Preparation method of Cu2ZnSnSxSe4-x nanocrystal

A nanocrystal and reactant technology, applied in the field of solar photovoltaic materials, can solve the problems of few nanocrystal reports, and achieve the effects of good crystallinity, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

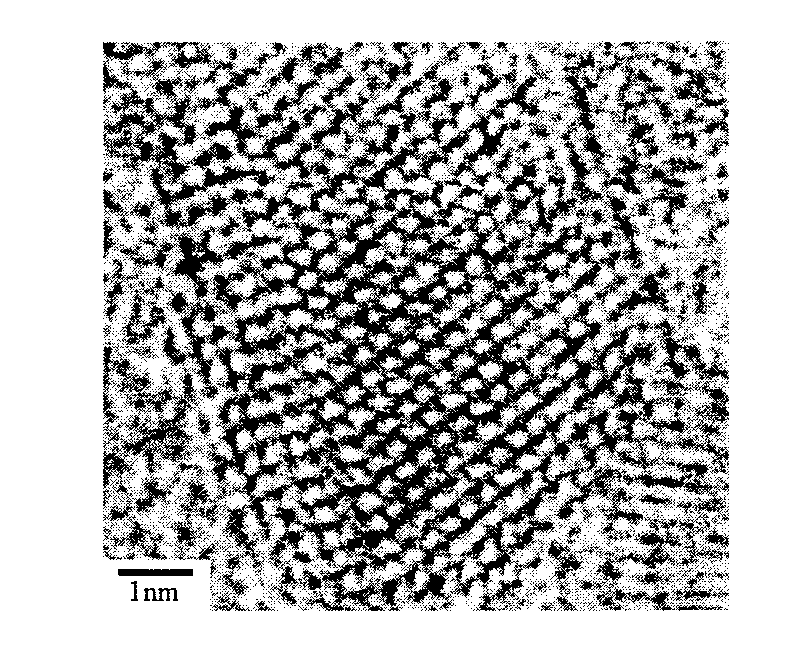

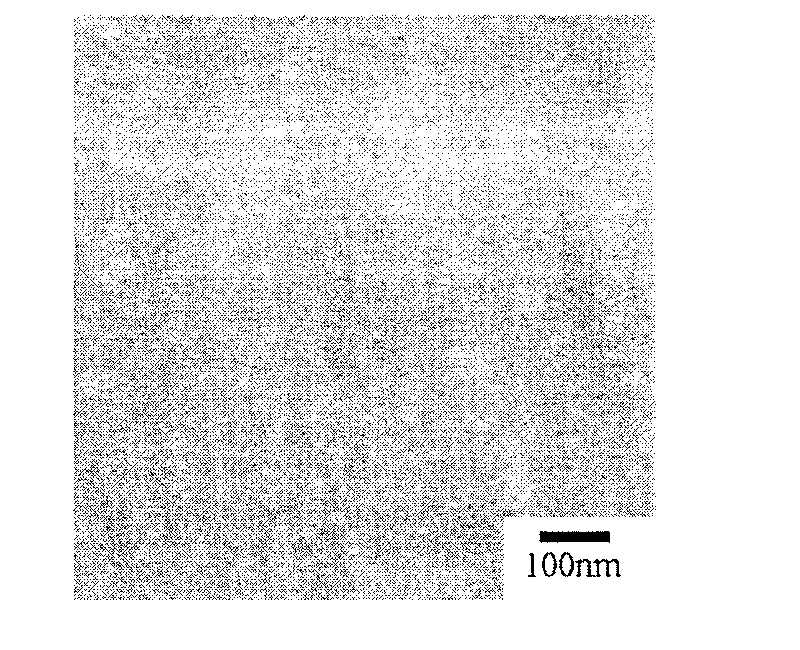

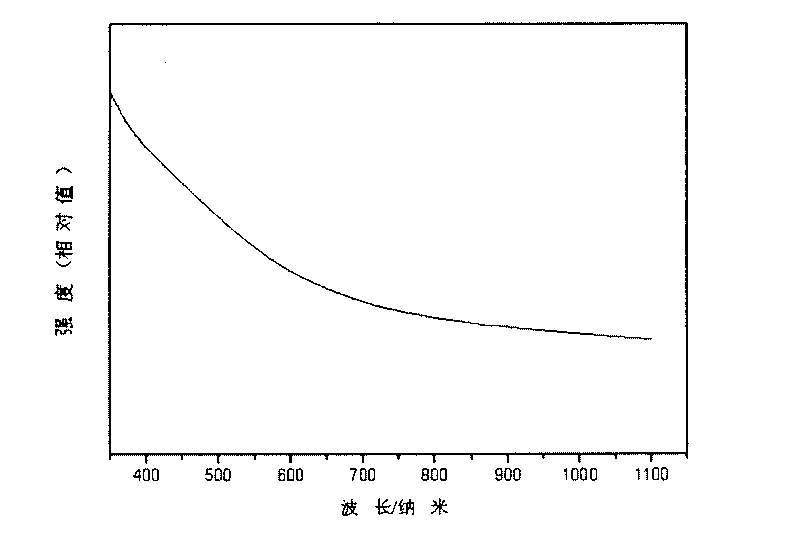

Embodiment 1

[0019] 12 ml of oleylamine was added to a 50 ml three-necked round bottom flask connected to a Schlenk line apparatus, and the temperature was raised to 130°C for 30 minutes under argon atmosphere. The reactant precursors 0.2 mmol copper acetylacetonate, 0.1 mmol zinc acetate, 0.1 mmol tin tetrachloride and 0.4 mmol sulfur powder were successively added to the reaction flask, and the reaction temperature was slowly raised to 280 in an argon atmosphere. The reaction was carried out at °C for 20 minutes, the heating device was removed, the reactant was cooled to 80 °C, and methanol was added to the cooled reactant to precipitate the nanoparticles. The nanocrystals were then collected by centrifugation at 12,000 rpm for 3 minutes, the suspension was poured into another container, and the final precipitate was dispersed in chloroform.

Embodiment 2

[0021] 12 ml of oleylamine was added to a 50 ml three-necked round bottom flask connected to a Schlenk line apparatus, and the temperature was raised to 130°C for 30 minutes under argon atmosphere. The reactant precursors 0.2 mmol copper acetylacetonate, 0.1 mmol zinc acetate, 0.1 mmol tin tetrachloride and 0.4 mmol hexamethyldisilazane were successively added to the reaction flask, and the reaction temperature was slowed down in an argon atmosphere. The temperature was raised to 270 °C for 15 minutes, the heating device was removed, the reactant was cooled to 80 °C, and methanol was added to the cooled reactant to precipitate the nanoparticles. The nanocrystals were then collected by centrifugation at 12,000 rpm for 3 minutes, the suspension was poured into another container, and the final precipitate was dispersed in chloroform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com