Nano-beta molecular sieve with low Si/Al ratio and preparation method thereof

A beta molecular sieve and molecular sieve technology, applied in the field of preparation of nano beta molecular sieve, can solve the problems of aggravated coking and deactivation, and achieve the effects of inhibiting coking, reducing usage, and reducing synthesis cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] (1) Preparation of reaction mixture gel

[0025] Add the FAU molecular sieve to the template agent (tetraethylammonium bromide) aqueous solution with a concentration of 0.4~3mol / L, the solid-liquid ratio of the FAU molecular sieve and the template solution is 1g: (4~20)mL, stir evenly, and then Add a small amount of concentrated ammonia water, the volume of which accounts for 6-12% of the volume of the template solution, and stir for 1-4 hours. Then add the silicon source, stir evenly, and make a reaction mixture gel, and the final molar ratio of each component is as follows: (3-25) SiO 2 :Al 2 o 3 : (1~4)Na 2 O:(2~10)TEABr:(100~600)H 2 O.

[0026] The FAU molecular sieve described here includes NaX molecular sieve and NaY molecular sieve with low silicon-aluminum ratio, and the silicon-aluminum ratio of the FAU molecular sieve is 1.02-2.6. The silicon source is selected from white carbon black, silica sol or a mixture of the two.

[0027] (2) Crystallization

...

Embodiment 1

[0033]Firstly, 9 g of NaX molecular sieve (Si / Al molar ratio is 1.1) is added into 120 mL of tetraethylammonium bromide aqueous solution (concentration is 1 mol / L), and stirred evenly. Then 7 mL of concentrated ammonia water was added to the above solid-liquid mixture, and stirred for 3 hours. Then add 35mL silica sol (w(SiO 2 )=30%) and stir evenly. The mixture was transferred into an autoclave for hydrothermal crystallization at 140°C for 48 hours. The resulting product was centrifuged and washed with distilled water until neutral. Finally, the obtained solid was dried at 100° C. for 12 hours to obtain nano-β molecular sieves.

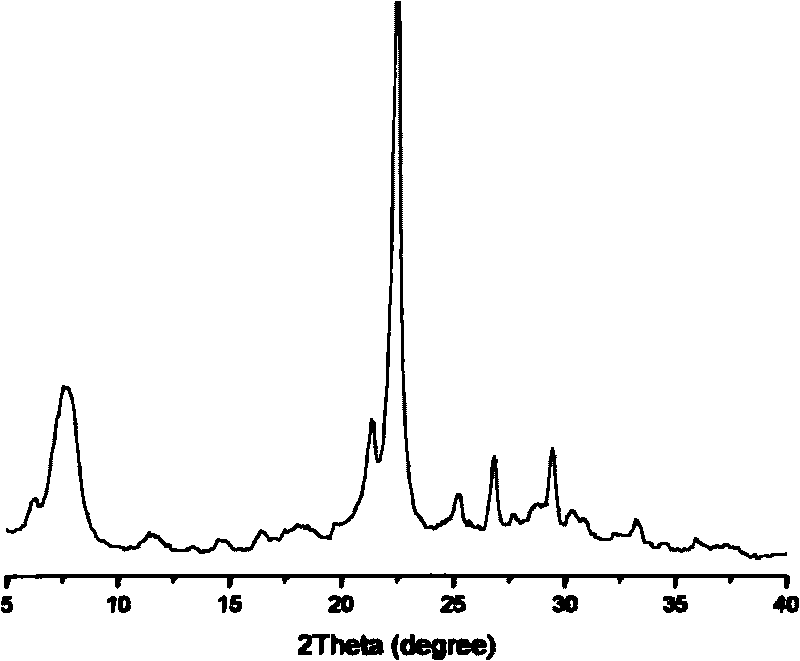

[0034] The XRD spectrogram and scanning electron micrograph of this nanometer β molecular sieve are as figure 1 , 2 shown. from figure 1 It can be seen that the characteristic peaks of β molecular sieves are quite obvious. from figure 2 It can be seen that the grain size of β molecular sieve is mostly concentrated between 120 and 200 nm, an...

Embodiment 2

[0036] First, add 10 g of NaX (Si / Al molar ratio is 1.1) into 120 mL aqueous solution of tetraethylammonium bromide (concentration: 1.1 mol / L), and stir evenly. Then 7 mL of concentrated ammonia water was added to the above solid-liquid mixture, and stirred for 3 hours. Then add 45mL silica sol (w(SiO 2 )=30%) and stir evenly. The mixture was transferred into an autoclave for hydrothermal crystallization at 137°C for 45 hours. The resulting product was centrifuged and washed with distilled water until neutral. Finally, the obtained solid was dried at 100° C. for 12 hours to obtain nano-β molecular sieves.

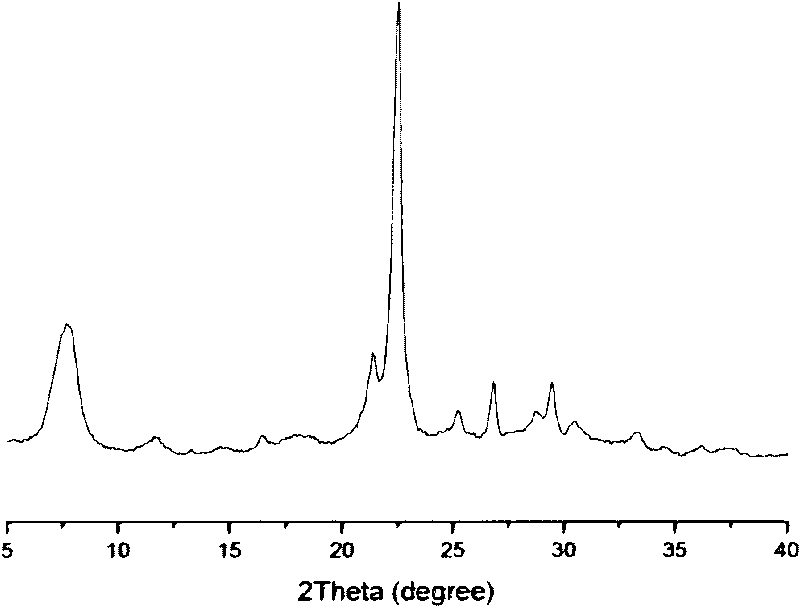

[0037] The XRD spectrogram and scanning electron micrograph of this nanometer β molecular sieve are as image 3 , 4 shown. from image 3 It can be seen that the characteristic peaks of β molecular sieves are quite obvious. from Figure 4 It can be seen that the grain size of β molecular sieve is mostly concentrated between 100-140nm, and the grain shape is spherica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com