A large-capacity dry food stir-frying equipment with cylinder circulation

A large-capacity, dry goods technology, applied in the fields of application, food processing, food science, etc., can solve the problems of increased workload, tooth damage, inseparability, etc., to achieve convenient loading and unloading, large processing volume, and strong versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

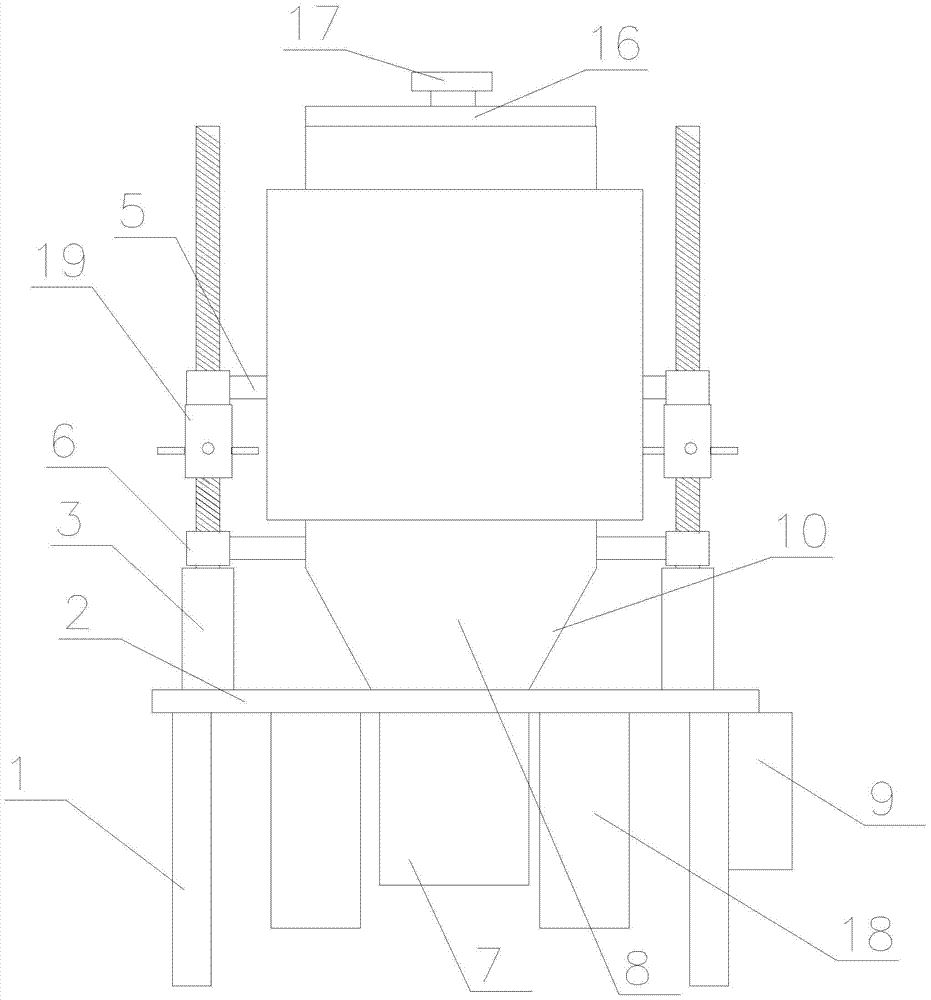

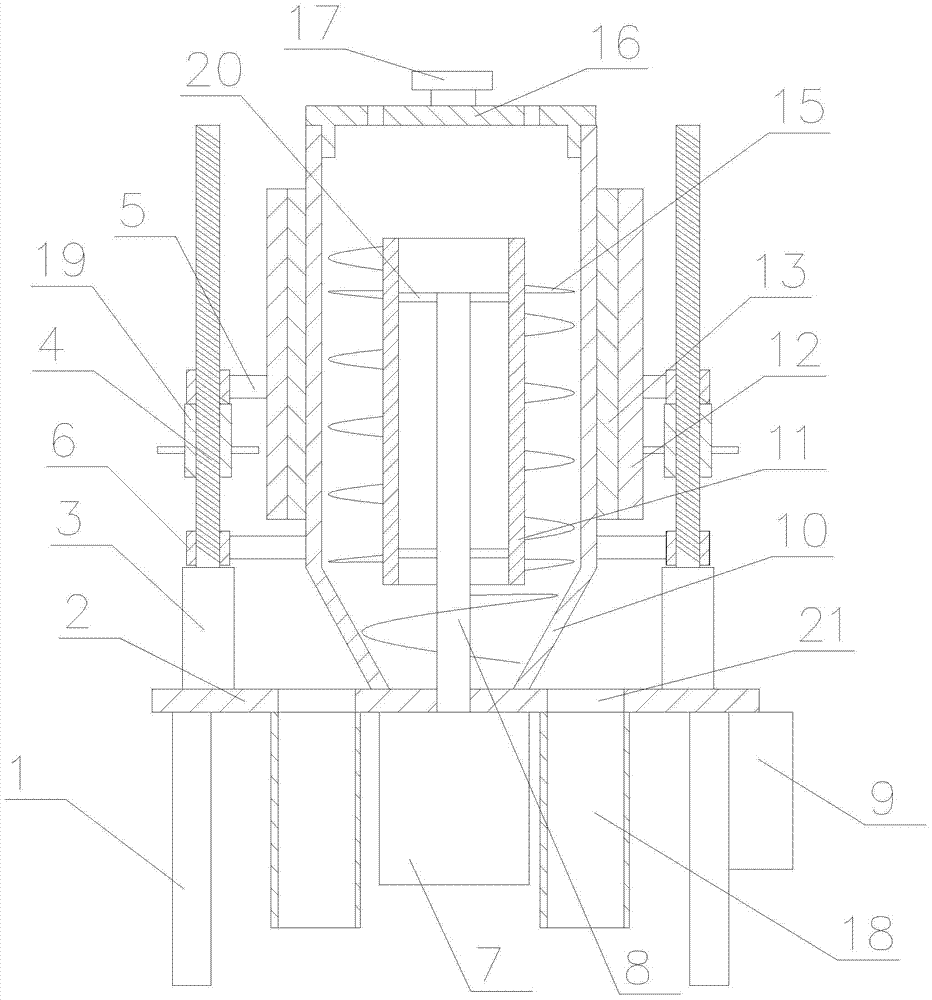

[0017] refer to figure 1 and figure 2 , the present invention is a large-capacity dry goods stir-frying equipment with cylinder circulation, which includes a lower leg 1, a spiral blade 15, a heat preservation cover 16, a cover handle 17, a screw cylinder 19, a connecting rod 20, a workbench 2, a limit block 3, Threaded guide rod 4, lifting arm 5, sliding sleeve 6, feeding motor 7, main shaft 8, electric control box 9, main turning barrel 10, lifting barrel 11, heat preservation sleeve 12 and heating wire 13, described The workbench 2 is circular, and the lower part of the workbench 2 is provided with four lower legs 1, the height of the workbench 2 is 100-300mm, and the electric control box 9 is installed on the lower leg 1. A timer, a relay and a circuit switch are arranged in the control box 9, and the circuit switch is respectively connected with the timer and the relay through wires, and 1-3 threaded guide rods 4 are arranged on the edge of the workbench 2, and the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com