Method for preparing rhizoma drynariae/pig bone powder/chitosan compound bracket material

A technology of scaffold material and drynaria, applied in scaffolds, medical science, prostheses, etc., can solve problems such as difficulties in processing and forming derived bone, restrictions on the application of heterogeneous bone, and impact on strength, so as to promote bone cell formation ability and improve mechanical strength. performance, pH stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

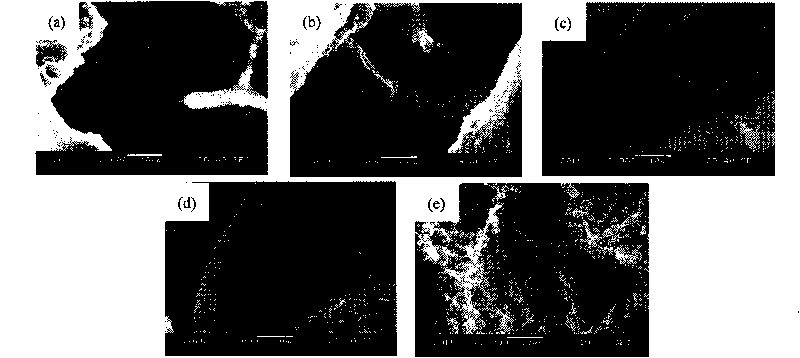

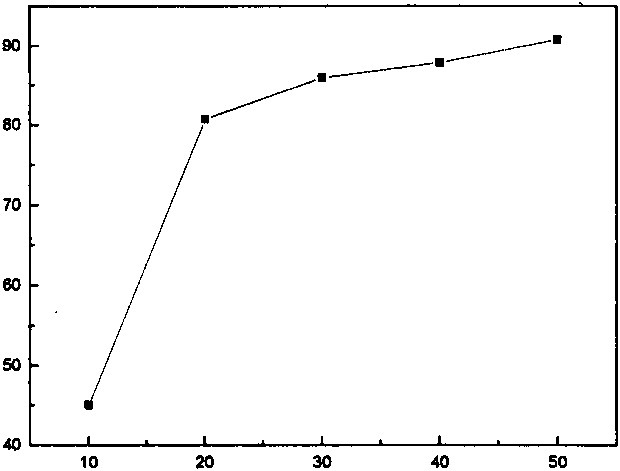

Image

Examples

Embodiment 1

[0056] Embodiment 1: Preparation of Chinese medicine Rhizoma Rhizoma Drynariae (powder) / pork bone powder (porcine bone type hydroxyapatite) / chitosan composite scaffold material (change the content of chitosan)

[0057] Firstly, pig bones are pretreated, degreased, decalcified, calcined, and ball milled to obtain pig bone powder (pork bone type hydroxyapatite), and drynaria rhizome is crushed into small particles, and then ball milled with a planetary ball mill for 3 hours, and then used Grinding in an agate mortar, passing through a 200-mesh sieve and then bagging for subsequent use, followed by the dissolving of chitosan, which is dissolved with 2% acetic acid solution. Then chitosan is modified with chelating type pyrophosphate titanate coupling agent (NDZ-311), and the consumption of chelating type pyrophosphate titanate coupling agent (NDZ-311) is 1wt of chitosan %, after two hours of magnetic stirring, the mixed powder of porcine hydroxyapatite and Drynaria fortunei (cons...

Embodiment 2

[0058] Embodiment 2: Preparation of Chinese medicine Rhizoma Drynariae (powder) / pork bone powder (porcine bone type hydroxyapatite) / chitosan composite scaffold material

[0059] First, chitosan is modified with chelating pyrophosphate titanate coupling agent (NDZ-311), and the consumption of chelating pyrophosphate titanate coupling agent (NDZ-311) is 1wt of chitosan %, after two hours of magnetic stirring, the mixed powder of porcine-type hydroxyapatite and drynaria (consumption is 1 / 10 of the total amount of porcine-type hydroxyapatite and CS) is mixed with porcine-type hydroxyapatite The ratio of CS to 8:2 was poured into the chitosan solution, and after four hours of magnetic stirring, the mixture was evenly stirred with a glass rod to achieve uniform dispersion to obtain a viscous solution. Pour the solution into the mold, then put it in the refrigerator to pre-cool at -85°C for about 24 hours, then put it into a low-temperature freezer immediately after taking it out, an...

Embodiment 3

[0060] Embodiment 3: Preparation of Chinese medicine Rhizoma Drynariae (solvent) / pork bone powder (porcine bone type hydroxyapatite) / chitosan composite scaffold material

[0061] Firstly, pig bones are pretreated, degreased, decalcified, calcined, and ball milled to obtain pig bone powder (pork bone type hydroxyapatite), and drynaria rhizome is crushed into small particles, and then ball milled with a planetary ball mill for 3 hours, and then used Grinding in an agate mortar, passing through a 200-mesh sieve and then bagging for later use, followed by dissolving chitosan. Then chitosan is modified with chelating type pyrophosphate titanate coupling agent (NDZ-311), and the consumption of chelating type pyrophosphate titanate coupling agent (NDZ-311) is 1wt of chitosan %, after two hours of magnetic stirring, porcine-type hydroxyapatite is poured into the chitosan solution in the ratio of 8:2 by porcine-type hydroxyapatite: CS, and then the concentrated solution of drynaria is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com