance of nanostructure arrays, limited applications, and high costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

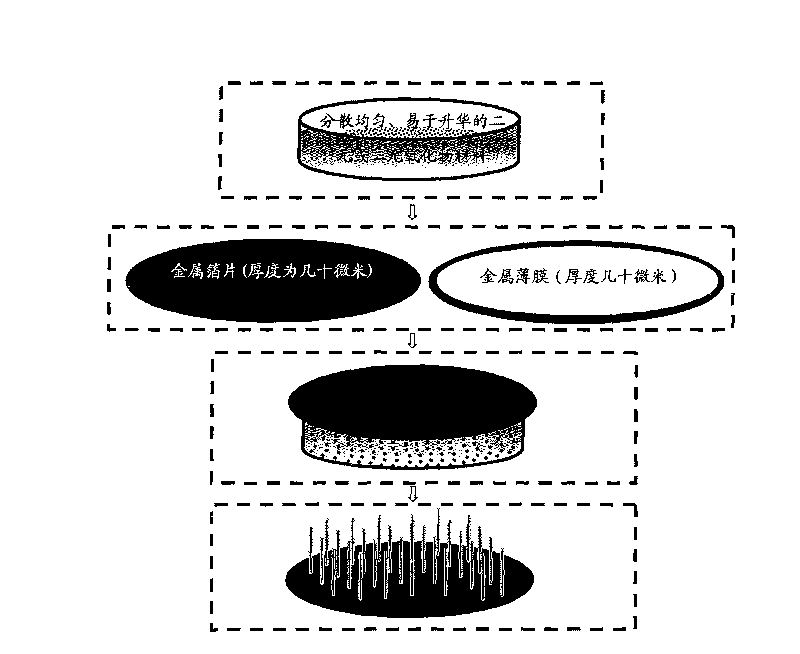

Method used

Image

Examples

Embodiment 1

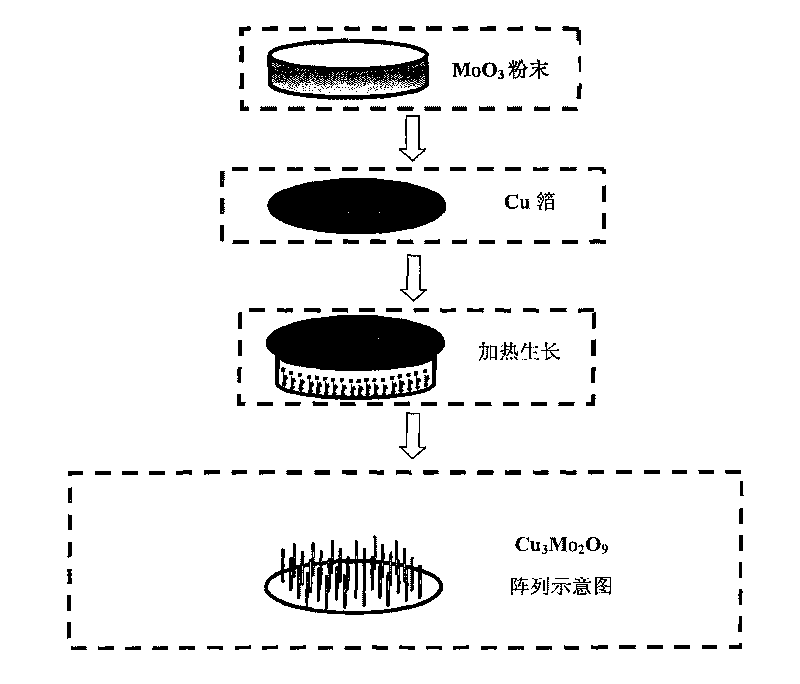

[0028] Using MoO with a purity of 99.99% produced by Beijing Chemical Reagent Company 3 The powder is an oxide of metal B, and the metal foil is a copper foil with a purity of 99.9% and a thickness of about 100 microns produced by China Chemical Reagent Co., Ltd., with a diameter of 10 cm. Among them, the copper foil is used as both the substrate and one of the reaction components.

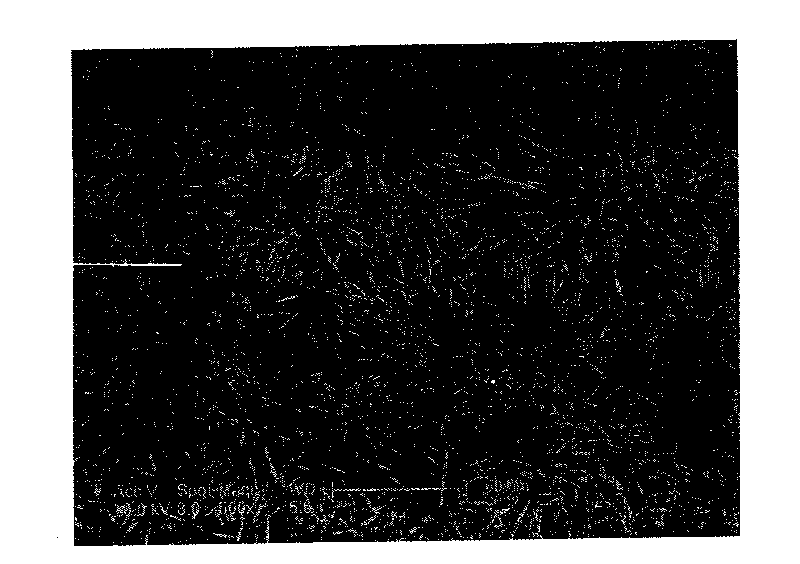

[0029] The preparation of the ternary oxide nanostructures of the present invention is carried out in air. In the air, the copper foil was placed in the MoO 3 On the crucible of the powder, the crucible was heated to 500°C for 2 hours, the crucible was taken out, and Cu was formed on the copper foil.3 Mo 2 o 9 The ternary oxide nanowire material, the nanomaterial is in the form of an array or a quasi-array, for specific forms see image 3 Cu 3 Mo 2 o 9 Photographs of nanomaterials. Figure 4 Shows the elemental analysis diagram of the ternary oxide nanowire material prepared by this method,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com