New antioxidants for post-cmp cleaning formulations

A technology for removing compositions and solvents, applied in detergent compounding agents, detergent compositions, chemical instruments and methods, etc., can solve problems such as increasing dielectric constant and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0072] Embodiment (i): The ratio of quaternary base to corrosion inhibitor is from about 0.1:1 to about 10:1, preferably from about 0.5:1 to about 5:1, even more preferably from about 1:1 to about 2:1 ; The ratio of organic amine to corrosion inhibitor is about 0.1:1 to about 10:1, preferably about 0.5:1 to about 5:1, even more preferably about 2:1 to about 3:1;

[0073] Embodiment (ii): The ratio of quaternary base to complexing agent is about 1:1 to about 5:1, preferably about 2:1 to about 3.5:1; the ratio of organic amine to complexing agent is about 1:1 to about 10:1, preferably about 3:1 to about 7:1; the ratio of corrosion inhibitor to complexing agent is about 0.001:1 to about 0.5:1, preferably about 0.01:1 to about 0.1:1;

[0074] Embodiment (iii): The ratio of organic amine to corrosion inhibitor is about 0.1:1 to about 10:1, preferably about 1:1 to about 3:1;

[0075] Embodiment (iv): The ratio of organic amine to corrosion inhibitor is about 0.1:1 to about 10:1, pr...

Embodiment 1

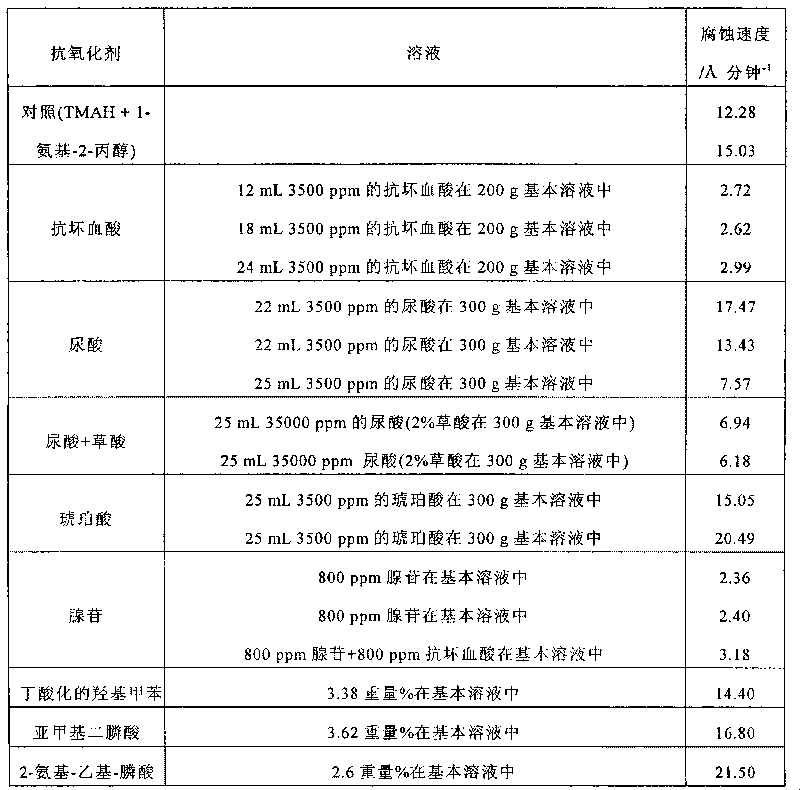

[0102] The covered PVD copper wafer was immersed in a solution consisting of a base solution containing TMAH, 1-amino-2-propanol and different antioxidants, and the corrosion rate of copper was determined using a potentiostat, where PVD Cu was the working electrode , the Pt sieve is the counter electrode, and the Ag / AgCl electrode is the reference electrode. The anodic corrosion rate of copper was calculated at an anodic voltage bias of 0.1 to 1.0 V compared to the open circuit potential. The results are summarized in Table 1 below.

[0103]

[0104] It can be seen that adenosine significantly reduces the corrosion rate of copper. Other advantages include, but are not limited to, minimized copper roughness, and stabilization of the copper(I) oxide surface after residue removal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com