Grinding head mechanism for numerical control water drill grinding machine

A grinding machine and grinding head technology, which is applied in the direction of grinding machines, machine tools suitable for grinding workpiece edges, grinding workpiece supports, etc., can solve the problems of small single processing volume, inconvenient operation, time-consuming and laborious, etc., and achieve large processing volume , reduce manual operations, and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

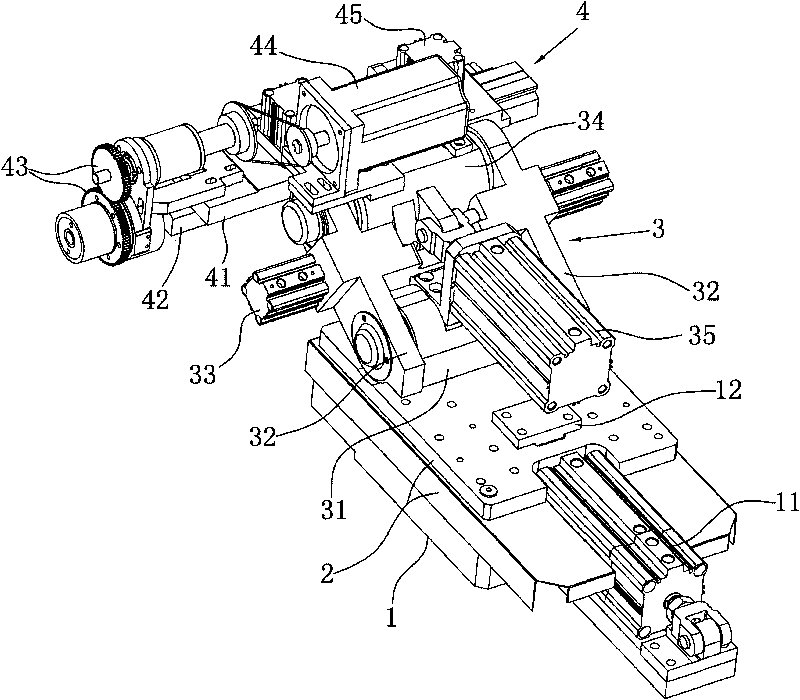

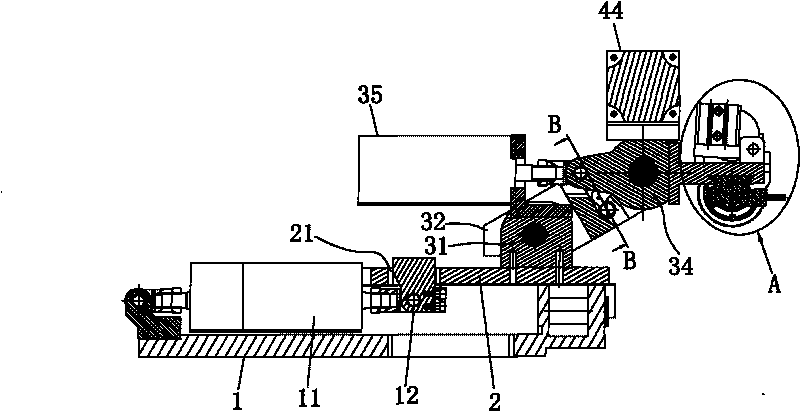

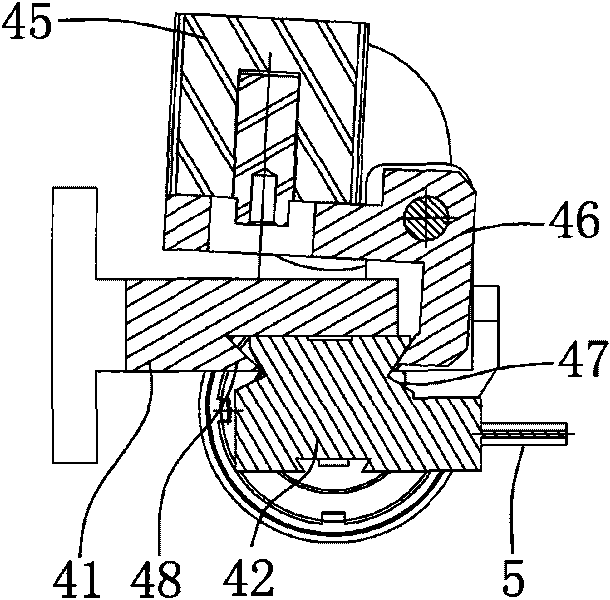

[0021] Such as figure 1 , figure 2 , Figure 5 As shown, the present invention is a grinding head mechanism for a CNC water drilling grinder, including a base plate 1 for connecting with the grinder frame, a horizontal propulsion mechanism is arranged on the base plate 1, and a connecting mechanism 3 is hinged on the horizontal propulsion mechanism. The other end of the connecting mechanism 3 is hinged with a clamp head 4, and a screw mandrel 49 is installed in the clamp head 4, and one end of the screw mandrel 49 is connected to the indexing motor 44 arranged on the connecting mechanism 3 through a transmission assembly, and the inside of the clamp head is along the The screw rod 49 has a plurality of clamp pins 5 arranged in parallel axially, and the clamp pins 5 are vertically engaged with the screw rod 49 . The tail of the clamp needle 5 is engaged with the screw rod by a worm gear structure, and its specific structure is a known technology, so it will not be described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com