A kind of preparation method of high-quality aluminum alloy welding wire

A kind of aluminum alloy welding wire, high-quality technology, applied in the field of welding materials, can solve the problems that affect the welding quality of joints in automatic welding production, it is difficult to ensure the quality of aluminum alloy welding wire, and it is difficult to obtain high-quality surfaces, etc., so as to improve welding efficiency and weld joints Reasonable quality, deflection control, and precise roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

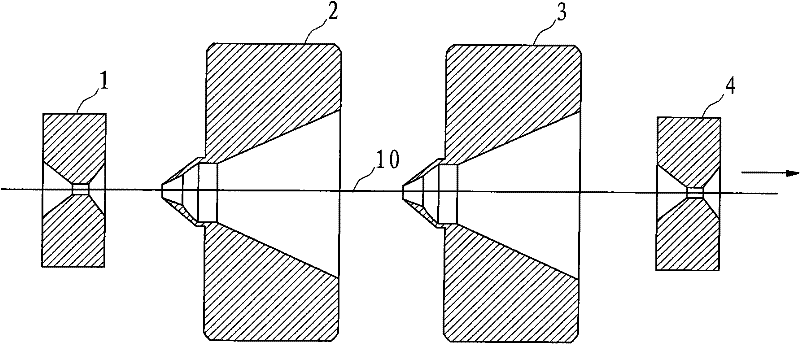

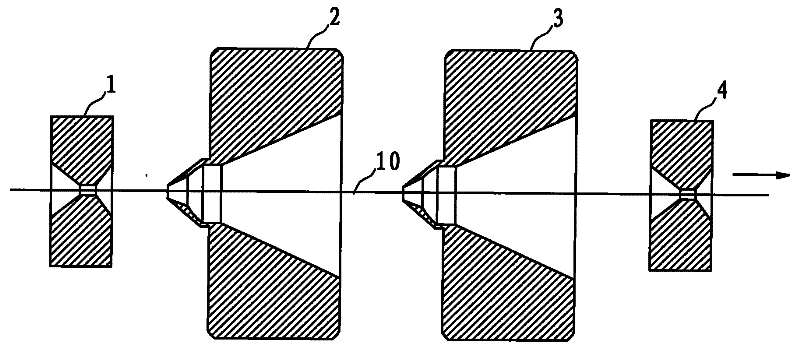

[0018] The preparation method of the aluminum alloy welding wire in the present embodiment, as figure 1 As shown, the following steps are included in sequence:

[0019] ①Draw the aluminum alloy welding wire to a suitable size, then pass the welding wire through a mold made of tungsten steel for 8 or 10 times of drawing, and the area shrinkage rate between each pass is 16-18% , and the amount of deformation between each pass should be exactly the same.

[0020] ② Pass the continuously drawn aluminum alloy welding wire through the sizing die 1. The material of the sizing die 1 is diamond, and its dimensional tolerance is ±0.002mm.

[0021] ③Put the aluminum alloy welding wire passing through the sizing mold through the scraping mold for scraping treatment. The material of the scraping mold is tungsten steel, and its dimensional tolerance is ±0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com