Method for quickly synthesizing block graded pore structural nitrogenous porous carbon

A pore structure and graded technology, which is applied in the field of rapid synthesis of bulk porous carbon, can solve the problems of high energy consumption, long synthesis time, and cumbersome carbon material molding, and achieve the effect of short synthesis cycle and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] First, dissolve 3g resorcinol in 10ml water, then weigh 1.0g lysine and dissolve it in 5ml water; at room temperature, add the lysine solution into the resorcinol solution and stir for 10min to obtain a colorless transparent solution ; Then, under stirring conditions, 4.42g of formaldehyde was quickly injected into the above solution, and the solution changed from colorless and transparent to a white polymer block in an instant; after being dried at 50°C for 24 hours, it was carbonized, and protected from room temperature with an inert gas at 1°C / min Rising to 400°C, drying at a constant temperature for 60 minutes; then raising the temperature from 400°C to the final carbonization temperature of 800°C at a rate of 1°C / min, and holding a constant temperature for 120 minutes to obtain a bulk porous carbon with shape retention. The nitrogen adsorption test results show that Surface area 550m 2 g -1 , pore volume 0.30cm 3 g -1 . figure 1 It is the digital photo of the n...

Embodiment 2

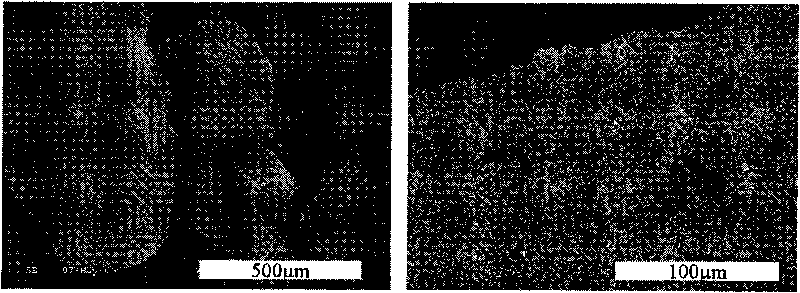

[0072] First, dissolve 3g resorcinol in 15ml water, then weigh 1.0g lysine and dissolve it in 5ml water; at room temperature, add the lysine solution into the resorcinol solution and stir for 10min to obtain a colorless transparent solution ; Then, under stirring conditions, 250 microliters of oleic acid was added dropwise to the above-mentioned system, the pH was adjusted to 6, and stirred for 30 minutes; 4.42g of formaldehyde was quickly injected into the above-mentioned solution, and the solution instantly changed from colorless and transparent to a white colloid; Aging in an oven at 50°C for 4 hours; carbonized after drying at 50°C for 24 hours, protected by an inert gas from room temperature at 1°C / min to 400°C, and drying at a constant temperature for 60 minutes; then at a rate of 1°C / min from 400°C to To the final carbonization temperature of 800°C and constant temperature for 120 minutes, the carbonization obtained a nitrogen-containing porous carbon with a low-density ...

Embodiment 3

[0074] First, dissolve 3g of resorcinol in 16ml of water, then weigh 150 microliters of ethylenediamine solution; add it into the resorcinol solution at room temperature, and stir for 10 minutes to obtain a colorless and transparent solution; then, under stirring conditions, Add oleic acid dropwise to the above system, adjust the pH to 6, and stir for 30 minutes; quickly inject 4.42g of formaldehyde into the above solution, and the solution changes from colorless and transparent to white colloid in an instant; transfer it to an oven at 50°C for gel aging for 4 hours ; After drying at 50°C for 24 hours, carbonize, protect with inert gas from room temperature to 400°C at a rate of 1°C / min, and dry at a constant temperature for 60 minutes; Constant temperature for 120min, carbonization to obtain nitrogen-containing porous carbon with low-density hierarchical pore structure, nitrogen adsorption test results show that the specific surface area is about 650m 2 g -1 , the pore volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com